Problem clean-outs, Hopper entry, Problem clean-outs hopper entry – Great Plains NTA2007HD Operator Manual User Manual

Page 114

110

Great Plains Manufacturing, Inc.

NTA607/2007HD

166-283M

04/04/2011

Problem Clean-Outs

For normal unloading of residual materials at completion

of planting, see “Unloading Materials” on page 108. For

normal clean-out of residue, see “Material Clean-Outs”

on page 109.

If, however, parking and storage recommendations have

not been followed, or material is defective, it is possible

to have hard-to-remove material present.

If the material fails to pass through the clean-out door,

take the following steps to remove it. Do not consider

entering the hopper until first completing these tasks.

Open the clean-out door.

Remove the strainer and evaluate the problem, for exam-

ple:

• If the problem is a single moveable large object, such

as a dead animal, fishing out from above may be the

solution.

• If the problem is congealed materials, scoop out a

sample from above and see if the mass dissolves in

water. If so, and there is a small amount of the material

involved, rinsing, or rinsing and pumping the hopper

from above may be the solution.

For small amounts of residual materials, poking with a

long pole may suffice to push it through the clean-out.

If poking doesn’t produce satisfactory results, and you

intend to try wash-out, poke at least one hole down to the

meter clean-out, so that water can flow out.

If wash-out is contemplated, start by introducing a small

amount of water, and make sure that it appears at the

clean-out within 15 minutes. If not, you will just be adding

water to the problem. The hopper is not designed to hold

water at full capacity. Add no more water.

Hopper Entry

Normal use of the hopper and routine maintenance do

not require entry.

The hopper vent tube structure includes features to aid

emergency egress. It is not intended for routine entry.

However, do not remove the vent tube structure, as it is

required for pressure-balancing the air space above the

material.

Depending on their use, the NTA607HD or NTA2007HD

material hoppers may be or become “permit-required

confined spaces” under U.S. OSHA regulations (29 CFR

1910.146) and similar regulations, statutes, insurance

agreements and local business policy. A written policy

and permitting process may be required for any hopper

entry.

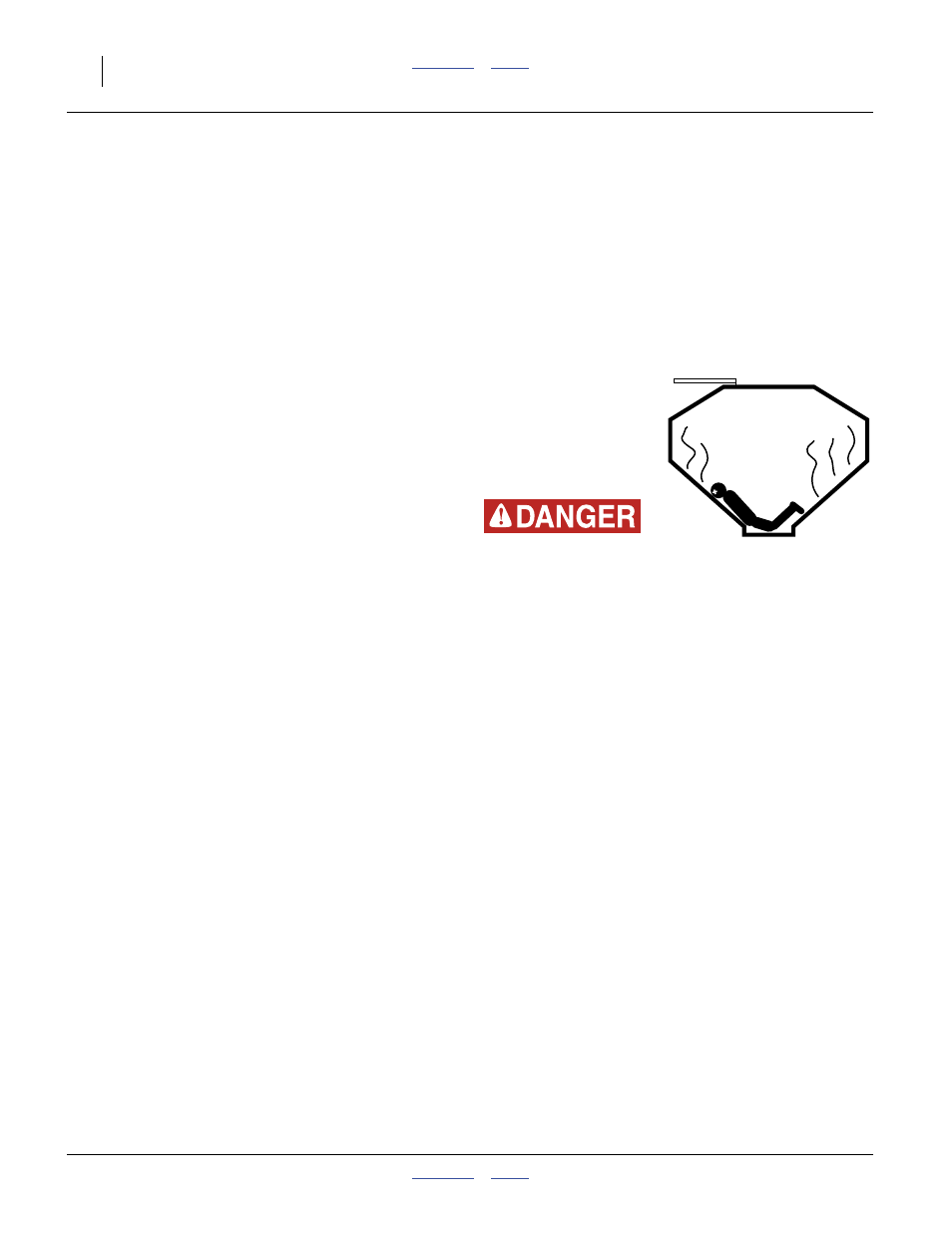

Rapid Suffocation Hazard:

Encrusted grain may be loose and flowing beneath the crust.

Any hollow spaces are highly likely to have insufficient oxygen

and/or toxic gases from microbial action. Falling through a

crust in either case can result in death in a matter of seconds.

Never enter a hopper to dislodge a crust or bridge.

▲ A hopper that is full or merely appears full can be an

entrapment hazard. You can sink entirely into the grain, or

into a void, and suffocate in a matter of seconds. Grain

bridges and crusts are especially dangerous.

▲ You can be overcome by hazardous fumes very quickly even

in an empty hopper with the lid open.

▲ A partially full hopper, even with no bridging present, is a

suffocation risk.

Oxygen levels may be insufficient and/or

dust levels may be too high for breathing.

▲ Do not enter a hopper for loading material.

▲ Do not enter a hopper for unloading material.

▲ Do not enter a hopper for routine cleaning.

▲ Do not enter a hopper for any meter maintenance.

▲ Never enter a hopper without at least one trained and

equipped attendant present.

▲ Never enter a hopper for any reason unless you fully com-

ply with applicable laws, regulations, rules, agreements,

and the instructions in this section. Where applicable laws,

regulations, rules, agreements contradict an instruction

below, do not follow that instruction.