Changing springs (direct acting actuators), Installing an actuator – Powers 593 Series Flowrite II Heavy Duty Bronze Globe Control Valves User Manual

Page 4

4

CHANGING SPRINGS (DIRECT ACTING ACTUATORS)

Springs can be changed or added if a higher shutoff rating is

required. This may become necessary under the following

conditions:

1. If the pressure of the medium passing through the valve increases,

2. If the valve size increases due to an increase in process demand, or

3. If valve body type is changed.

The Modification Data Tables (page 13-15) provide dimensional

data including part numbers, and number of springs required to

reconfigure an actuator.

Springs may be changed with the actuator assembled or removed

from the valve. For ease of instruction, pictures are shown with

actuators removed.

To change or add springs on a Direct Acting (DA, NO, ATC)

actuator assembled to the valve, follow steps 1, 2, 3, 4A, 5-10.

To change or add springs on a Direct Acting (DA, NO, ATC)

actuator removed to the bench, follow steps: 1-4A, 5-9.

To change or add springs on a Direct Acting (DA, NO, ATC)

actuator assembled to the valve and under preload, follow steps:

1, 3, 4B, 5-10.

1. Shut off controlled medium supply (steam, water, or other

liquid).

2. Reduce preload on the springs (refer to Decreasing Preload

on DA Actuators pg. 7).

3. Remove the control signal to the actuator.

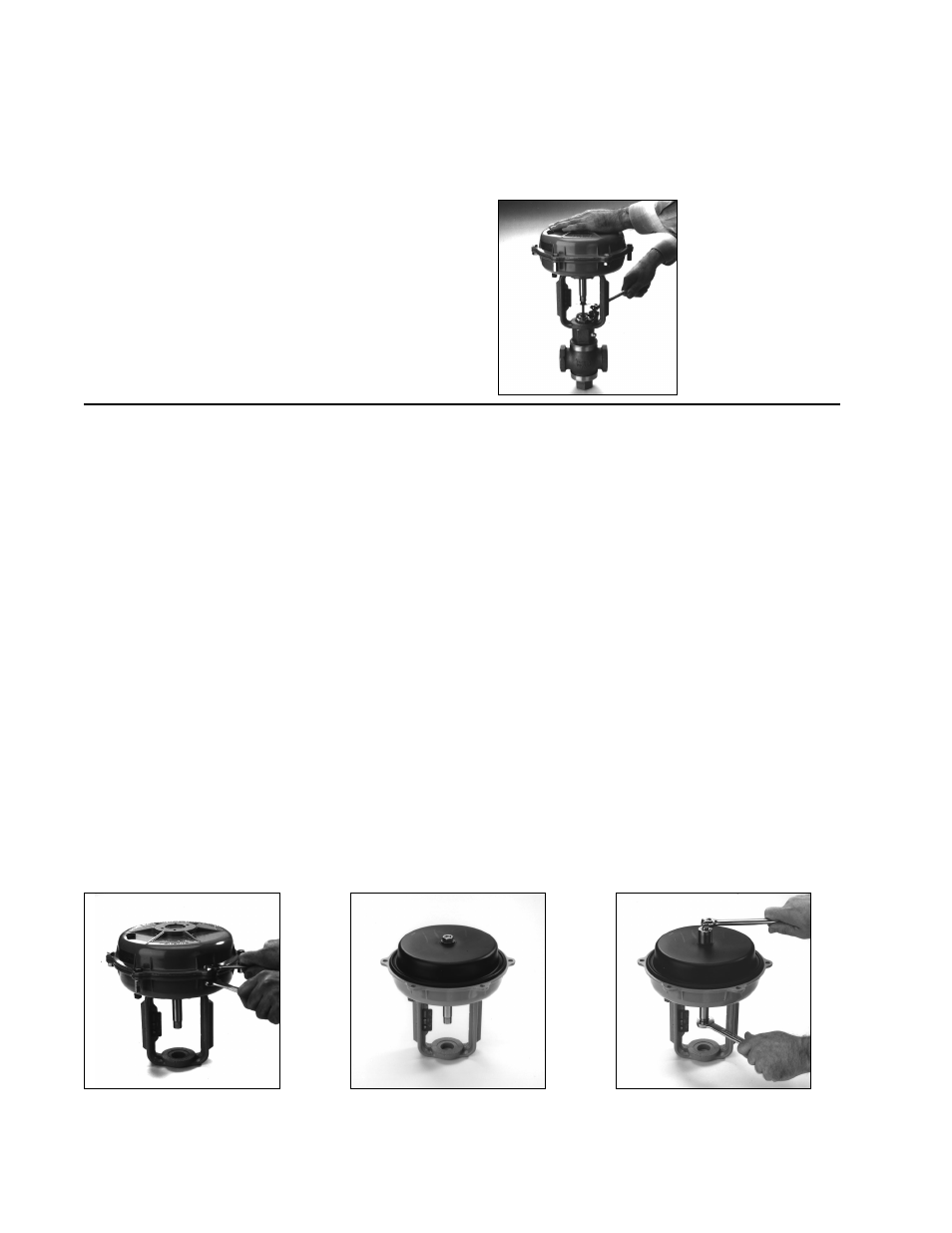

4A. (Fig. 1) Remove top housing nuts and bolts or (see above)

4B. (Fig. 1) Remove the three bolts attached to the short nuts,

then equally release the bolts attached to the long nuts.

CAUTION: Springs under tension.

5. (Fig. 2A) Remove upper housing.

6. Remove stem nut, silver and black washers (Fig. 2B).

7. Remove diaphragm, and thrust plate (Fig. 2C).

8. Change or add springs as needed (Fig. 3A & 3B). Make sure

the springs are properly placed over the spring guides

and their configuration is symmetrical.

9. Reassemble parts in reverse order, then attach upper housing.

10. Adjust preload ref.

NOTE: Some actuator models have small springs nested inside

the larger springs. The small springs also fit over spring guides

and must also be placed symmetrically.

Fig 1 - Remove Housing Bolts

*(extended versions last and gradually)

Fig 2A - Remove Upper Housing

Fig 2B - Remove Stem Nut, & Washers

INSTALLING AN ACTUATOR

1. Place actuator assembly over valve stem. With actuator stem and

valve stem separated, place bonnet lock nut over valve stem onto

bonnet.

2. Apply air pressure to the actuator approximately 9 psi for a

Normally Closed valve assembly, and 3 psi for a Normally Open

Assembly.

3. Tighten the valve stem to the actuator stem by rotating the valve

stem (NOT THE ACTUATOR STEM).

4. Tighten the two locknuts together and rotate them clockwise.

Tighten the nuts to achieve the proper PRELOAD (as explained in

the Preload Section).

5. Remove air pressure.

6. Tighten the bonnet locknut on the bonnet (Fig.1).

Fig 1 - Tighten the Bonnet

Lock Nut on the Bonnet