Wing weight transfer adjustment, Cart weight transfer adjustment, Refer to figure 70 – Great Plains NTA2007HD Operator Manual User Manual

Page 90

86

Great Plains Manufacturing, Inc.

NTA607/2007HD

166-283M

04/04/2011

Hitch drill to suitable tractor (page 22). Hydraulic

power must be available for this adjustment.

2.

Unfold implement (page 31). The wing transfer

adjustment cannot be made with the wings folded.

Set circuit to Neutral.

3.

Lower drill (page 36) in representative field condi-

tions. Pull forward to put openers in ground.

4.

Open fan shut-off valve (page 56). Gradually bring

fan up to normal operating rpms.

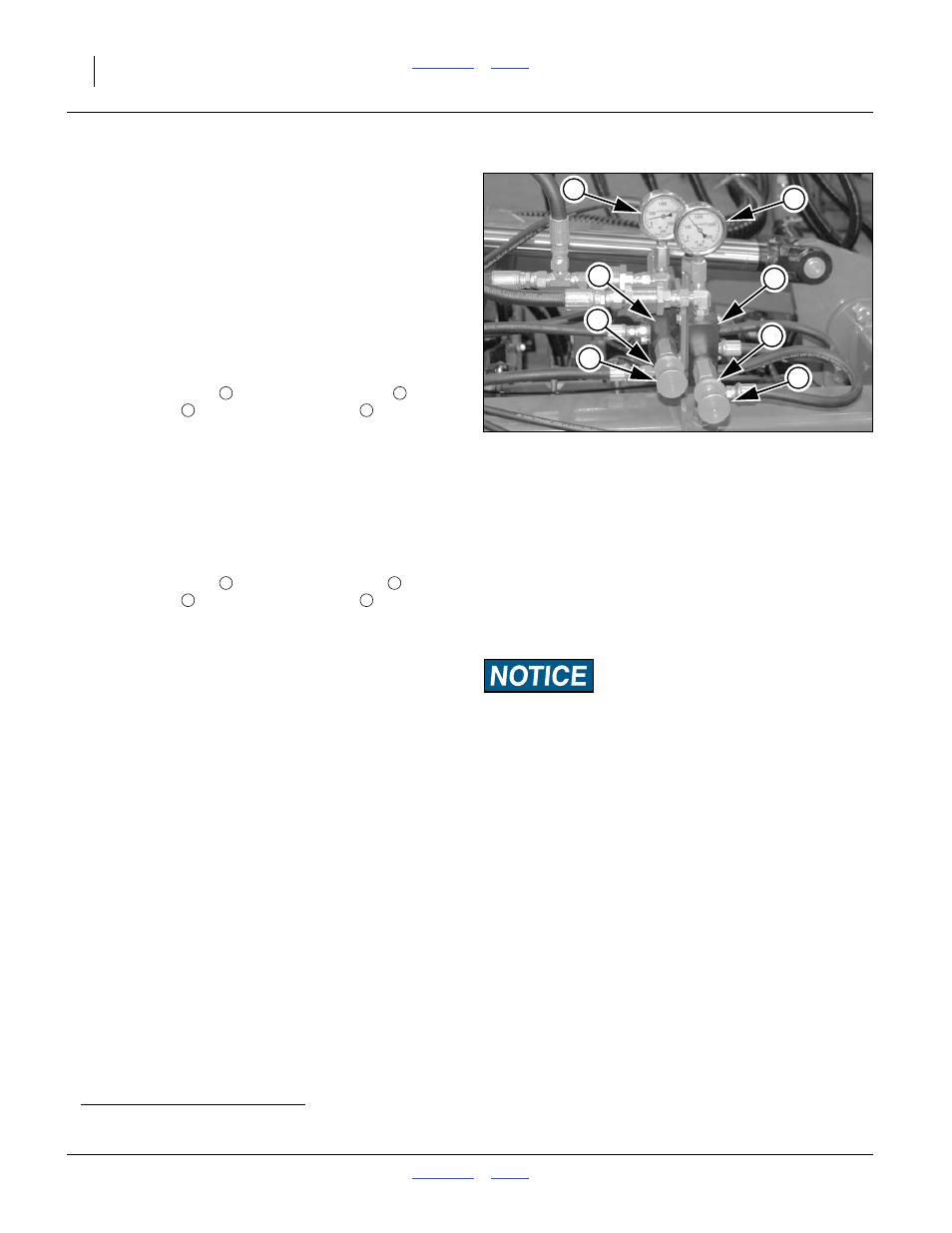

Wing Weight Transfer Adjustment

5.

Release lock ring

on wing-transfer valve

.

Adjust knob

while observing gauge

.

Increase weight transfer to wings by turning knob

clockwise. Reduce weight transfer to wings by turn-

ing knob counter-clockwise.

Set pressure to at least 250 psi.

Secure setting with lock ring.

Cart Weight Transfer Adjustment

6.

Release lock ring

on cart-transfer valve

.

Adjust knob

while observing gauge

.

Increase weight transfer from cart by turning knob

clockwise. Reduce weight transfer from cart by turn-

ing knob counter-clockwise.

Set pressure to at least 100 psi.

Secure setting with lock ring.

7.

Pull forward in ground. Assess opener penetration,

and coulter (option) penetration. Compare wings

a

to

center section.

8.

When satisfied with pressure reading, raise imple-

ment while watching pressure gauge. Gauge reading

should drop as you raise implement.

9.

During field operations, monitor coulter and opener

depth of wings and center section. Adjust weight

transfer as required for consistent depth across drill.

a. Wing operating height is also affected by a leveling eyebolt adjustment (page 129).

Null4:

Note: To avoid planting problems, do not exceed

1500 psi for wing-transfer, and 1000 psi for cart-

transfer. A relief valve prevents operating the wing-

transfer at over 1500 psi.

Material Rate Risk:

Do not set cart weight transfer higher than necessary.

Values close 1000 psi can lift the rear of an empty cart off the

ground. As a cart nears empty, the main tires can begin to slip,

or stop turning altogether, resulting in irregular seeding rates

or stoppages.

Figure 70

Weight Transfer Valves

31192

1

2

3

4

6

7

5

8

3

1

4

5

6

2

7

8