Bleeding lift hydraulics – Great Plains NTA2007HD Operator Manual User Manual

Page 119

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

115

04/04/2011

166-283M

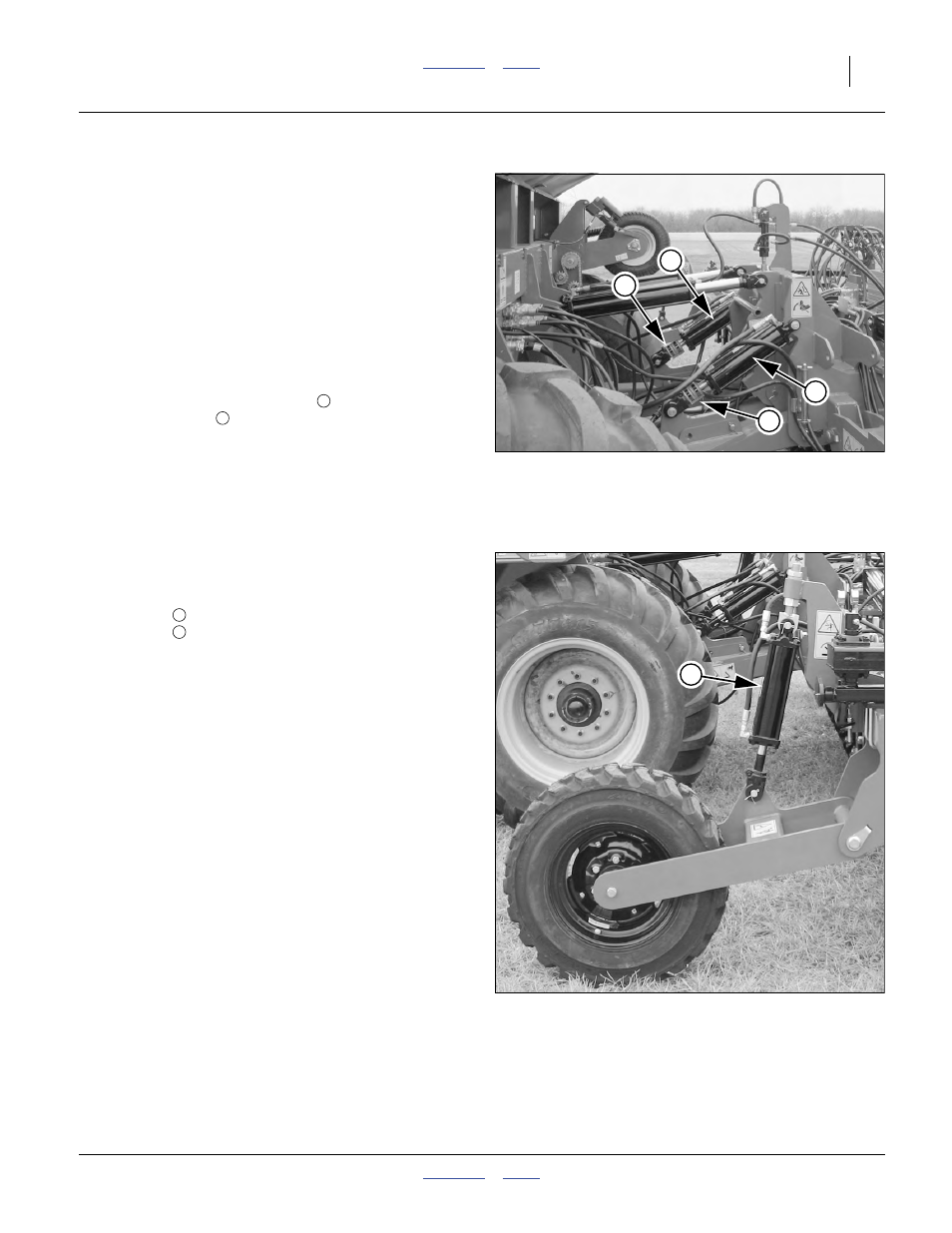

Bleeding Lift Hydraulics

Move the drill to a hard surface area, so that the imple-

ment cannot fully lower.

If the systems have sufficient fluid for safe operation,

prior to bleeding, perform an unfold (page 30). Leave the

implement raised.

1.

Review safety advisories and operational advice on

page 114, and on this page, before performing

bleed.

Note: A complete Lift system re-charge requires about

10 liters (2.6 gallons) of oil.

Refer to Figure 100 and Figure 101

2.

Record the number of spacers

on the rods of each

Master cylinder

. Remove and save the spacers (to

prevent the cylinders from resting on the spacers).

3.

Lower the implement.

If the lift cylinders bottom-out on the rod ends, it will

be necessary to use jacks or stands under the tool

bar. Raise the implement. Lower it on the supports.

4.

Set the Lift circuit to Float. Shut off tractor. Remove

key.

5.

Unpin the rod ends of both center section lift

cylinders

, and both wing gauge wheel lift

cylinders

.

6.

Orient the lift cylinder rod ends so that they are point-

ing up (at least slightly above horizontal) and cannot

strike drill parts at full extension. Fully extend the lift

cylinders. Hold for several seconds.

7.

Retract cylinders to their starting position. Set circuit

to Float. Re-connect rod ends. Re-install spacers.

Null4:

Figure 100

Master Lift Cylinders

31226

1

2

Null4:

Figure 101

Slave (Wing) Lift Cylinder

31228

3

2

3