Weight transfer adjustments, Weight transfer safety information – Great Plains NTA2007HD Operator Manual User Manual

Page 89

Great Plains Manufacturing, Inc.

Adjustments

85

04/04/2011

166-283M

Weight Transfer Adjustments

Weight Transfer Safety Information

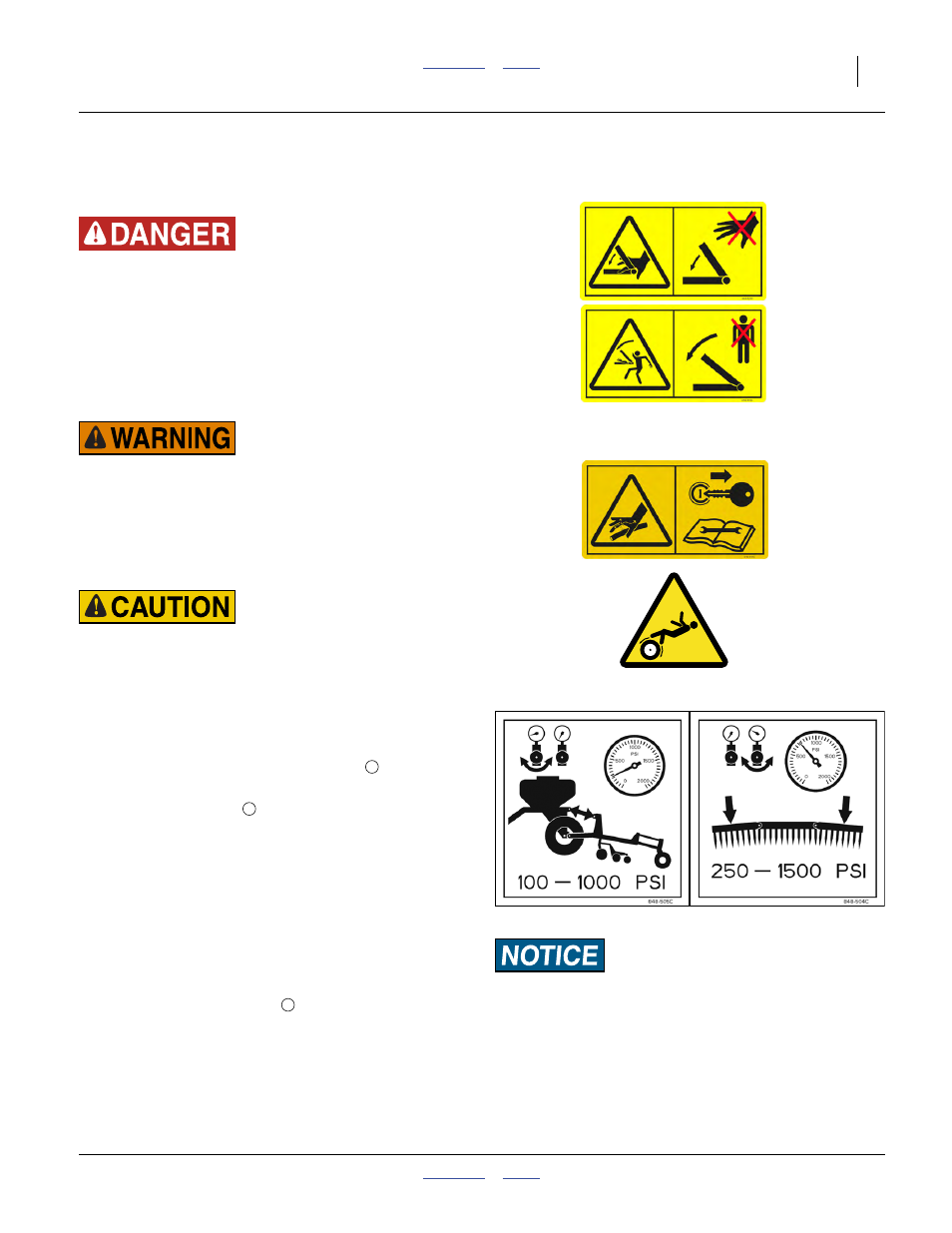

Crushing Hazards:

This adjustment requires working near the unfolded and low-

ered drill with the hydraulic system active. Assign two people

to this task, one in the tractor cab, ready to shut the tractor

down on hand signal from adjuster or any unplanned event.

Keep body parts clear of wings and openers while adjusting.

Keep all bystanders well away. You will be seriously injured or

killed if you are caught between lowering openers and ground,

or raising openers and drill frame.

High Pressure Fluid Hazard:

Escaping fluid under pressure can penetrate the skin causing

serious injury. Use a piece of paper or cardboard, NOT BODY

PARTS, to check for suspected leaks. Wear protective gloves

and safety glasses or goggles when working with hydraulic

systems. If an accident occurs, seek immediate medical atten-

tion from a physician familiar with this type of injury.

Falling Hazard - Tires Not a Step:

Do not use tires as steps or platforms. At higher transfers, cyl-

inders can lift cart wheels sufficiently for them to spin.

Refer to Figure 70 on page 86

During field operations, the Fold cylinders distribute cen-

ter section weight to the wings. The wings are much

lighter than the center section, and some weight needs

to be transferred. The wing-transfer valve

controls the

amount of weight transferred.

The wing transfer valve

needs an initial setting and

possible later adjustment. If insufficient weight is trans-

ferred, the wings run higher than the center section. If

excess weight is transferred, the center runs higher.

The center section lift lock and cart-transfer functions

share a hydraulic circuit. There needs to be some pres-

sure in this circuit for a pilot-operated check valve to

switch between functions. Also, at higher row unit down-

forces, there may be insufficient total implement weight.

A pair of cylinders between the cart and implement allow

some of the cart weight to be transferred to the imple-

ment. The cart-transfer valve

controls this weight

transfer.

The cart transfer valve may often be left at the nominal

100 psi value.

Material Rate Risk:

The cart transfer cylinders can un-weight the cart sufficiently

to cause ground drive slippage, and in extreme cases, actually

lift the cart wheels off the ground.

1

1

2