7 machine torch operation, 7 machine torch operation -18 – Tweco 15XC CE Merlin PAK User Manual

Page 52

OPERATION

3 - 18

Manual 0-2529

3.7 MACHINE TORCH OPERATION

Cutting with a

Machine Torch

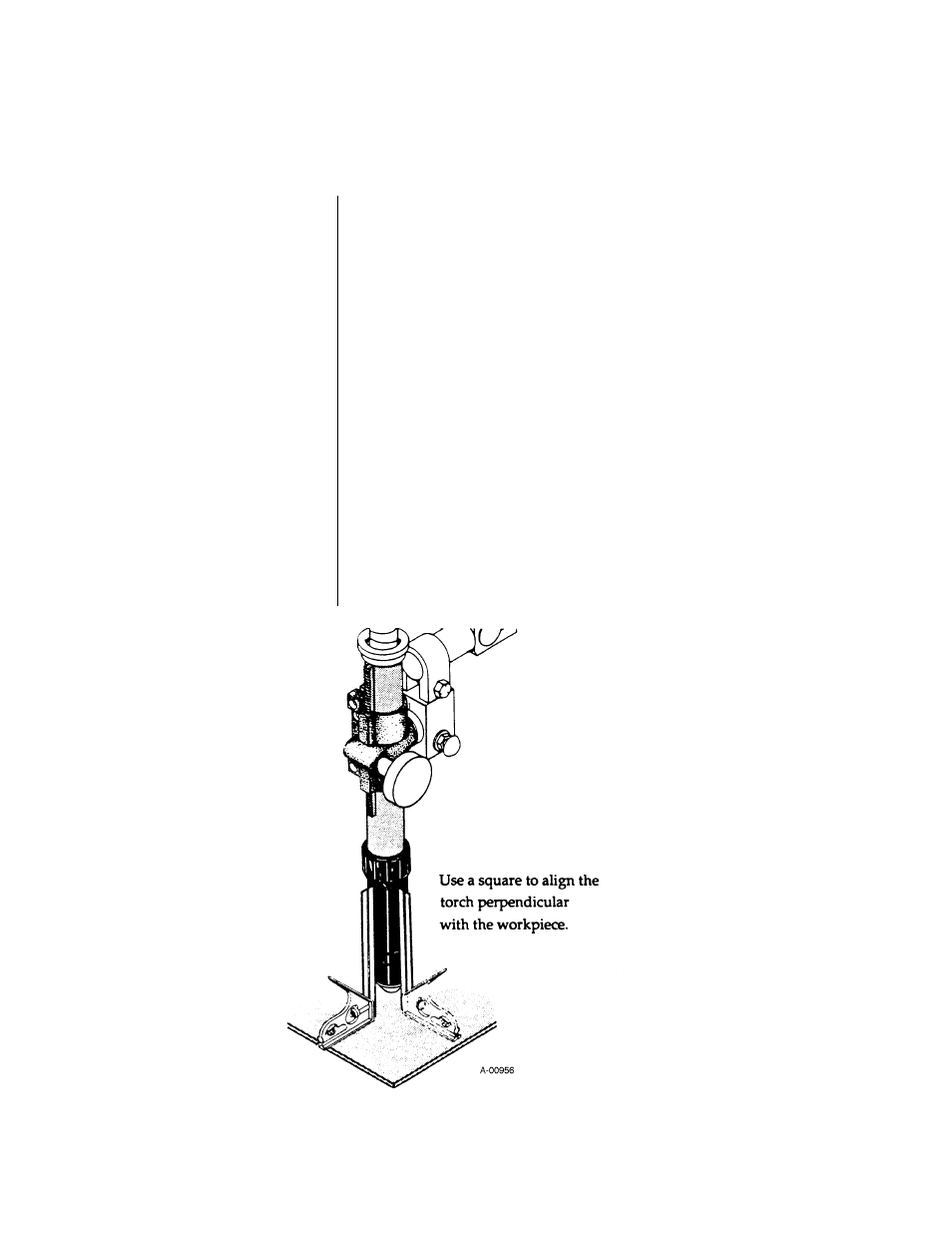

1. A machine torch should be aligned perpendicular to

the surface of the workpiece to obtain a clean, vertical

cut. Use a square to align the torch (see Figure 3-I).

2. Position the center of the torch over the edge of the

workpiece where the cut is to start. The transferred

cutting arc will then be established at the plate edge

when the torch is activated.

3. The machine torch can be activated by the remote

operator control panel, remote control pendant, or by

remote interface device such as CNC. After a two

second gas purge, the pilot arc will start. The pilot arc

will stay on as long as the torch is activated.

4. With the pilot arc on the main cutting arc is established

as soon as the torch is brought within 1/8 - 3/8 in (3 -

10 mm) of the workpiece. If the cutting arc is inter-

rupted and the torch is still activated, as when cutting

expanded metal, the pilot arc will automatically restart

(see Auto-Restart Options, page 3-13). De-activating

the torch will shut off either the pilot or main arc

(depending on the mode of operation).

Figure 3-I Machine Torch Set-up