System installation – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 30

28

P/N 68413 rev. A

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

EZ-SCREEN Point

Instruction Manual

System Installation

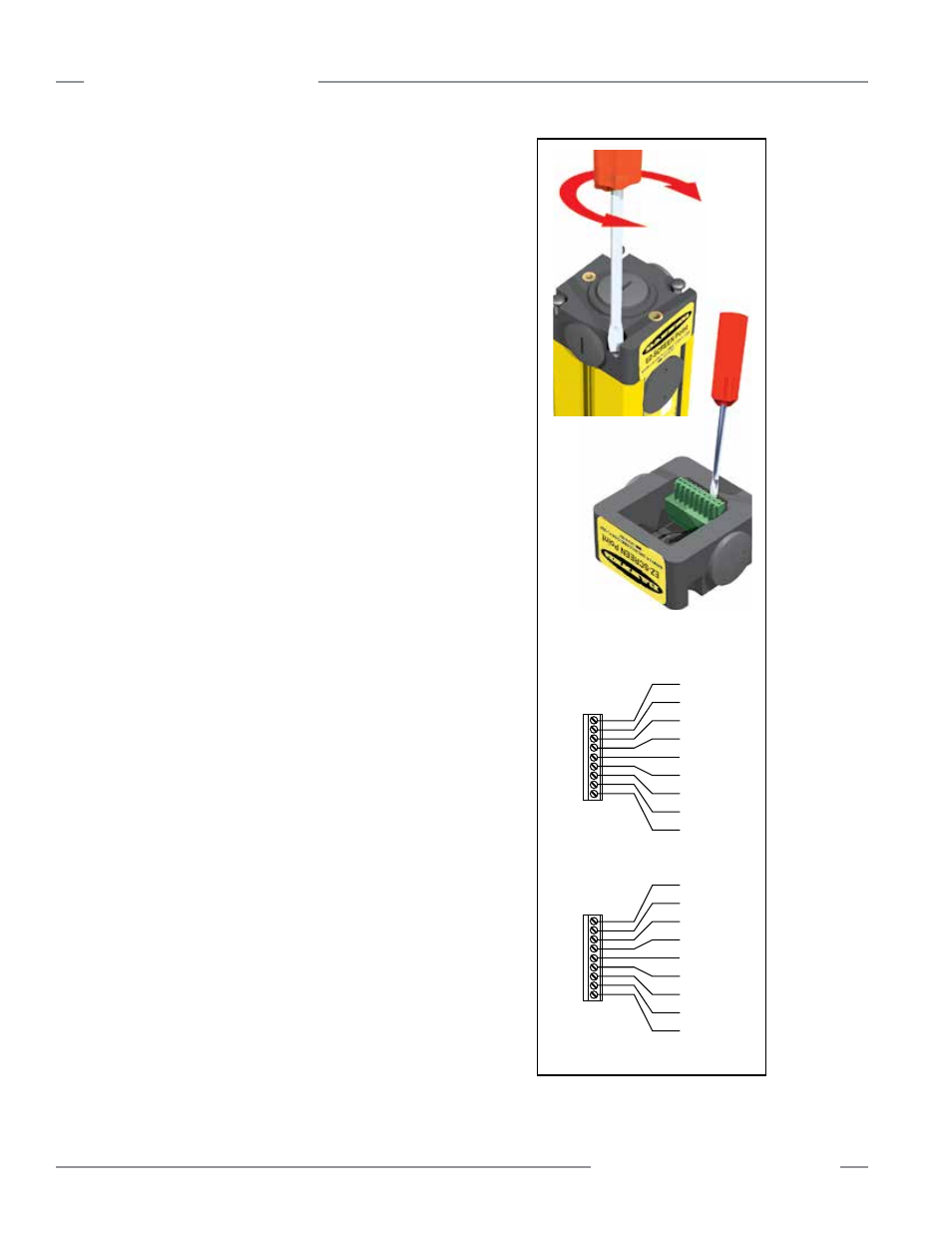

For easy wiring, each EZ-SCREEN sensor has a removable

modular terminal block inside one end cap, at the same end as

the indicators (See Figure 3-14). To make connections:

1. Remove the wiring chamber end cap by unscrewing the four

captive screws in the end cap corners.

2. Remove the terminal block from the end cap.

3. Remove one or more of the three Pg13.5 plugs, as needed,

from their threaded access ports, using the accessory

spanner wrench. Insert conduit or a cable gland into the

port; screw snugly into place. Follow the specific installation

instructions and/or recommendations supplied by the

hardware manufacturer. Unused access ports should remain

factory sealed to maintain NEMA 4, 13; IEC IP65 rating.

4. Route the wires or cabling through the bracket (if necessary)

and the wiring chamber end cap. Remove outer cable

insulation as necessary (approximately 1" to 2") and strip the

individual wire insulation approximately 7 mm (0.25"); make

connections to terminals as indicated in Figure 3-14. Torque

the terminal screws to 0.22 to 0.25 N m (1.9 to 2.2 in. lb.)

recommended torque .

Emitter: If Test input will be used, connect the wires at the

emitter terminal block and temporarily connect the other ends

of the wires to each other (but not to an external contact at

this time).

If Test input will not be used, leave the factory jumper in

place .

Terminals 7, 8 and 9 are provided to allow convenient power

connection (24V dc, 2 amp max.) to another EZ-SCREEN

emitter . These terminals are a direct connection to terminals

3, 2 and 1 respectively. A 24V dc, 2-amp external fuse is

recommended to limit the current on terminal 7 .

Receiver: While all wires will not be connected to the machine

control circuits at this time, connect the receiver end of all wires

to their connections on the receiver terminal block.

If EDM will not be used (no monitoring), jumper terminals 6 and

7. (A jumper wire is supplied in the hardware kit.)

If 2-channel monitoring will be used, connect the wires to

receiver terminals 6 and 7 and temporarily connect the other

ends of the wires to each other (but not to the machine at this

time).

If 1-channel monitoring will be used, add a jumper between

terminals 6 and 7 for the initial checkout. Final EDM wiring must

be completed later .

5. Recheck the wires to be sure connections are accurate and

that wiring complies with applicable (international, national

and local) codes.

6 . Snap the terminal block back into the end cap . Replace the

end cap on the end of the housing, being careful to align the

end cap terminals with the corresponding terminals in the

housing. When the end cap is screwed back into place on

the housing, the two terminal block sections will automatically

connect .

Figure 3-14 Making connections

to the sensor terminal

blocks

Emitter

Terminal

Block

PE

1

9

dc COM

+24V dc

TEST2

TEST1

(Not Used)

+24V dc

dc COM

PE

Receiver

Terminal

Block

PE

1

9

dc COM

+24V dc

(Not Used)

RESET

EDM1

EDM2

OSSD1

OSSD2