tekmar 275 Boiler Control User Manual

Installation & operation manual, 275_d, Boiler control 275

Boiler Control 275

275_D

11/12

Replaces: 01/12

Installation & Operation Manual

Multi-Staging

1

of

48

©

2012 275_D

-

11/12

The Boiler Control 275 is designed to stage up to four condensing or non-condensing, modulating or on-off boilers using

P.I.D. staging to accurately maintain temperature. The control supports hybrid boiler plants that contain both condensing

and non-condensing boiler groups. Water temperature is controlled by outdoor reset for space heating applications or a

fixed setpoint for Domestic Hot Water (DHW) tank heating or industrial process heating applications. The control will also

accept an analog signal from an Energy Management System (EMS) to control the water temperature. Boiler equal run-time

rotation, pump exercising and stand-by system pump operation increase boiler plant reliability. The control is tekmarNet

®

communication compatible allowing for internet connectivity using an optional Gateway 483.

tN4 Compatible

BTC I Compatible

24 Hour, 5-11, 5-2, 7 Day Schedule

Flow or Combustion Air Proof

Four Modulating or On/Off Boilers

•

•

•

•

•

Equal Run Time Rotation

Primary Pump Sequencing

DHW Operation

Optional DHW Sensor

Setpoint Operation

•

•

•

•

•

Additional functions include:

Setback

Boiler Control 275

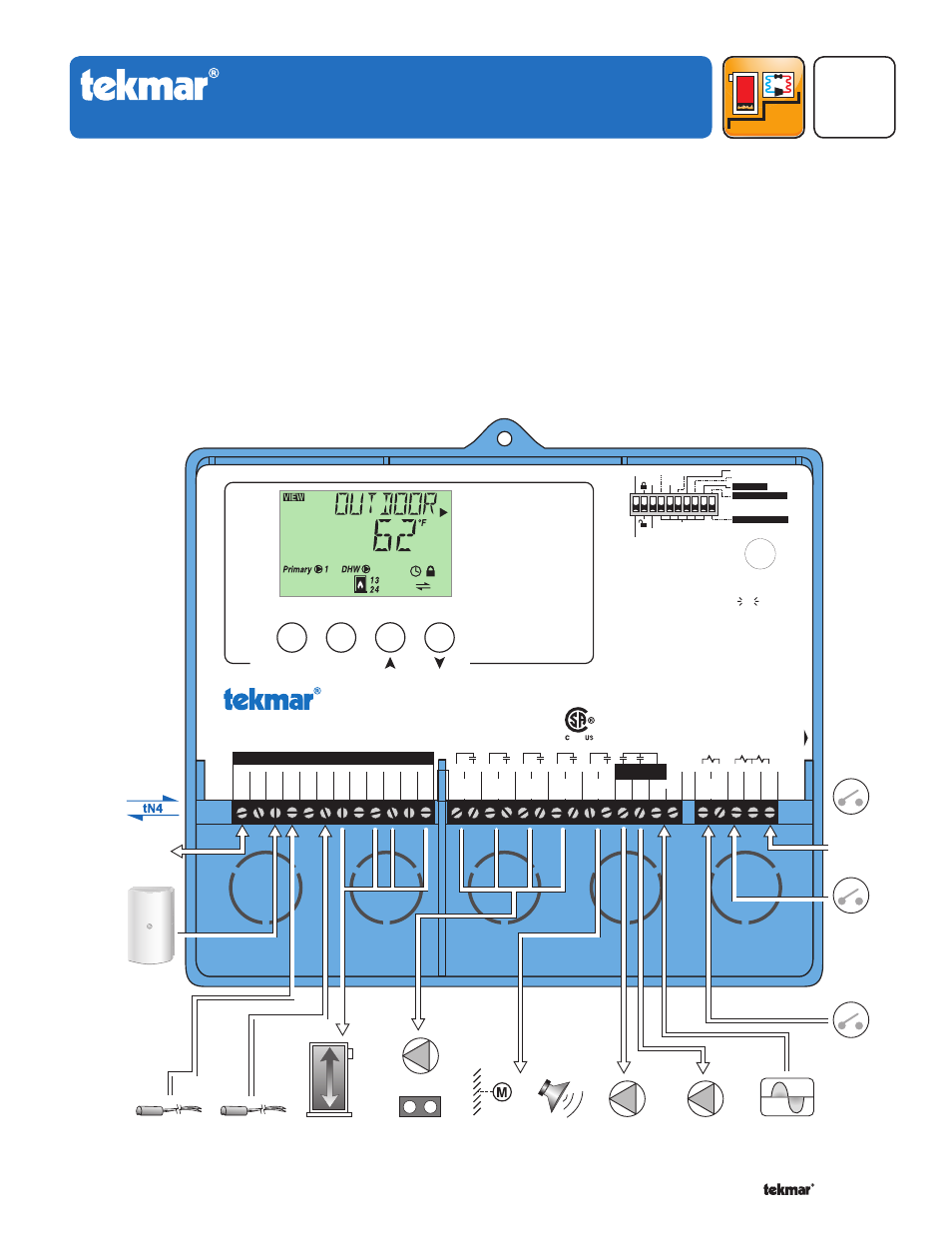

One tN4, Four Modulating Boiler & DHW / Setpoint

Menu

Item

Test

Boiler Demand

DHW / Setpoint Demand

Proof Demand

EMS Input Signal

Priority Override

Power

115 V ±10% 60 Hz 7 VA, 1150 VA max.

Relays

230 V (ac) 5 A 1/3 hp

Demands 20 to 260 V (ac) 2 VA

Designed and assembled in Canada by

tekmar Control Systems Ltd

tektra 1020-01

Meets Class B:

Canadian ICES

FCC Part 15

For maximum heat,

press and hold Test

button for 3 seconds.

not testing

testing

testing paused

off

red

red

BTC I

Off

EMS

Rotate

Fixed Last

Pump Sequencer

Exercise

Off

Demands

Dat

e Code

H2048B

Signal wiring must be rated at least 300 V.

DHW

29

/Setp

Com

30

Dem

Pr.

31

Dem

2

–

5

–

Mod1

1

+

Mod2

3

+

–

+

Mod3

4

+

Mod4

6

+

BRet/

7

Com

8

tN4

12

Boil

9

Out

10

Com

11

Prim

P1

L

N

26

Power

28

27

14

13

Do not apply power

24

DHW

/ P2

23

25

16

15

18

17

20

19

22

21

Fixed Lead

First On / Last Off

First On / First Off

Relay

1

Relay

2

Relay

3

Relay

4

C.A. /

Alert

Boiler

Demand

Sup

DHW

Zone Load Shedding

Input

Universal

Sensor

Included

Input

Universal

Sensor

Included

tN4

Boiler

Bus

Input

Outdoor Sensor

Included

OR

0-10 or 2-10 V (dc)

from EMS

Output

Up to 4

Modulating

Boilers

Input

115 V (ac)

Power Supply

Input

Flow OR

C.A. Proof

Output

Up to 4

Boiler Pumps

OR Boiler Enable

Output

DHW Pump

OR

Primary Pump

Output

Combustion

Air Damper

OR Alert

OR

OR

Output

Primary

Pump

Input

DHW OR

Setpoint

Demand

Signal

Input

Boiler

Demand

Signal