Overview, Warning, Caution – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 6

4

P/N 68413 rev. A

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN Point

Instruction Manual

Overview

WARNING . . .

Use of Trip Output

Application of power to the EZ-SCREEN Point

System(s) MUST NOT initiate dangerous machine

motion.

Machine control circuitry must be designed so that one or more

initiation devices must be engaged (i.e. a conscious act) to start the

machine in addition to the EZ-SCREEN Point System(s) going into

RUN mode.

Failure to follow these instructions could result in serious

bodily injury or death.

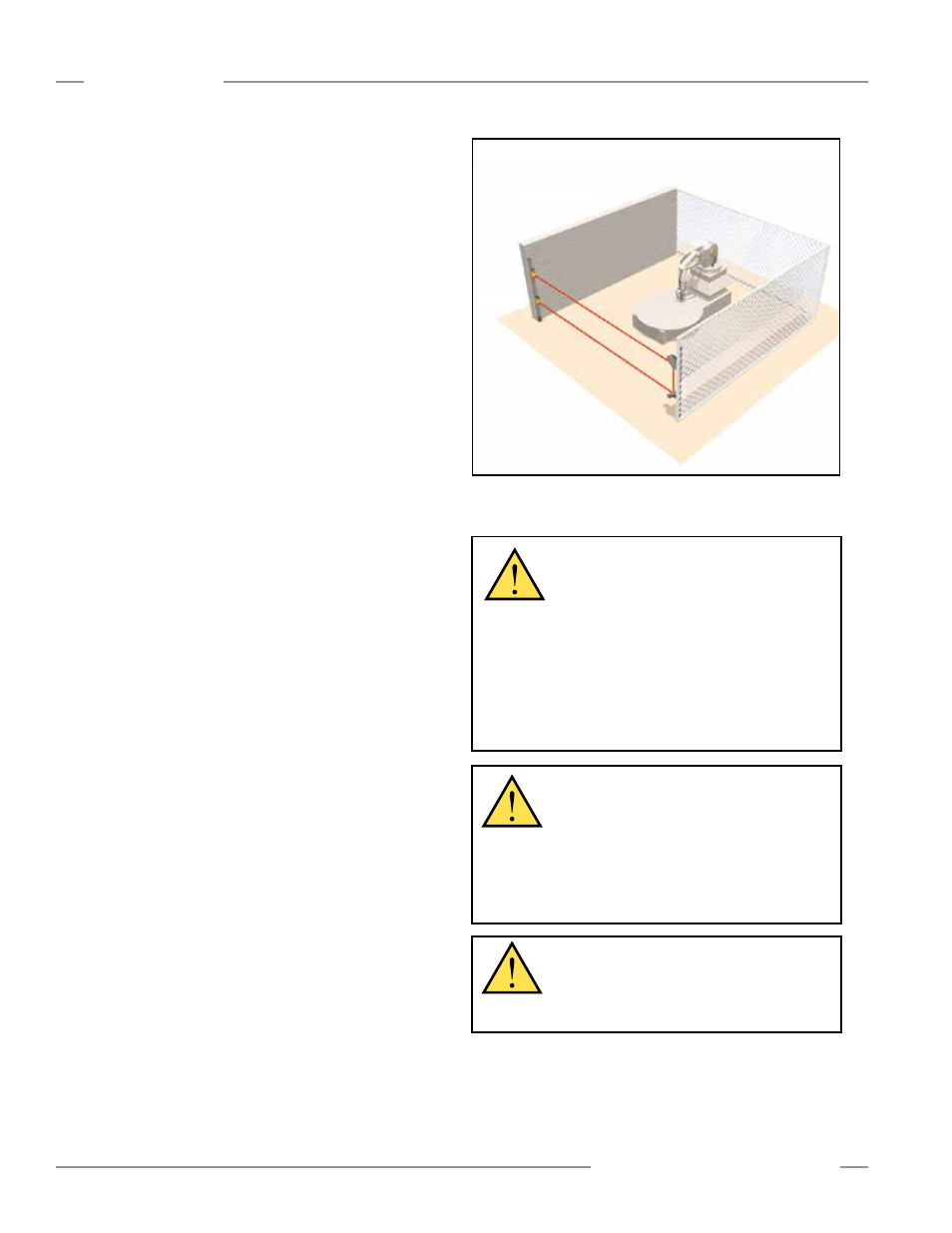

Figure 1-4. EZ-SCREEN Point access-guarding configuration

(short-range emitter only)

Emitter

Receiver

Hard Guarding

Hard Guarding

Hard Guarding

Mirror #1

Mirror #2

CAUTION . . .

Other Applications

For applications not covered in this manual,

contact a factory applications engineer before installing

or using the EZ-SCREEN system.

WARNING . . .

Switch Configuration

of Multiple EZ-SCREEN Systems

When multiple EZ-SCREEN Point Systems are

used to form one grid, they must all be set to the same output

mode (Trip or Latch).

Failure to follow these instructions could result in serious

bodily injury or death.

Pass-through hazards: Perimeter- and access-guarding

applications must be designed to prevent pass-through hazards .

A pass-through hazard occurs when an individual is allowed to

cross the safeguard (which issues a stop command to remove

the hazard). Subsequently, the person may cross into the

hazardous area but their presence is no longer detected . A

danger arises because the machine’s dangerous motion may

resume while personnel are within the safeguarded area. Several

measures can be taken to prevent a pass-through hazard, which

include, but are not limited to:

• A latching output on the EZ-SCREEN System(s) guarding the

access or perimeter to the hazardous area, which requires

a manual reset procedure before machine motion can be re-

initiated. The Reset switch has several requirements, including

its placement outside of the guarded area, and out of reach of

anyone inside the guarded area. In addition, the Reset switch

operator must have full view of the entire guarded area during

the reset procedure .

• Supplemental safeguarding, such as described by the ANSI

B11 series of safety requirements or other appropriate

standards, to prevent personnel from standing undetected

within the guarded area.

In addition, hard guarding should be installed around the

hazardous area to prevent personnel from entering the guarded

area, undetected by the light beams, or other safeguarding

means .

Because the EZ-SCREEN Point has a selectable (latch or trip)

output, it must be installed and configured to prevent hazardous

motion from occurring while personnel are within the guarded

area. See Section 4.1 for more information.

EZ-SCREEN Point may be used to guard many types of

machines, including those for packaging, palletizers, roll

formers and many types of work cells, including robot cells. The

guarded machine(s) must be capable of stopping at any point in

their motion; see page 2 for a complete list of requirements for

machines that may be guarded by this system .