Loading liquid fertilizer (option), Tank loading: all methods – Great Plains NTA2007HD Operator Manual User Manual

Page 54

50

Great Plains Manufacturing, Inc.

NTA607/2007HD

166-283M

04/04/2011

Loading Liquid Fertilizer (Option)

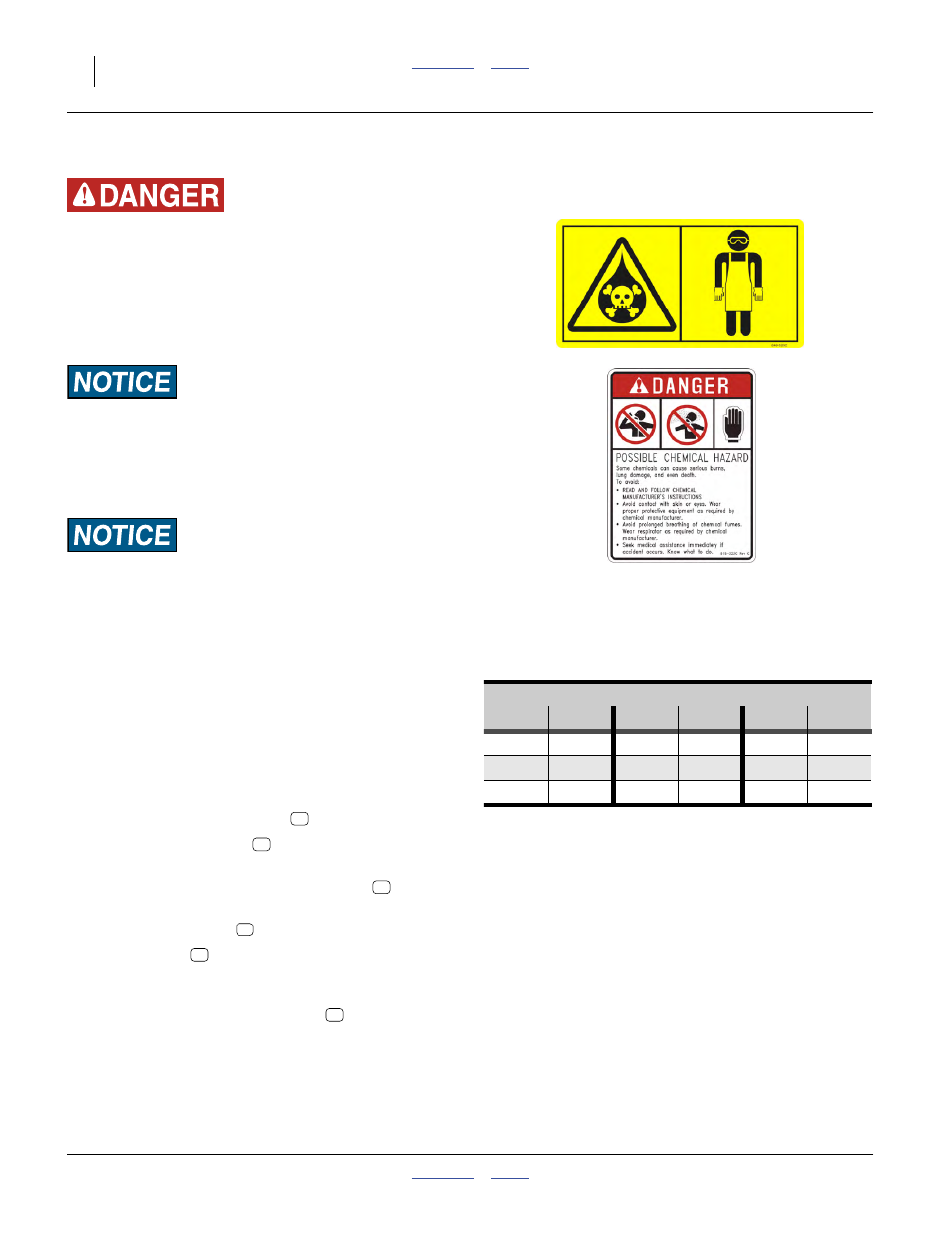

Agricultural Chemical Hazards:

Avoid contact with skin or eyes. Wear proper protective equip-

ment as required by chemical manufacturer. Avoid prolonged

breathing of chemical fumes. Wear respirator as required by

chemical manufacturer. Some chemicals will cause serious

burns, lung damage and death. Seek medical assistance imme-

diately if accident occurs. Know what to do in case of an acci-

dent.

Tongue Weight Hazard:

Hitch to tractor, or ensure that tongue jack is on an adequate

surface. Filling the liquid fertilizer tanks adds nearly 2200 kg

(4800 pounds) to the cart, much of which may be borne by the

tongue. On soft ground, or in the event of sudden rain, the

parking jack could sink into the ground.

Inconsistent Rate Risk:

Use only pre-mixed liquid fertilizers. If using a pre-mixed fer-

tilizer that tends to separate, sediment or stratify, load only

immediately before use. The tanks of the optional liquid fertil-

izer system do not include agitators.

Tank Loading: All Methods

Tank fill level is reported by a sight gauge on each tank.

The table at right converts the scale levels to liters.

Refer to Figure 44 on page 51 and Figure 143 on page 161

1.

Hitch cart and set tractor parking brakes. If filling

unhitched, make sure that tongue jack is on an ade-

quate surface. Block cart tires or set optional cart

brakes.

2.

Close quick-fill shutoff valve

at cart right.

3.

Close cart outlet valve

at cart rear.

4.

Determine the desired application rate. Select and

installed suggest drop-line orifice plates

(see

Seed and Fertilizer Rate Manual).

5.

Close shut-off valve

at pump.

6.

If the strainer

has not been serviced recently, per-

form that maintenance before loading material

(page 107).

7.

Open both tank discharge valves

, unless filling

only one tank at a time, in which case close the valve

for the tank not being filled.

Null4:

.

Note: With both tank valves open, any type of filling oper-

ation fills both tanks. At high fill rates, or if the drill is

parked across a slope, tank filling may be uneven.

Metric Equivalents: 200 Gallon Tank Scale

Gallons

Liters

Gallons

Liters

Gallons

Liters

200

755

125

475

50

190

175

660

100

380

25

95

150

570

75

285

15

55

31169

12

22

26

16

17

13