Changing action (direct acting actuators) – Powers 593 Series Flowrite II Heavy Duty Bronze Globe Control Valves User Manual

Page 6

6

CHANGING ACTION (DIRECT ACTING ACTUATORS)

All valve bodies used with Flowrite II Actuators are push-to-close.

Directing Acting actuators make the valve action Normally Open

(NO, DA, ATC); Reverse Acting actuators make the valve action

Normally Closed (NC, RA, ATO).

Changing the action of the actuator (DA to RA or RA to DA) will

therefore reverse the valve action from NO to NC, or NC to NO.

To change the actuator action, you change the stem and reverse the

order of the spring, diaphragm and thrust plate assembly.

Change Actuator Action from DA to RA or NO to ATC or NC

to ATO:

1. Shut off controlled medium supply (steam, water, or other

liquid).

2. Reduce preload on the springs (refer to Decreasing Preload

on DA Actuators).

3. Remove the control signal to the actuator.

4. Remove top housing nuts and bolts.

5. Remove upper housing. Remove stem nut, silver and black

washer. (Fig 2A).

6 Remove diaphragm, thrust plate and springs (Fig. 2B).

7. Hold the actuator stem in place and loosen the valve stem

locknuts (turn locknuts counterclockwise a number of times).

8. Hold actuator stem and tighten the two lock nuts together.

Turn the locknuts counterclockwise to rotate the valve stem

until the two stems are separated. (Fig. 3)

9. Pull actuator stem upward and remove from assembly

(Fig. 4).

10. Replace with RA actuator stem. Position stem with flats

pointing downward.

11. Thread valve stem into actuator stem by turning the locknuts

clockwise. Tighten by hand.

12. Place black washer on actuator stem. Invert diaphragm and

place inside of lower housing over the black washer. Invert

thrust plate and place on top of diaphragm. (Fig. 5)

13. Replace silver washer and tighten stem nut.

14. Place springs on thrust plate in same orientation as found in

lower housing. Properly seat springs over spring guides

(Fig. 6).

15. Replace upper housing assembly and tighten housing nuts

and bolts. (Fig. 1)

16. Connect control signal to 1/4" NPT fitting located on

bottom of actuator housing.

17. Adjust the preload per instructions on pg. 7.

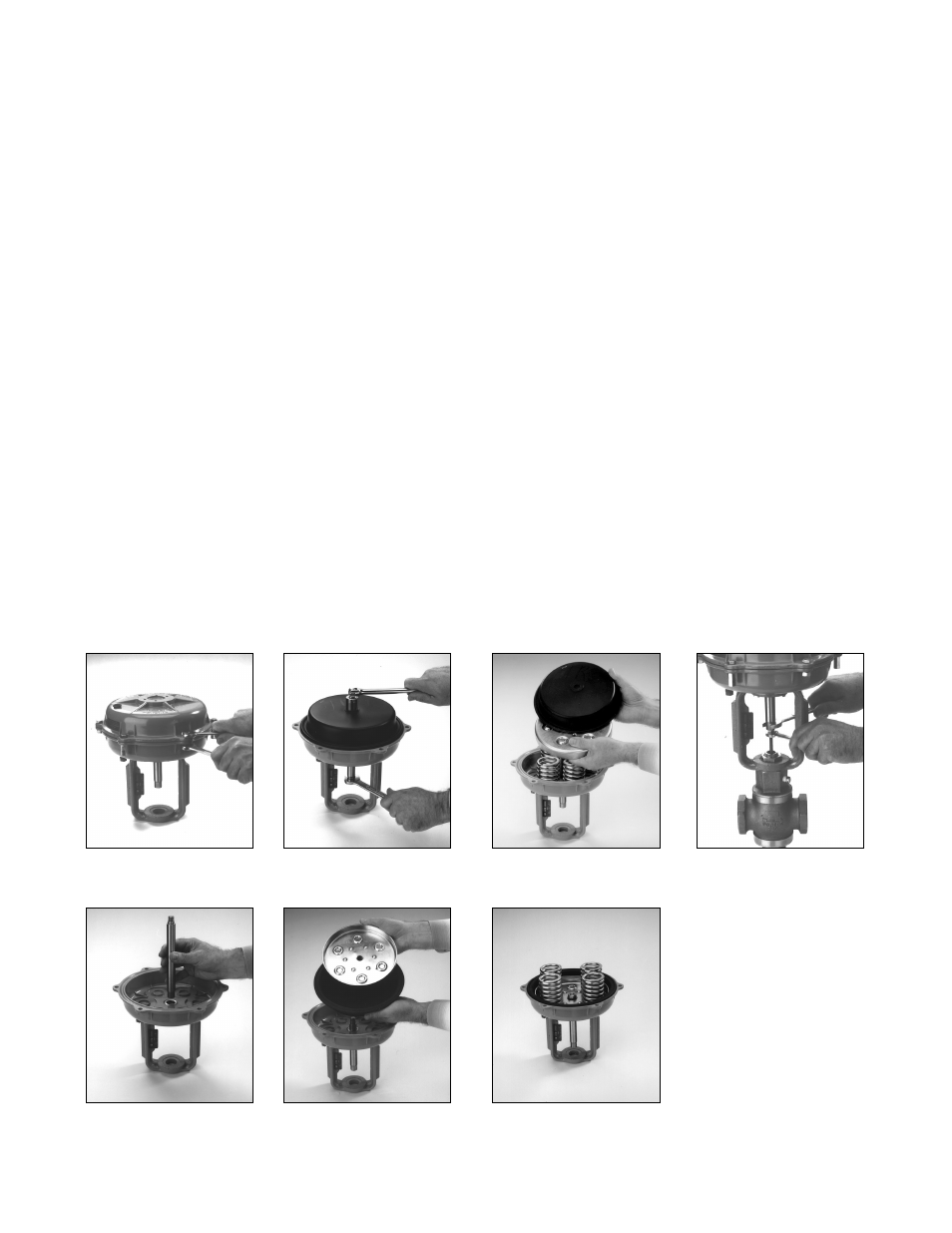

Fig 1 - Remove Housing Bolts

Fig 2A - Remove Upper Housing,

Stem, Nut and Washers

Fig 2B - Remove Diaphragm

and Thrust Plate

Fig 3 - Loosen Stem Locknuts

Fig 4 - Remove Stem

Fig 5 - Reverse Replacement of

Diaphragm and Thrust Plate

Fig 5 - Reverse Replacement of

Diaphragm and Thrust Plate.

Four (4) springs shown. See

note on page 5.