Tweco 15XC CE Merlin PAK User Manual

Page 57

Manual 0-2529

3 - 23

OPERATION

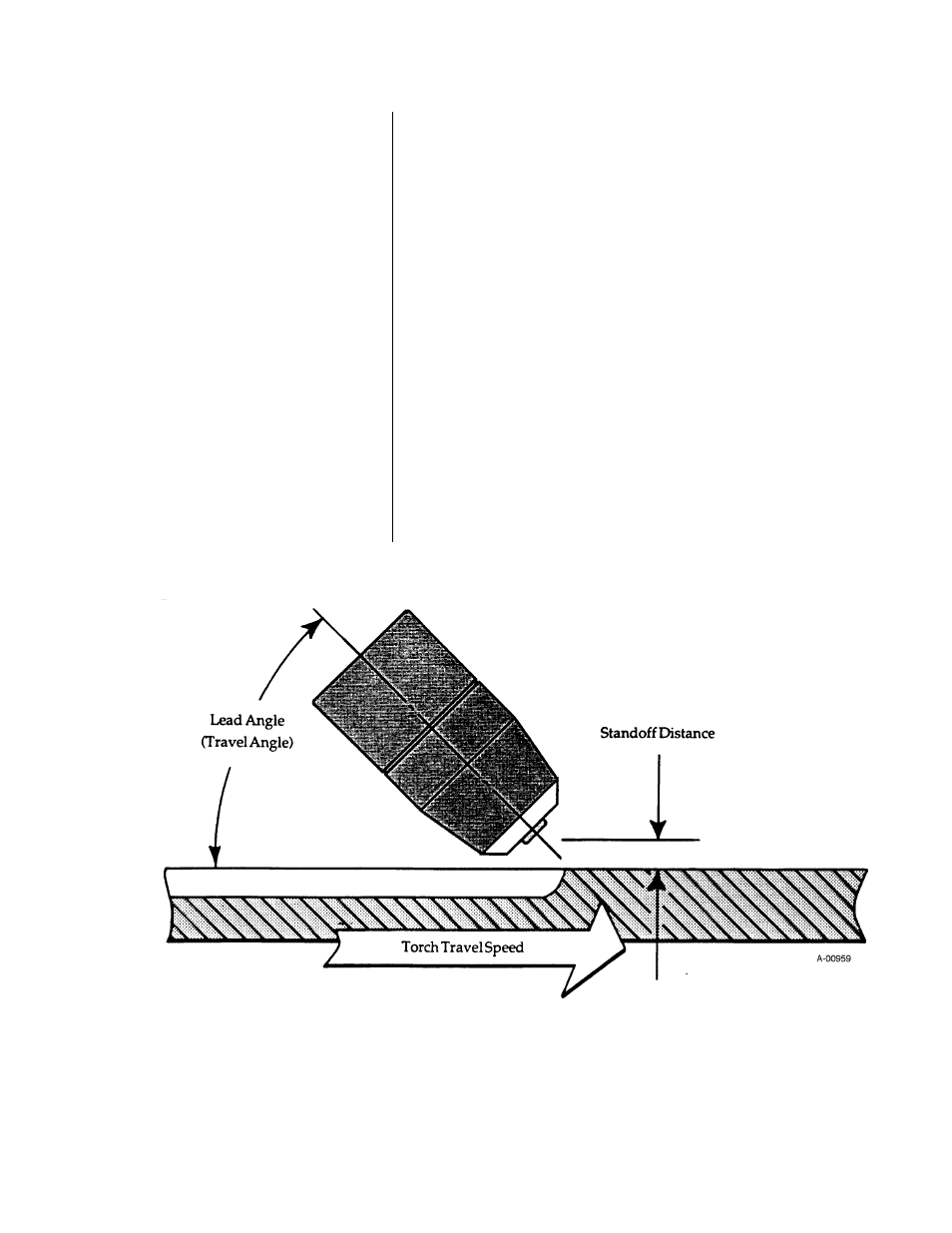

Gouging performance depends on the torch travel speed,

the current level, the angle at which the torch is held to the

workpiece (lead angle), and the distance between the torch

tip and the workpiece (standoff). Gouging can be accom-

plished with either a hand or machine torch.

Optimum torch travel speed for gouging is between 20

and 120 inches per minute (0.5 and 3.0 meters per minute).

Travel speed is dependent on current setting, lead angle,

mode of operation (hand or machine torch), and desired

results.

Current settings depend on torch travel speed, the mode

of operation (hand or machine torch), and the amount of

material to be removed.

The angle at which the torch is held depends on the

current setting and the torch travel speed. The recom-

mended lead angle is 20-25°. An angle greater than 25°

may result in inconsistent metal removal, blowback of

slag, and contaminated gouges. If the lead angle is too

small (less than 20°), less material may be removed, re-

quiring more passes. In some applications, such as remov-

ing welds or working with light metal, this may be desir-

Gouging Parameters

Torch Travel Speed

Figure 3-M Gouging Parameters

Current Setting

Lead Angle

(Travel Angle)