Basic welding fabricator 211i – Tweco 211i Fabricator User Manual

Page 73

BASIC WELDING

FABRICATOR 211i

Manual 0-5157

4-13

BASIC WELDING

Art # A-07702

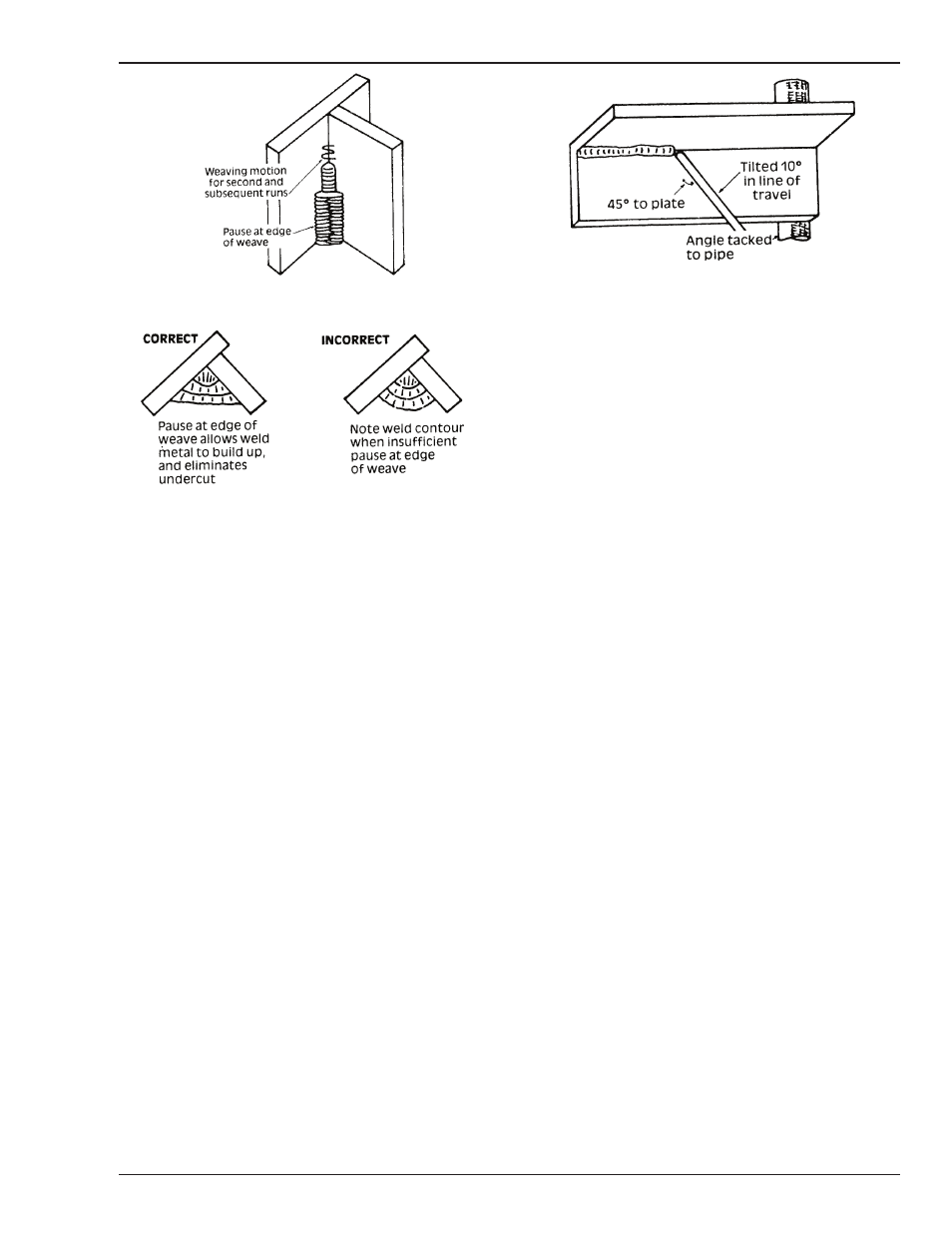

Figure 4-26: Multi Run Vertical Fillet Weld

Art # A-07703

Figure 4-27: Examples of Vertical Fillet Welds

2. Vertical Down

The E7014 electrode makes welding in this

position particularly easy. Use a 1/8" (3.2 mm)

electrode at 100 amps. The tip of the electrode is

held in light contact with the work and the speed

of downward travel is regulated so that the tip of

the electrode just keeps ahead of the slag. The

electrode should point upwards at an angle of

about 45º.

3. Overhead Welds

Apart from the rather awkward position necessary,

overhead welding is not much more difficult that

downhand welding. Set up a specimen for over-

head welding by first tacking a length of angle

iron at right angles to another piece of angle iron

or a length of waste pipe. Then tack this to the

work bench or hold in a vice so that the specimen

is positioned in the overhead position as shown

in the sketch. The electrode is held at 45º to

the horizontal and tilted 10º in the line of travel

(Figure 4-28). The tip of the electrode may be

touched lightly on the metal, which helps to give

a steady run. A weave technique is not advisable

for overhead fillet welds. Use a 1/8" (3.2 mm)

E6013 electrode at 100 amps, and deposit the

first run by simply drawing the electrode along at

a steady rate. You will notice that the weld deposit

is rather convex, due to the effect of gravity before

the metal freezes.

Art # A-07704

Figure 4-28: Overhead Fillet Weld

Distortion

Distortion in some degree is present in all forms of

welding. In many cases it is so small that it is barely

perceptible, but in other cases allowance has to be made

before welding commences for the distortion that will

subsequently occur. The study of distortion is so complex

that only a brief outline can be attempted hear.

The Cause of Distortion

Distortion is caused by:

A. Contraction of Weld Metal:

Molten steel shrinks approximately 11 per cent in

volume on cooling to room temperature. This means

that a cube of molten metal would contract approxi-

mately 2.2 per cent in each of its three dimensions.

In a welded joint, the metal becomes attached to the

side of the joint and cannot contract freely. Therefore,

cooling causes the weld metal to flow plastically, that

is, the weld itself has to stretch if it is to overcome the

effect of shrinking volume and still be attached to the

edge of the joint. If the restraint is very great, as, for

example, in a heavy section of plate, the weld metal

may crack. Even in cases where the weld metal does

not crack, there will still remain stresses "Locked-up"

in the structure. If the joint material is relatively weak,

for example, a butt joint in 5/64" (2.0 mm) sheet,

the contracting weld metal may cause the sheet to

become distorted.