tekmar 275 Boiler Control User Manual

Page 17

17 of 48

© 2012 275_D - 11/12

Pump Operation

Section L

Primary Pump Operation

The control includes two primary pump outputs with

capability for sequencing. Primary pump sequencing is

activated through a DIP switch. Only primary pump 1

is operated when pump sequencing is turned off, while

primary pumps 1 and 2 are operated in stand-by mode

when pump sequencing is turned on.

The running times of the primary pumps are logged in the

view menu. To reset these values back to zero, press and

hold the up and down button while viewing this item.

Note: Once primary pump sequencing is selected, DHW

operation is not available. Setpoint operation, however, is

available if primary pump sequencing is selected.

The primary pump(s) will operate when the control receives

an appropriate demand:

External Boiler Demand

tN4 Boiler Demand and that zone’s thermostat has H1

Pump set to On.

DHW Demand and the control is set to DHW Mode 3,

4, or 6.

Setpoint Demand and the control is set to Setpoint Mode

3 or 4.

The primary pump also operates when the control is

completing a DHW Purge.

tN4 thermostats can select whether the primary pump is

required to operate or not. tN4 thermostats also include a

thermal actuator setting which can delay the primary pump

for 3 minutes to allow thermal actuators to open.

Flow Proof

The control includes a flow proof demand in order to prove

flow once a primary pump has turned on. In order for

boiler operation to commence, the proof demand must be

present. A flow proof signal is required at all times during

pump operation. A flow proof is generated by applying a

voltage between 20 and 260 V (ac) across the Flow Proof

terminals (30 and 31). Once voltage is applied, the Proof

Demand indicator is turned on in the LCD.

Once a pump contact is turned on, a flow proof signal must

be present before the flow proof delay has expired.

The flow proof demand is selected by setting the Proof

Demand item in the Adjust menu to F P (flow proof).

A flow proof demand can come from a flow switch, pressure

differential switch, current sensing or power sensing device.

Dem

Dem

Pr.

Com

31

30

L

N

20 to 260 V (ac)

ΔP

Pressure Differential Switch

FS

Flow Switch

KW

Power Sensing Device

Amp Current Sensing Device

•

•

•

•

Stand-by Operation

The control only operates one primary pump at a time. A

flow proof device can be used to detect when stand-by

pump operation is required.

When a demand is registered, the lead pump is activated,

and the control waits for flow to be established within the

flow proof delay time.

If no flow is established, the lead pump is de-activated,

the lag pump is activated and the control waits again for

the flow to establish within the flow proof delay time.

If again no flow is established, the lag pump is de-activated

and the control stops operation until the error is cleared.

Verify that the pumps and flow proof device are working

correctly before clearing the error.

If the lead pump establishes flow, and fails during

operation, the lag pump is activated.

If at any time, one or both pumps fail to prove flow, an

error message is displayed.

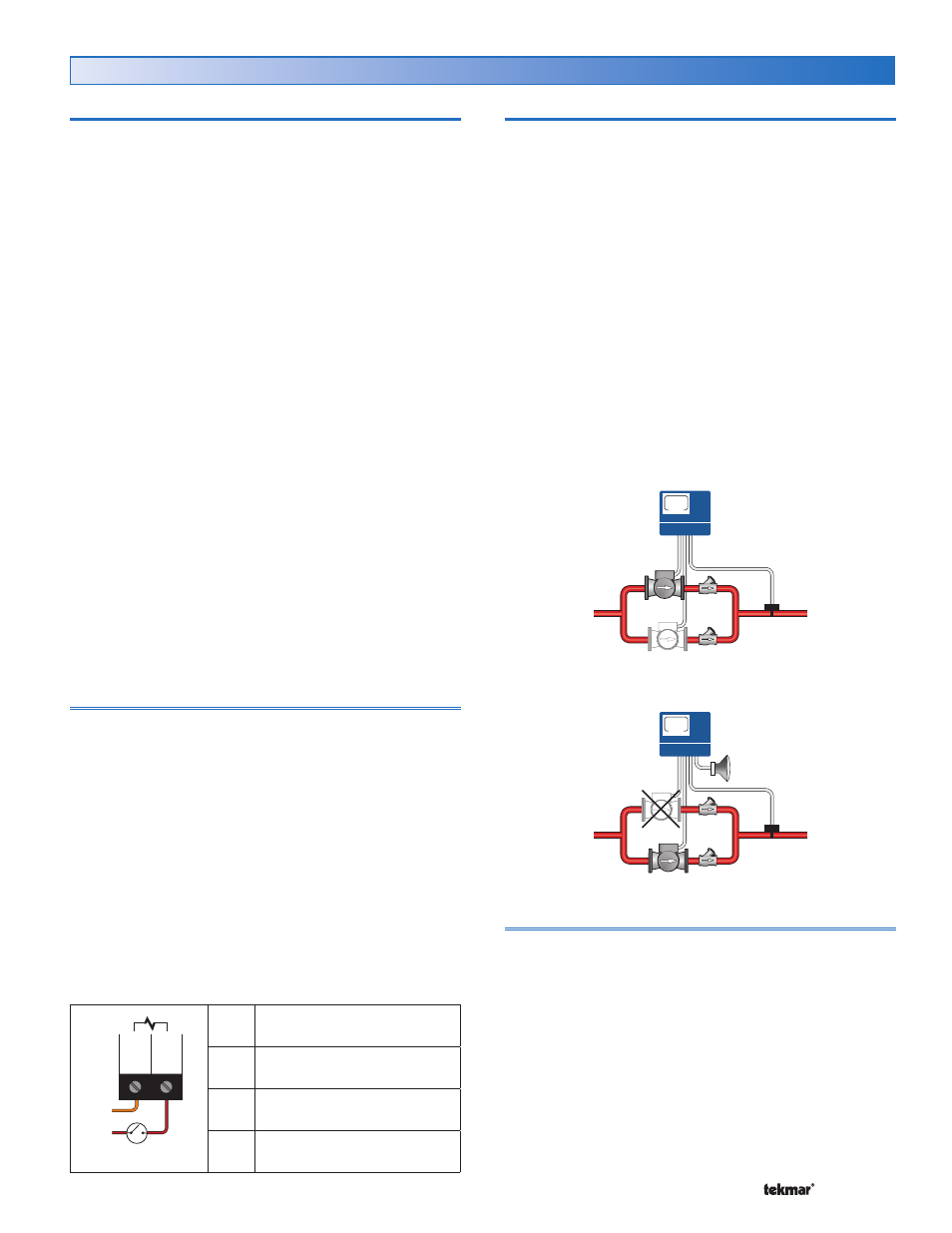

Normal Operation

On

Flow Proof

Device

Off

275

Stand-by Pump Operation

Failed

Optional

Alert

Flow Proof

Device

On

275

Flow Proof Delay Setting in Adjust Menu

The control waits a period of time to receive a flow proof

demand from the time the primary pump turns on. If the

control does not receive a flow proof demand within that

period of time, the primary pump turns off and the stand-by

primary pump (if active) turns on. The control then waits

that period of time again for the stand-by primary pump to

prove flow. If flow is not proven, the stand-by pump turns

off. The period of time is set through the Proof Demand

‘Pump’ DLY item in the Adjust menu and it is adjustable

between 10 seconds and 3 minutes.

•

•

•

•

•