tekmar 275 Boiler Control User Manual

Page 8

©

2012 275_D

-

11/12

8

of

48

Modulating Boilers

Section D

The 275 can operate up to four modulating boilers. The

control also provides dry contacts for either burner ignition

or boiler pump. Selection is made through Boiler Relay

setting in the Adjust menu.

Once a boiler is required to operate, the control outputs

an analog signal corresponding to the Start Modulation

setting and then turns on the boiler relay. Once the Fire

Delay time has elapsed, the modulating output is adjusted

to the Minimum Modulation setting. The control then holds

the modulating output at Minimum Modulation until the

Minimum Modulation Delay time has elapsed. Proportional,

Integral and Derivative (PID) logic is used in order to satisfy

the boiler target temperature.

Modulation Mode Setting in Adjust Menu

The control includes a Modulation Mode setting that

selects either Sequential or Parallel Modulation. Sequential

modulation should be used on boilers that are more efficient

when operating at high fire. Parallel modulation should be

used on boilers that are more efficient when operating at

low fire.

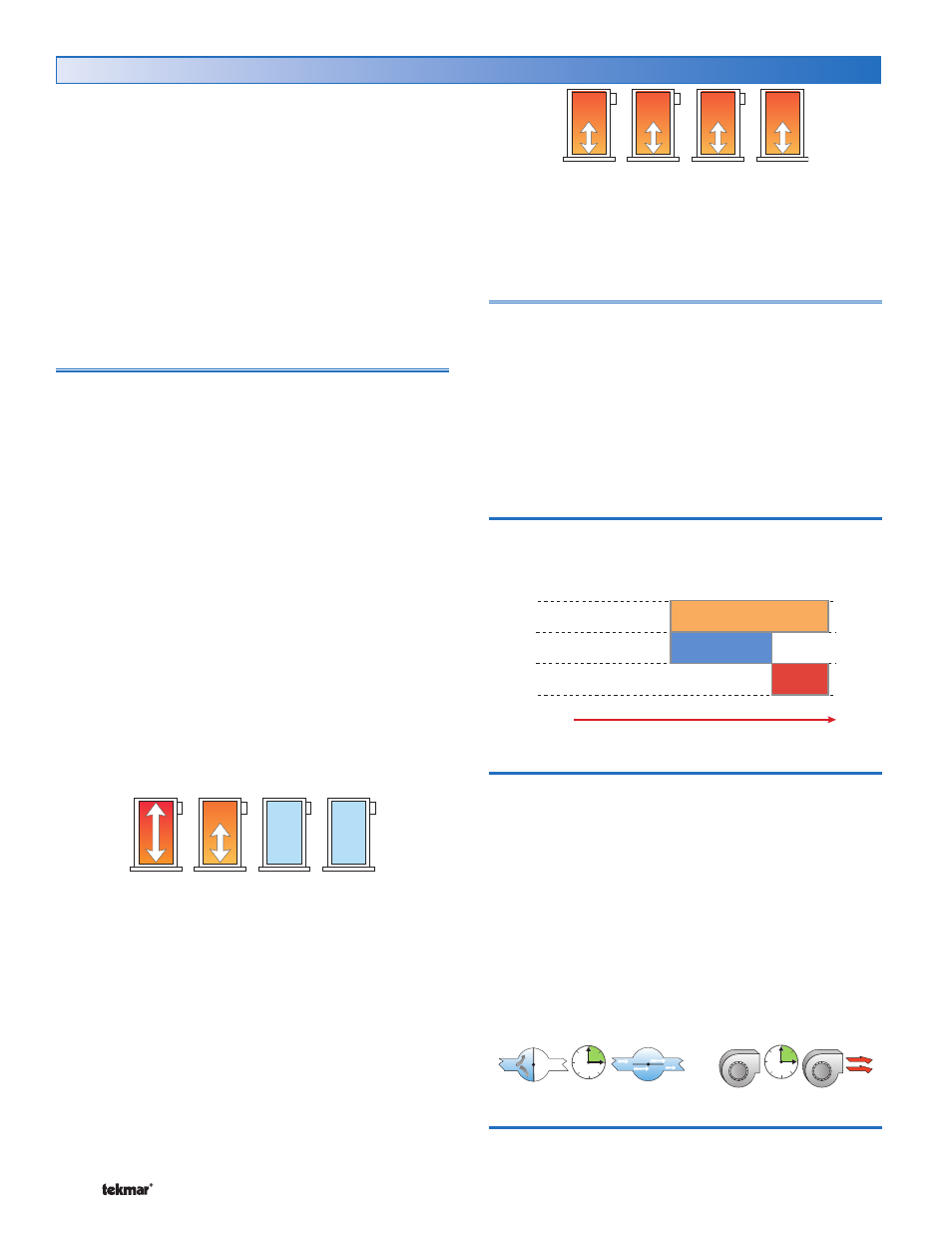

Sequential Modulation

In sequential modulation, the first boiler is turned on and

is modulated to satisfy light loads. Once the first boiler

does not have enough capacity to satisfy the load, the first

boiler reduces its modulation to provide a smooth transition

when the second boiler fires at low fire. The first boiler

then modulates up to maximum modulation as the load

increases. Only then is the second boiler able to increase

its output as the load continues to increase. When the third

boiler is required, the second boiler reduces its modulation

to allow the third boiler to operate at low fire. As the load

continues to increase, the second boiler is modulated to

its maximum and then the third boiler is modulated. The

operation is reversed when shutting off the boilers.

100%

60%

Off

Off

Parallel Modulation

In parallel modulation, the first boiler turns on at low fire

and begins to increase its modulation. Once the first boiler’s

output is greater than the combined output of the first and

second boiler’s low fire, the first boiler is modulated down

to low fire and the second boiler is fired at low fire. The

two boilers now modulate together. Once the two boiler’s

combined output is greater than the combined output of

all three boilers operating at low fire, the first and second

boilers are modulated down to low fire, and all three boilers

are operated at low fire. The boilers are then modulated

as the load increases. The operation is reversed when

shutting off the boilers.

40%

40%

40%

40%

The 275 is restricted to sequential staging if:

1. 1 or more boilers are configured to be On/Off.

2. Condensing mode is selected.

3. The plant is configured for direct DHW.

Boiler Start Modulation Setting in Adjust Menu

(per boiler)

The Start Modulation setting is the lowest modulation

output required to obtain proper ignition. Whenever boiler

operation is required, the control outputs an analog signal

corresponding to the Start Modulation setting and closes

the boiler contact to turn on the burner. After the Fire Delay

has elapsed and the burner is ignited, the control modulates

the firing rate between the Minimum Modulation setting and

the Maximum Modulation setting.

Boiler Fire Delay Setting in Adjust Menu

(per boiler)

The Boiler Fire Delay sets the time it takes for the boiler to

generate flame from the time the boiler turns on.

Boiler Contact Closed

Time

Fire Delay

Burner On

Boiler Motor Speed Setting in Adjust Menu

(per boiler)

The Motor Speed is the amount of time the boiler requires

to go from 0% modulation to 100% modulation.

Gas valve actuating motors have a design time from

fully closed to fully opened which can be found in the

manufacturer’s manual. The Motor Speed should be set

to this time.

The Motor Speed setting for a Variable Frequency Drive

(VFD) is the amount of time required to go from a stopped

position to 100% fan speed. Since a VFD has a very quick

response rate, it may be necessary to increase the Motor

Speed setting in order to increase the stability of the boiler

modulation.

OR

Boiler % Modulation in View Menu

View the current % modulation of each boiler in the View

menu.