Fabricator 211i problems/service, 02 routine service and calibration requirements – Tweco 211i Fabricator User Manual

Page 84

FABRICATOR 211i

PROBLEMS/SERVICE

PROBLEMS AND ROUTINE SERVICE

5-2

Manual 0-5157

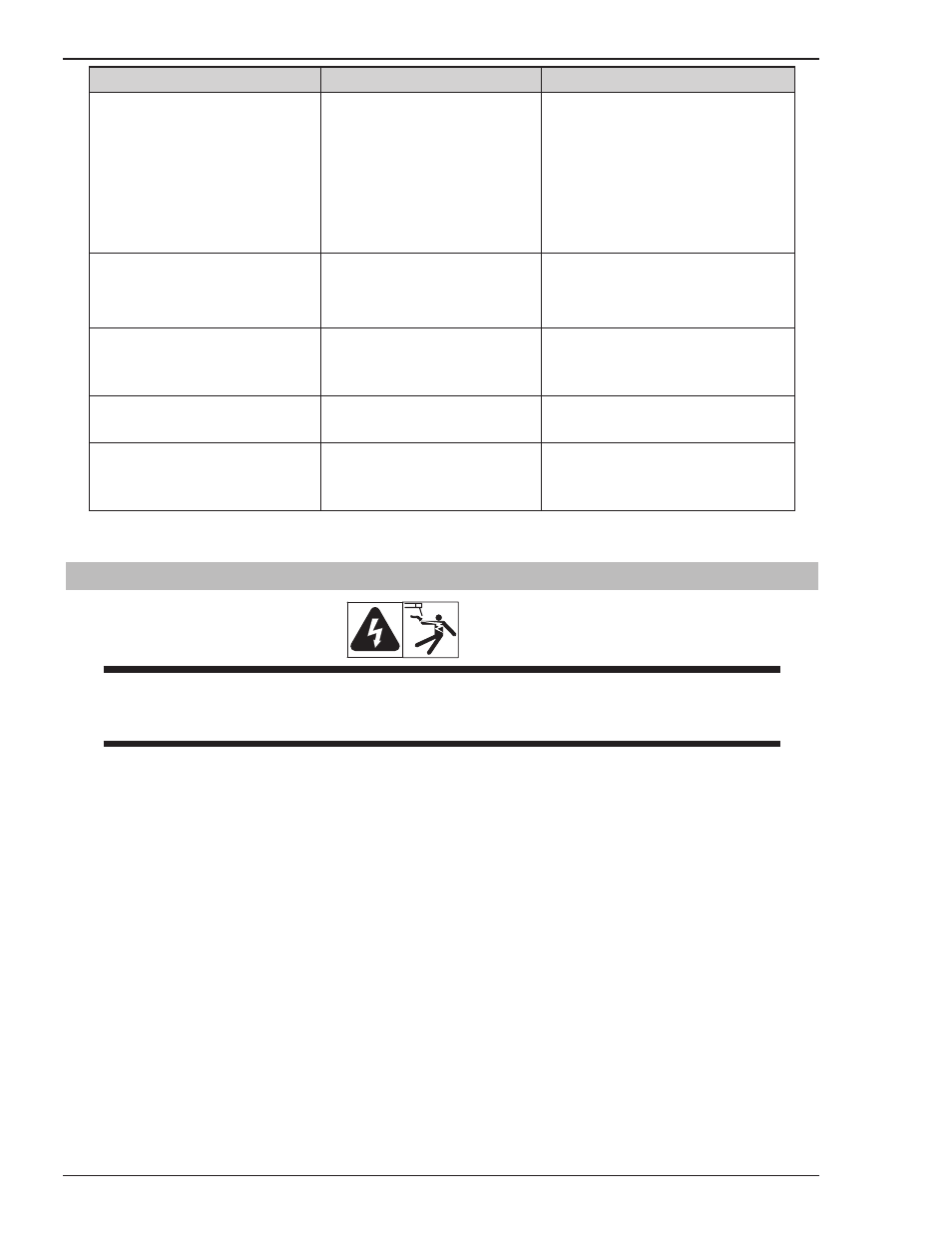

FAULT

CAUSE

REMEDY

7 No gas flow in MIG mode.

A Gas hose is damaged.

A Replace or repair.

B Gas passage contains

impurities.

B Disconnect gas hose from the

rear of power source and blow

out impurities.

C Gas regulator turned OFF.

C Turn ON regulator.

D Empty gas cylinder.

D Replace gas cylinder.

8 Gas flow continues after

the trigger switch has been

released (MIG mode).

Gas valve has jammed open

due to impurities in the gas

or the gas line.

Have an accredited Tweco ser-

vice provider repair or replace

gas valve.

9 Power indicator will not

illuminate and welding arc

cannot be established.

The Electricity Supply has

exceeded voltage limits of

the power source.

Ensure that the Electricity Sup-

ply is within 115V ± 10% or

208/230VAC ± 10%.

10 TIG electrode melts when

arc is struck.

TIG torch is connected to

the (+) VE terminal.

Connect the TIG torch to the (-)

VE terminal.

11 Arc flutters during TIG

welding.

Tungsten electrode is too

large for the welding cur-

rent.

Select the correct size of tung-

sten electrode. Refer to Table

4-7.

Table 5-1: Power Source Problems

5.02 Routine Service and Calibration Requirements

WARNING

There are extremely dangerous voltage and power levels present inside this Inverter Power Source.

Do not attempt to open or repair unless you are an accredited Tweco Service Provider. Disconnect the

Welding Power Source from the Electricity Supply before disassembling.

Routine Inspection, Testing & Maintenance

The inspection and testing of the power source and associated accessories shall be carried out by a licensed

electrician. This includes an insulation resistance test and an earthing test to ensure the integrity of the unit is

compliant with Tweco's original specifications.

A. Testing Schedule

1. For transportable equipment, at least once every 3 months; and

2. For fixed equipment, at least once every 12 months.

The owners of the equipment shall keep a suitable record of the periodic tests and a system of tagging, includ-

ing the date of the most recent inspection.

A transportable power source is deemed to be any equipment that is not permanently connected and fixed in

the position in which it is operated.

B. Insulation Resistance

Minimum insulation resistance for in-service Tweco Inverter Power Sources shall be measured at a voltage

of 500V between the parts referred to in Table 5-2 below. Power sources that do not meet the insulation

resistance requirements set out below shall be withdrawn from service and not returned until repairs have

been performed such that the requirements outlined below are met.