Basic welding fabricator 211i – Tweco 211i Fabricator User Manual

Page 67

BASIC WELDING

FABRICATOR 211i

Manual 0-5157

4-7

BASIC WELDING

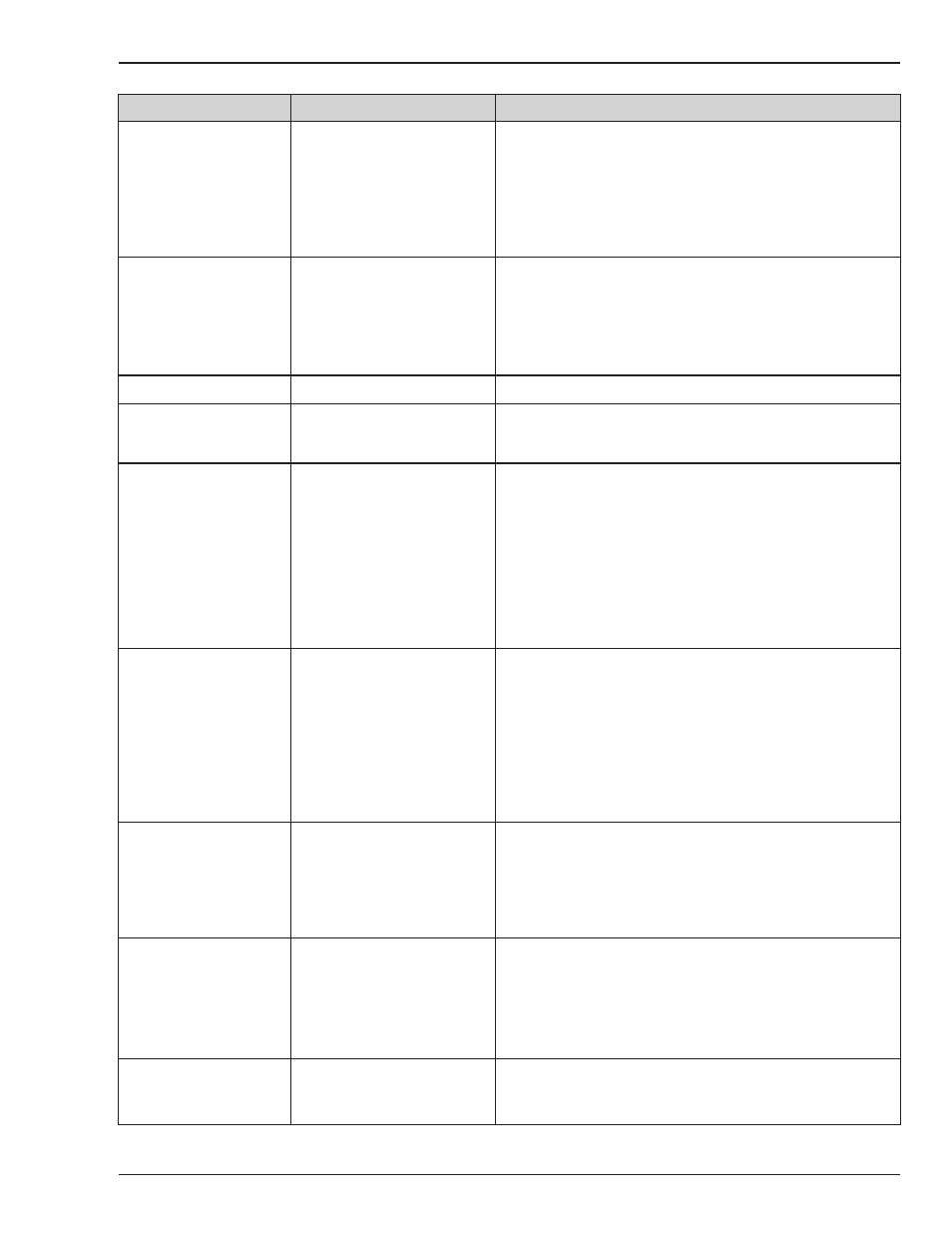

Basic MIG (GMAW/FCAW) Welding Troubleshooting

FAULT

CAUSE

REMEDY

1 Undercut

A Welding arc voltage too

high.

A Decrease voltage or increase the wire feed speed.

B Incorrect MIG Gun angle

B Adjust angle.

C Excessive heat input

C Increase the MIG Gun travel speed and/or decrease welding

current by decreasing the voltage or decreasing the wire feed

speed.

2 Lack of penetration

A Welding current too low

A Increase welding current by increasing wire feed speed and

increasing voltage.

B Joint preparation too narrow

or gap too tight

B Increase joint angle or gap.

C Shielding gas incorrect

C Change to a gas which gives higher penetration.

3 Lack of fusion

Voltage too low

Increase voltage.

4 Excessive spatter

A Voltage too high

A Decrease voltage or increase the wirespeed control.

B Voltage too low

B Increase the voltage or decrease wirespeed.

5 Irregular weld shape

A Incorrect voltage and

current settings. Convex,

voltage too low. Concave,

voltage too high.

A Adjust voltage and current by adjusting the voltage control

and the wirespeed control.

B Wire is wandering.

B Replace Velocity contact tip.

C Incorrect shielding gas

C Check shielding gas.

D Insufficient or excessive

heat input

D Adjust the wirespeed control or the voltage control.

6 Weld cracking

A Weld beads too small

A Decrease travel speed

B Weld penetration narrow

and deep

B Reduce current and voltage and increase MIG Gun travel

speed or select a lower penetration shielding gas.

C Excessive weld stresses

C Increase weld metal strength or revise design

D Excessive voltage

D Decrease voltage.

E Cooling rate too fast

E Slow the cooling rate by preheating part to be welded or cool

slowly.

7 Cold weld puddle

A Loose welding cable con-

nection.

A Check all welding cable connections.

B Low primary voltage

B Contact supply authority.

C Fault in power source

C Have an Accredited Tweco Service Provider test then replace

the faulty component.

8 Arc does not have a

crisp sound that short

arc exhibits when the

wirefeed speed and

voltage are adjusted

correctly

The MIG Gun has been con-

nected to the wrong voltage

polarity on the front panel.

Connect the MIG Polarity Cable to the positive (+) welding

terminal for solid wires and gas shielded flux cored wires.

Refer to the electrode wire manufacturer for the correct

polarity.

9 Poor weld result from

setup chart parameters

Contact tip has arc marks in

the bore causing excessive

drag on the wire.

Replace the contact tip with only a Genuine Tweco Velocity

contact tip.

Table 4-4: MIG (GMAW /FCAW) Welding Problems