Installation/setup fabricator 211i, 16 feed roller pressure adjustment, 17 changing the feed roll – Tweco 211i Fabricator User Manual

Page 53

INSTALLATION/SETUP

FABRICATOR 211i

Manual 0-5157

3-21 INSTALLATION/SETUP

3.16 Feed Roller Pressure Adjustment

The pressure (top) roller applies pressure to the grooved feed roller via an adjustable pressure screw. These devices

should be adjusted to a minimum pressure that will provide satisfactory WIREFEED without slippage. If slipping oc-

curs, and inspection of the wire contact tip reveals no wear, distortion or burn back jam, the conduit liner should be

checked for kinks and clogging by metal flakes and swarf. If it is not the cause of slipping, the feed roll pressure can

be increased by rotating the pressure screw clockwise.

WARNING

Before changing the feed roller ensure that the Electricity Supply to the power source is switched OFF.

CAUTION

The use of excessive pressure may cause rapid wear of the feed rollers, shafts and bearing.

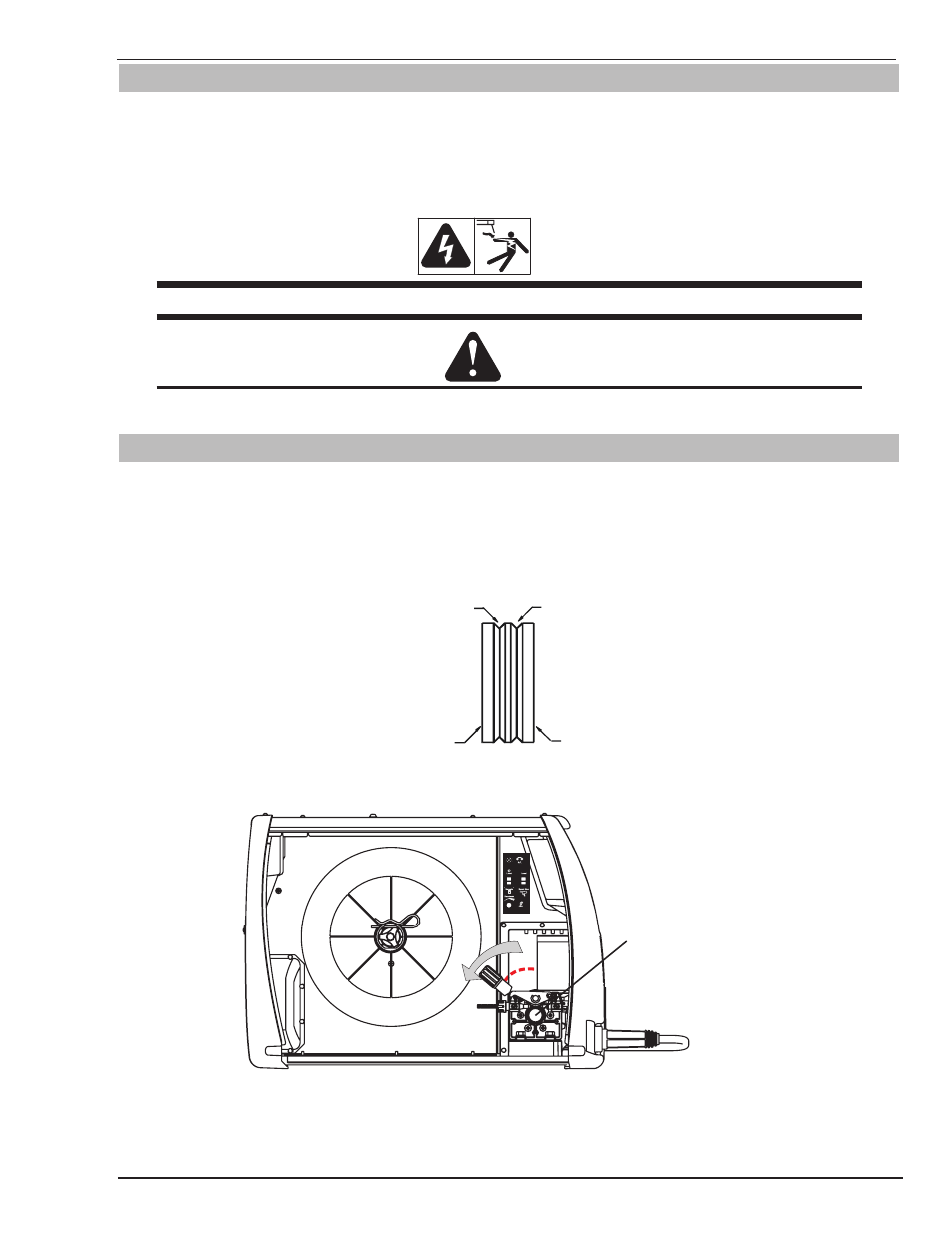

3.17 Changing the Feed Roll

To change feed roll remove the feed roll retaining screw by turning in an anti-clockwise direction. Once the feed roll

is removed then to replace feed roll simply reverse these directions. Note: Be sure not to lose key that is located on

Drive Motor Shaft. This key must align with drive roll groove for proper operation.

A dual groove feed roller is supplied as standard. It can accommodate 0.6/0.8mm diameter hard wires. Select the

roller required with the chosen wire size marking facing outward.

GROOVE “B”

GROOVE “A”

GROOVE “A” SIZE

GROOVE “B” SIZE

A-09583

Figure 3-16: Dual Groove Feed Roller

Feed Roll Retaining Screw

Art # A-10428

Figure 3-17: Changing the Feed Roll