Standstill (under-speed) monitoring applications – Banner Safe Speed Monitoring Modules User Manual

Page 9

Number of pulses per minute at a speed in meters per minute: sensing points/meter × meters/minute

For this example, the number of pulses = 4 pulses/meter × 60 meters/minute = 240 pulses/minute.

To detect a speed greater than 1 meter/second, the switching point must be set slightly higher than 240 ipm; for 4 sensing points: 4

pulses per meter.

Rotational Motion Applications

Depending on the number of sensing points at the motor, the ipm (impulses per minute) can be a multiple of the motor rpm. Use the

following formula to calculate the number of impulses per minute the Module will see from the two sensor outputs: rpm x number of

sensing points per sensor = ipm

If each sensor sees one sensing point per motor turn, then rpm = ipm.

Examples:

• At 1000 rpm with 1 sensing point per turn per sensor: 1000 x 1 = 1000 ipm

• At 1000 rpm with 2 sensing points per turn per sensor: 1000 x 2 = 2000 ipm

Because more sensing points per sensor are interpreted by the Module as a higher rpm, the more sensing points used, the closer the

switch point can be set to 0 rpm.

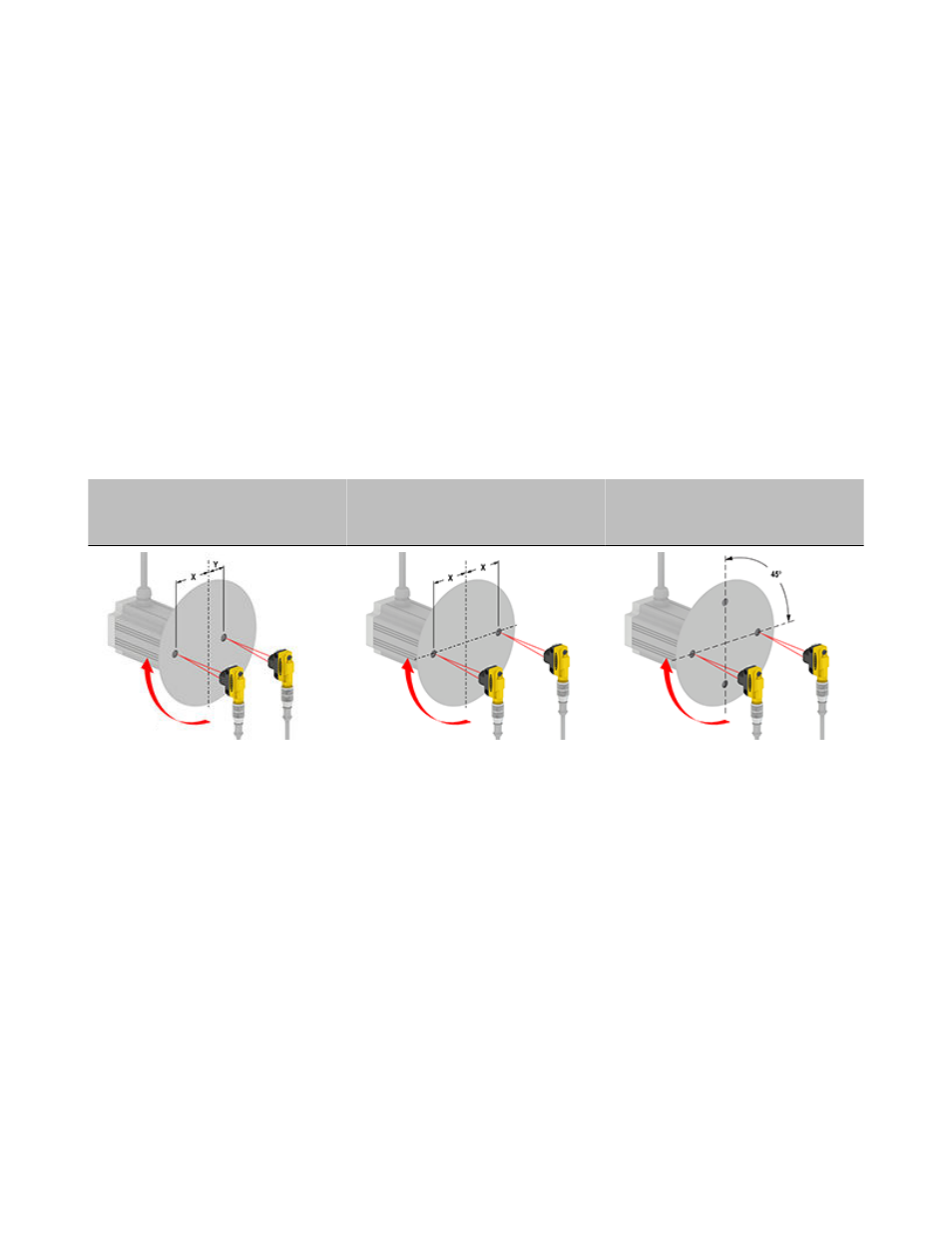

NOTE: Both sensors must always sense their sensing points at the exact same time, so that the two Module inputs receive the pulses at

the same time. If two sensing points are used per sensor, they must be offset by 180°. If four sensing points are used, they must be

offset by 90° of each other (see figures).

Each sensor sends one pulse per revolu-

tion to the Module (500 rpm = 500 ipm).

Each sensor sends two pulses per revo-

lution to the Module (500 rpm = 500 x 2 =

1,000 ipm).

Each sensor sends four pulses per revo-

lution to the Module (500 rpm = 500 x 4 =

2,000 ipm).

Two sensing points at different distances

from the center of the disk.

Two sensing points at the same distance

from the center of the disk

Four sensing points at the same distance

from the center of the disk

Standstill (Under-speed) Monitoring Applications

Because the pulses that define the detected speed are created by sensors that monitor the moving or rotating part (work piece or tool),

speed sensing is independent of the supply voltage of the monitored motor.

The two input channels are factory pre-adjusted for reliable switching simultaneity of the sensor inputs. A channel fine-tuning potentiome-

ter inside the Module housing (behind the front cover) provides exact simultaneity.

SSM-FM-11A... Safe Speed Monitoring Modules

P/N 140782_web

rev. C

www.bannerengineering.com - tel: 763-544-3164

9