Appendix c - option installation, Changing meter flutes – Great Plains NTA2007HD Operator Manual User Manual

Page 167

Great Plains Manufacturing, Inc.

163

04/04/2011

166-283M

Appendix C - Option Installation

Changing Meter Flutes

To order high rate flute shafts, see “High Rate Flute

Sets” on page 141. To install a set of these shafts (or re-

install the standard shafts), start with the front meter, as

the task is a bit easier there. Save all parts for re-use.

Hopper must be empty for this procedure. see “Unload-

ing Materials” on page 108.

Refer to Figure 147

1.

On the left end of the meter box, release the anti-

rotation strap

, and loosen the thumbscrew

2.

Remove and save the pins

from the final range

gears

, and then remove and save the gears.

Refer to Figure 148

3.

Remove and save the outer ring of six (6) self-tap-

ping hex head bolts

, that secure the outer flange

to the meter box.

Note: Do not remove the six bolts

that secure the bear-

ing flangette to the outer flange. The shaft to be in-

stalled includes its own flange.

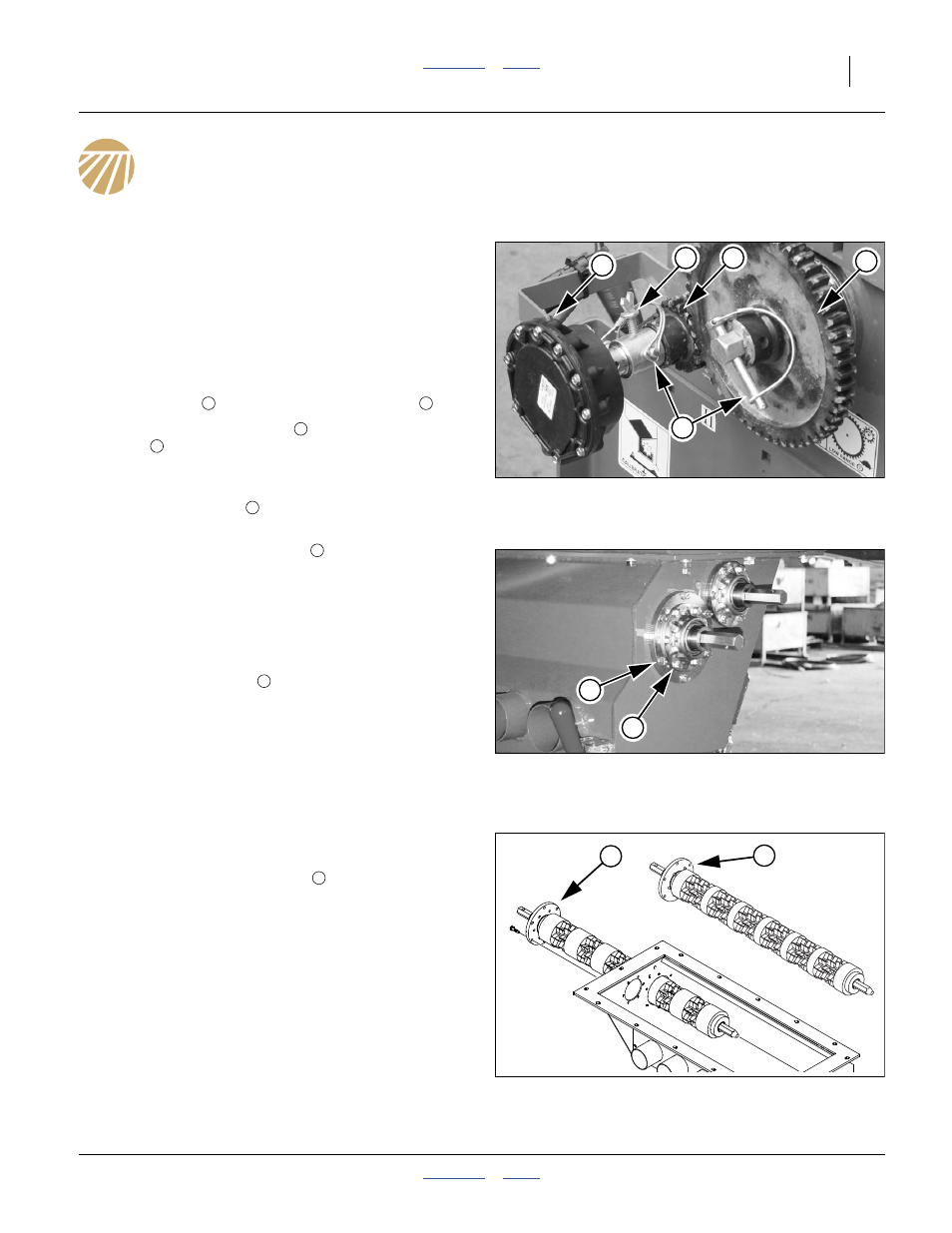

Refer to Figure 149 (Shown with meter box off and various

components removed for clarity. It is not necessary to dis-

mount or further disassemble meters to swap flute shafts).

4.

From the left end of the meter box, carefully withdraw

the current flute shaft

. It is likely that the flange

has a bead of silicone gasket. You may need to care-

fully pry the flange loose from the box.

5.

Store the old shaft in the carton in which the new

shaft was supplied. Mark the carton with the number

of active hoses (towers) and the number of stars

(factory standard is 2). This will reduce the risk of

mistaking the carton/contents in the future.

6.

Apply a bead of silicone sealant to the inside face of

the outer flange, just inside the bolt hole pattern.

7.

Carefully insert the new shaft

in the meter box.

8.

When the flange on the left end is fully seated

against the box, secure it with the 6 saved bolts. Give

the shaft a few turns.

9.

Re-mount the gears. Refer to the Seed Rate manual

for the gear assignments for the agitator and flute

shafts. Note the pin hole orientation on the shaft and

on the gears. The gears can only be pinned in 2 of

the 6 possible ways they can be placed on the

shafts.

Null4:

Figure 147

Remove Gears

31373

4

3

4

1

2

2

3

4

5

Null4:

Figure 148

Remove Flange Bolts

26338

6

5

6

7

Null4:

Figure 149

Exchange Flute Shafts

26335

7

6

6