11 connect coolant leads, Connect coolant leads -10 – Tweco 400 Ultra-Cut(October 2014) User Manual

Page 36

ULTRA-CUT 100 XT/200 XT/300 XT/400 XT

3-10

INSTALLATION

Manual 0-5264

5. Increasing the ground rod length beyond 20 - 30 ft (6.1 – 9.1 m) does not generally increase the effectiveness

of the ground rod. A larger diameter rod which has more surface area may help. Sometimes keeping the soil

around the ground rod moist by continuously running a small amount of water into it will work. Adding salt

to the soil by soaking it in salt water may also reduce its resistance. You may also try a chemical ground rod

devise. When these methods are used, periodic checking of the ground resistance is required to make sure the

ground is still good.

E. Routing Of Torch Leads

1. To minimize RF interference, position torch leads as far as possible from any CNC components, drive motors,

control cables, or primary power lines. If cables have to pass over torch leads, do so at an angle. Do not run the

plasma control or other control cables in parallel with the torch leads in power tracts.

2. Keep torch leads clean. Dirt and metal particles bleed off energy, which causes difficult starting and increased

chance of RF interference.

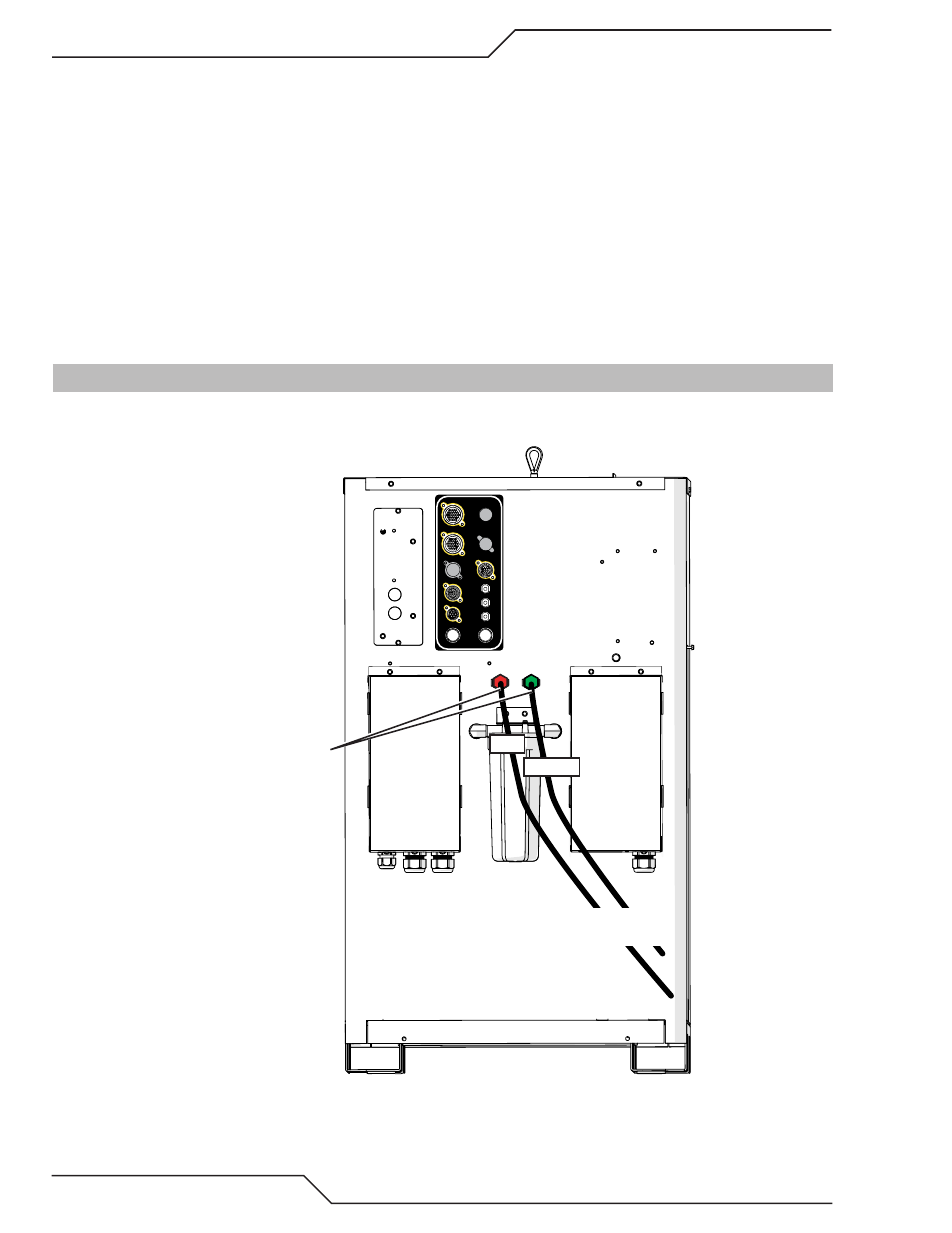

3.11 Connect Coolant Leads

1. Connect the color-coded coolant hoses to the coolant connections on the power supply rear panel. The sup-

ply line (out) is flagged green, the return line (in) is flagged red.

COOLANT

RETURN SUPPLY

Coolant Connections

RED

GREEN

To RAS 1000 Arc Starter or

HE-400 Heat Exchanger if used

Art # A-11534_AB

USER INPUT

HEIGHT CONTROL

F1 - 8A SB 230 VAC

F2 - 8A SB 230 VAC

CB4 - 5A 120 VAC

CB3 - 5A 24 VAC

CB2 - 5A 120 VAC

J55 - GCM

J15 - CNC

J59 - RAS

J70 - HE

J54 - TSC /COMM