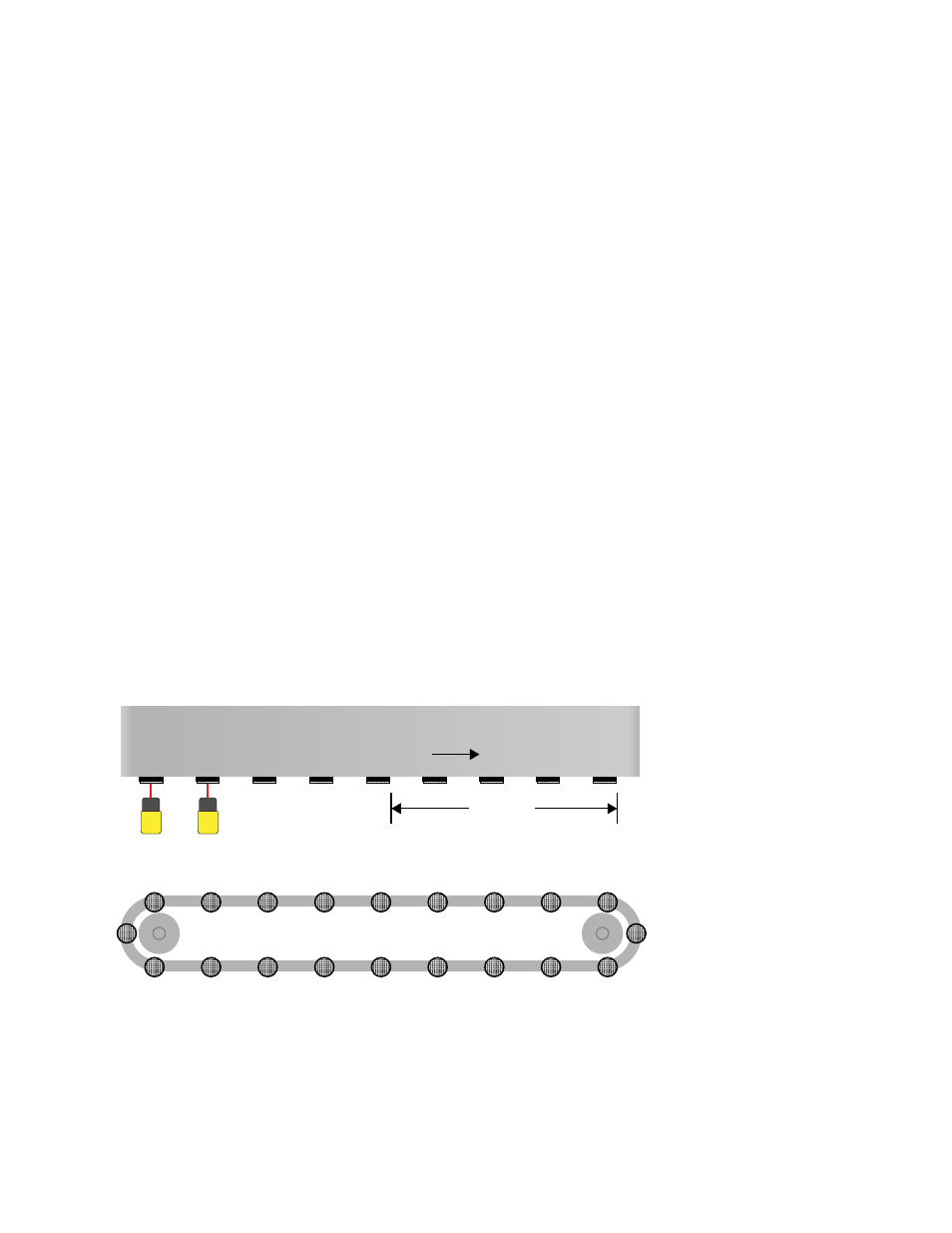

Conveyor (top view), Conveyor (side view), Adjusting simultaneity – Banner Safe Speed Monitoring Modules User Manual

Page 8: Linear or rotational movement

• Selected range: 300 to 2,700 ipm

• Potentiometer range delta: 2,700 ipm minus 300 ipm = 2,400 ipm

With the potentiometer dial all the way to the left (counterclockwise), the switch point is at 300 ipm. To increase the setting to 1,400 ipm,

1,100 ipm (1,400 minus 300 = 1,100 ipm) must be added:

[270 degrees ÷ 2,400 ipm (total range)] x 1,100 ipm = 123.75 degrees

Starting from the left, turn the potentiometer dial 123.75° clockwise. The middle position of the potentiometer is 135° (or 1,200 ipm), so

the setting is just a few degrees right from the middle position. This method provides only an approximate value.

More Precise Method

Measure the motor speed, including the speeds to be detected as over-speed, under-speed or zero speed (standstill), using an rpm

meter.

Adjusting Simultaneity

The input channels are factory pre-adjusted; use the simultaneity potentiometer (behind the Module's front cover) to further synchronize

the input channel timing.

1. Start the motor.

The safety output contacts and indicators should turn OFF (safety contacts open), as soon as the motor speed passes the switch

point.

2. Stop the motor.

After the motor speed drops below the switch point value and after the selected delay time, the safety output contacts and indicators

should turn ON.

3. If only one of the two channels detects the low-speed condition, restart the motor and turn the simultaneity potentiometer a few de-

grees clockwise (or counterclockwise, depending on which of the two channels switched first) to adjust the simultaneity. Repeat this

procedure until both channels detect standstill and turn OFF both internal relays simultaneously.

Linear or Rotational Movement

The Module can monitor either linear or rotational motion because it looks only for pulses on its two inputs.

Linear Motion Applications (Monitoring the Speed of a Conveyor)

Conveyor (top view)

Sensor

1

Sensor

2

Speed = 1 meter per second

Reflectors

Conveyor (side view)

1 meter

Figure 7. Linear Motion Detection

Module should monitor conveyor for max. speed of 1 meter/second.

Sensing points per meter = pulses per meter: 1 per 0.25 meter = 4 per meter

Max. speed: 1 meter/second = 60 meters/minute

SSM-FM-11A... Safe Speed Monitoring Modules

8

www.bannerengineering.com - tel: 763-544-3164

P/N 140782_web

rev. C