Tweco 400 Ultra-Cut(October 2014) User Manual

Page 82

ULTRA-CUT 100 XT/200 XT/300 XT/400 XT

4-18

OPERATION

Manual 0-5264

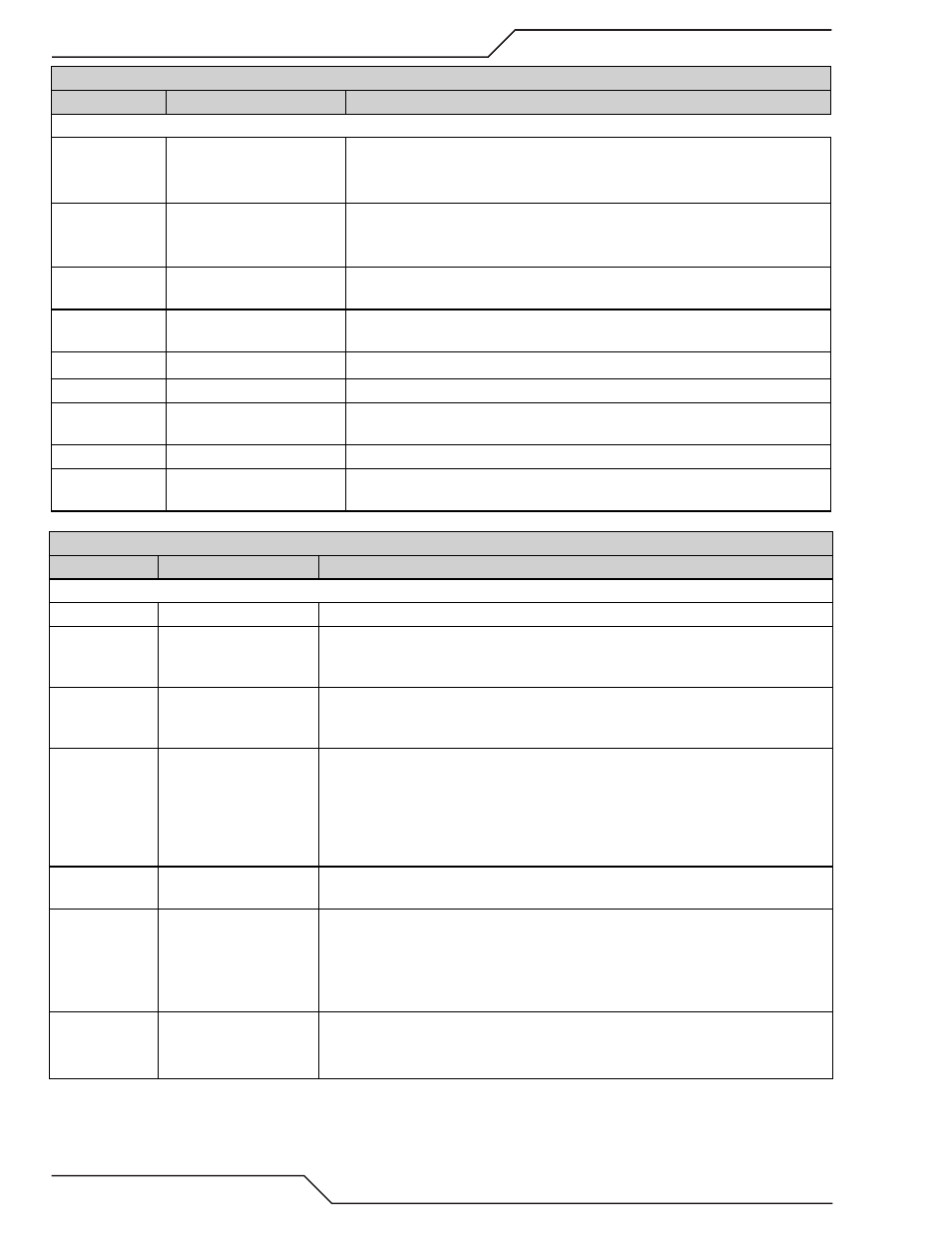

CCM Status Code

Code

Message

Remedy / Comments

Group 3 -- Gas Controller Status & Protocol

301

Gas control communication

fault

Problem with fiber optic cable to GCM 2010; Dirt on fiber ends or in connec-

tors; blow out with clean dry air. Fiber not locked into connector; Sharp bends

in fiber cable; Fiber defective; GCM 2010 circuit board defect;

302

Gas Control reply fault

Problem with fiber optic cable to GCM 2010; Dirt on fiber ends or in connec-

tors; blow out with clean dry air. Fiber not locked into connector; Sharp bends

in fiber cable; Fiber defective; GCM 2010 circuit board defect;

303

Gas Supply Pressure out of

range.

GCM 2010 inlet plasma or shield pressure low or defective pressure sensors

PS3 & PS4; Defective GCM 2010 PCB.

304

Gas Control Purging

Normal following power up or returning from Plasma Disable. Wait for purge

to finish.

305

Gas Control protocol error

Verify Firmware revision for compatibility with GCM 2010

306

Not used

Reserved for other future use.

307

Gas Control sequencing

error

Verify Firmware revision for compatibility with GCM 2010

308

Gas Control Type Mismatch

Wrong CCM (Auto-Cut or Pak 200 type?) for Ultra-Cut; Install correct CCM

309

Gas Control command fault

Verify Firmware revision for compatibility with GCM 2010; Electromagnetic

interference with Arc Starter; inspect grounding; bonding; and isolation

CCM Status Code

Code

Message

Remedy / Comments

Group 4 -- Torch Coolant System

401

Coolant Level low

Check coolant level, add as needed. Defective or disconnected level sensor.

402

Low coolant flow

Coolant flow as measured by flow switch FS1 is less than 0.7 gpm; Clogged filter;

Restriction in torch lead or head; Wrong style consumables; broken or defective

torch coolant tube/check valve; Defective pump or bypass valve.

403

Coolant overheated

Coolant supply temperature exceeded 75 degrees Celcius (167F). Operating with

side panel loose or removed; Air flow blocked at air inlet or exit of power supply;

Coolant fan failed; radiator fins clogged with dirt.

404

Coolant System not

ready.

Proper coolant flow of 0.7 gpm as measured by flow switch FS1 was not obtained

during up to 4 minutes of Priming. New installation can require additional Priming

cycle(s) to fill hoses with coolant; cylce power to restart Priming; Coolant hoses

or torch hoses reversed; Clogged coolant filter; Restriction in torch lead or head;

Wrong style consumables; broken or defective torch coolant tube/check valve;

Defective or disconnected FS1 flow SW; Defective pump or bypass valve.

405

Low Coolant Level Warn-

ing

Low coolant level during cut, does not stop cut.

Add coolant as required.

406

Coolant Flow Low Warn-

ing.

This is a warning, does not stop system operation. Coolant flow rate lower than ex-

pected. Can be caused by gas bubbles being introduced into the coolant or wrong or

mismatched or worn consumable parts; Failed seals in torch cartridge or torch body;

Clogged coolant filter; Restriction in torch lead or head; defective or disconnected

FL1 flow sensor.

407

Coolant overheated, high

ambient.

Coolant supply temperature exceeded 75 degrees Celsius (167 Fahrenheit) likely

cause ambient greater than 40 degrees Celsius (104 Fahrenheit); Reduce cutting

duty cycle; Reduce ambient temperature; Add separate coolant cooler.

No Group 5 (500) status codes with GCM 2010 system.