Maintenance lift lock, Maintenance lift unlock – Great Plains NTA2007HD Operator Manual User Manual

Page 109

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

105

04/04/2011

166-283M

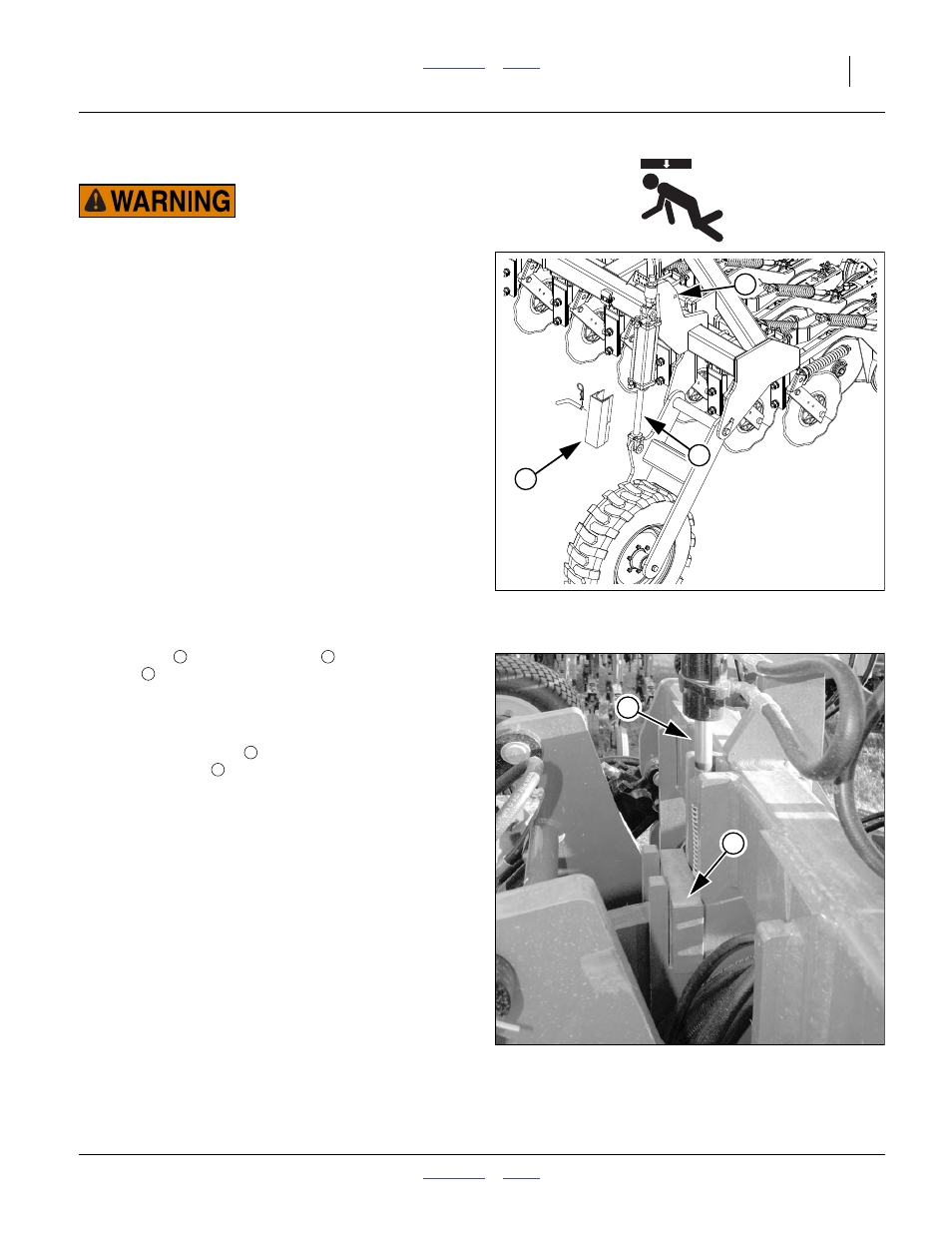

Maintenance Lift Lock

Crush and Pinch Hazards; Equipment Damage Risk:

Do not rely on hydraulics to hold the implement at lift. Use the

maintenance lift locks provided. Unlocked lift cylinders settle

over time. Implement sections can crush anyone working

under them. Implement links can pinch or crush anyone work-

ing near them.

Do not rely on the transport lift lock to hold the wings at

raised. Use the gauge wheel lock channels provided. Unlocked

gauge wheel cylinders settle over time. Outer wing openers

can crush anyone working under them. Openers at wing gaps

can pinch anyone working between them. Opener damage is

also possible.

Locks, including gauge wheel cylinder locks, are pro-

vided to hold all implement sections at raised for mainte-

nance, and for raised unfolded storage. The gauge wheel

lock channels are not used in routine operations (field or

transport).

Steps to engage maintenance lift lock presume a starting

configuration of implement unfolded and lowered:

1.

Raise the unfolded implement.

Refer to Figure 89

2.

Install the gauge wheel lock channels. Remove the

channels

from the wing lugs

and pin to cylinder

rods

.

With the implement still fully raised, begin a fold

operation (page 33) just long enough to cause the

center lock cylinder

to extend and engage the

center lock lug

.

4.

Lower the implement.

Maintenance Lift Unlock

1.

Raise the implement.

2.

Remove the gauge wheel lock channels. Return

them to storage.

3.

To lower, Perform an unfold operation (page 31) just

long enough to disengage the center lock.

To fold, leave the center lock engaged, and complete

a fold operation (page 33).

Null4:

Figure 89

Maintenance Lock Channel

31415

1

2

3

Null4:

Figure 90

Center Lock Engaged

31248

4

5

1

2

3

1

1