Changing springs (reverse acting actuators) – Powers 593 Series Flowrite II Heavy Duty Bronze Globe Control Valves User Manual

Page 5

CHANGING SPRINGS (REVERSE ACTING ACTUATORS)

Springs may be changed with the actuator assembled or removed

from the valve. For ease of instruction, pictures are shown with

actuators removed.

To change or add springs on a Reverse Acting (RA, NC, ATO)

actuator assembled to the valve, follow steps 1-4A, 5-8.

To change or add springs on a Reverse Acting (RA, NC, ATO)

actuator removed to the bench, follow steps: 1-4A, 5-7.

To change or add springs on a Reverse Acting (RA, NC, ATO)

actuator assembled to the valve and under preload, follow steps:

1, 3, 4B, 5-8.

1. Shut off controlled medium supply (steam, water, or

other liquid).

2. Reduce preload on the springs (refer to Decreasing Preload

on DA Actuators pg. 7).

3. Remove the control signal to the actuator.

4A. (Fig. 1) Remove top housing nuts and bolts or (see above).

4B. (Fig. 1) Remove the three bolts attached to the short nuts,

then equally release the bolts attached to the long nuts.

CAUTION: Springs under tension.

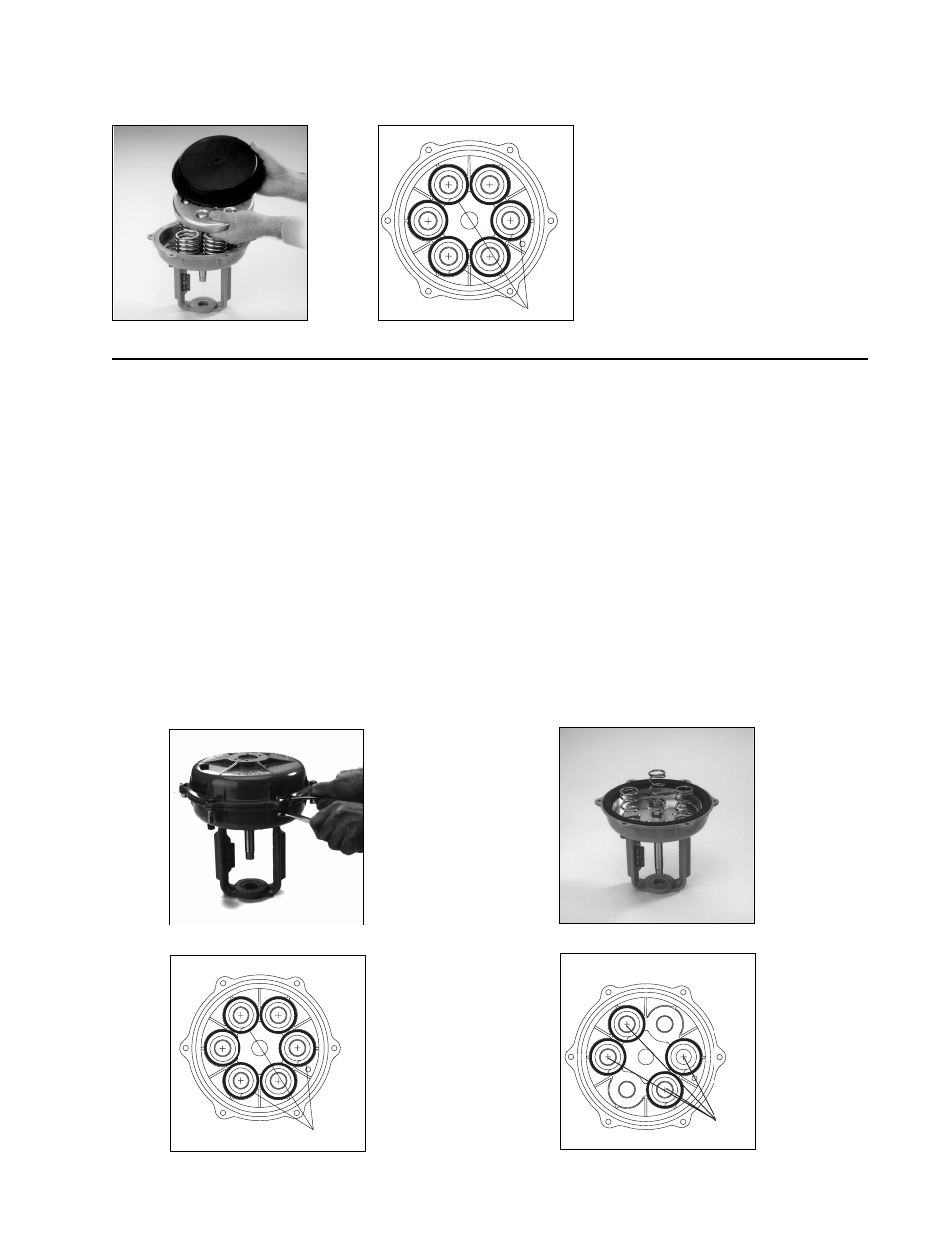

5. (Fig. 2A) Remove upper housing.

6. Add or remove springs as needed for new configuration

(Fig 3A &Fig. 3B). Make sure the springs are properly placed

over the spring guides and their configuration is symmetrical.

NOTE: Some actuator models have small springs nested

inside the larger springs. The small springs also fit over

spring guides and must also be placed symmetrically.

7. Reassemble upper housing.

NOTE: Assemble bolts with long nuts first.

8. Adjust preload ref pg. 7.

Fig 1 - Remove Housing Bolts

Fig 2- Remove Upper Housing

Springs

Fig 3A - Typical 3-Spring Installation

NOTE: *Number required may vary. Refer

to page 14-15.

Springs

Fig 3A - Typical 4-Spring Installation

Fig 2C - Remove Diaphragm,

Thrust Plate

Springs

Fig 3A - Typical-Spring Installation

5