Field operations, Final field checklists – Great Plains NTA2007HD Operator Manual User Manual

Page 64

60

Great Plains Manufacturing, Inc.

NTA607/2007HD

166-283M

04/04/2011

Field Operations

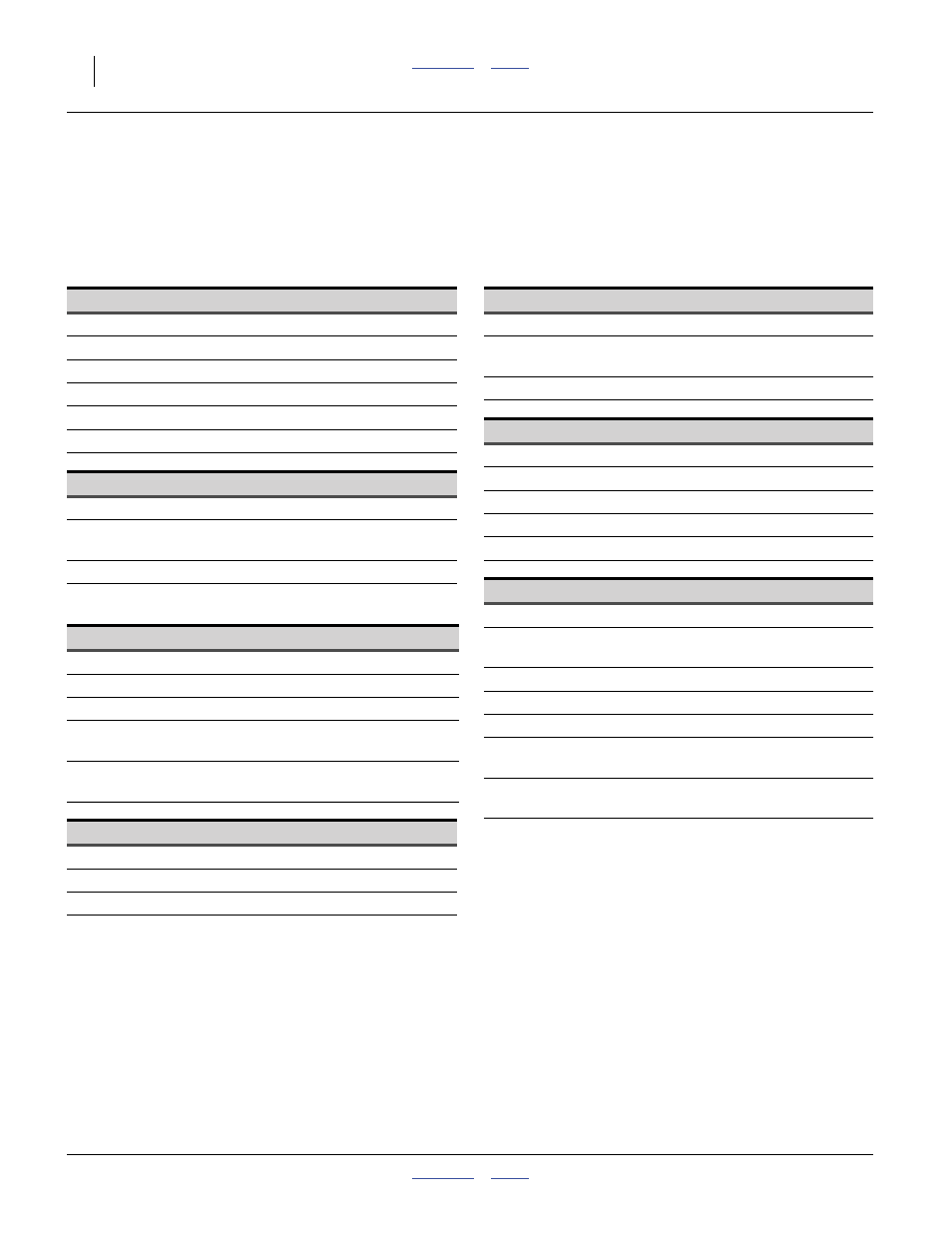

Final Field Checklists

Use the following tables to develop a final checklist for

your tractor/air drill configuration.

Additional or fewer steps may be necessary depending

on tractor features, air drill options and planting accesso-

ries.

Null4.aac:

Null4:

Null4:

Null4:

Null4:

Null4:

Null4:

Null4:

Mechanical Checklist

Page

❑ Check all tire pressures

❑ Tongue height preset

❑ Implement unfolded

❑ Marker extension set

❑ Marker disk angle set

❑ Check ladders stowed.

Electrical Checklist

Page

❑ Verify electrical hookups solid

❑ Check seed monitor terminal and observe

any diagnostic messages

a

❑ Configure monitor for crop and population

a

a.

Refer to DICKEY-john

®

Air Cart Control manual.

Hopper and Air System Checklist

Page

❑ Meter doors closed

46

❑ Manifold to hopper seal

❑ Materials loaded

❑ Hose routings - no sags, no pinches (check

wing-folded & field positions)

-

❑ Hoses fully connected to meters, towers

and openers

-

Frame Mounted Coulter Checklist

Page

❑ Coulter blade wear

❑ Coulter to row alignment

❑ Coulter down-force

Row Units Checklist

Page

❑ Preset depth handles alike.

❑ Preset down force springs alike, except in

tracks.

❑ Check wheel scraper gaps (if installed)

Hydraulic System Checklist

Page

❑ Check tractor hydraulic reservoir full

-

❑ Inspect connections for leaks

-

❑ Perform a raise and lower operation

❑ Set fan shut-off valve ON

58

❑ Check fan operation

Meters and Drive Checklist

Page

❑ Unused meter disabled by removing gear

❑ Correct DRIVER/DRIVEN rate Range

gears installed on meter(s) in use

❑ Correct optional flutes for rate Range

a

❑ Variable rate gearbox set per calibration

❑ Check contact tire inflation

❑ Check chain tension. Re-connect any

loose idler tensioning springs.

❑ Master Switch ON

(Variable Rate Kit option)

a.

Refer to Seed Rate manual.