Rockwell Automation 1440-TPR06-00RE XM-360 Process Module User Manual

Page 40

Publication GMSI10-UM006C-EN-P - August 2010

32 Installing the XM-360 Process Module

Connecting a 4-20mA / 0-20mA Input

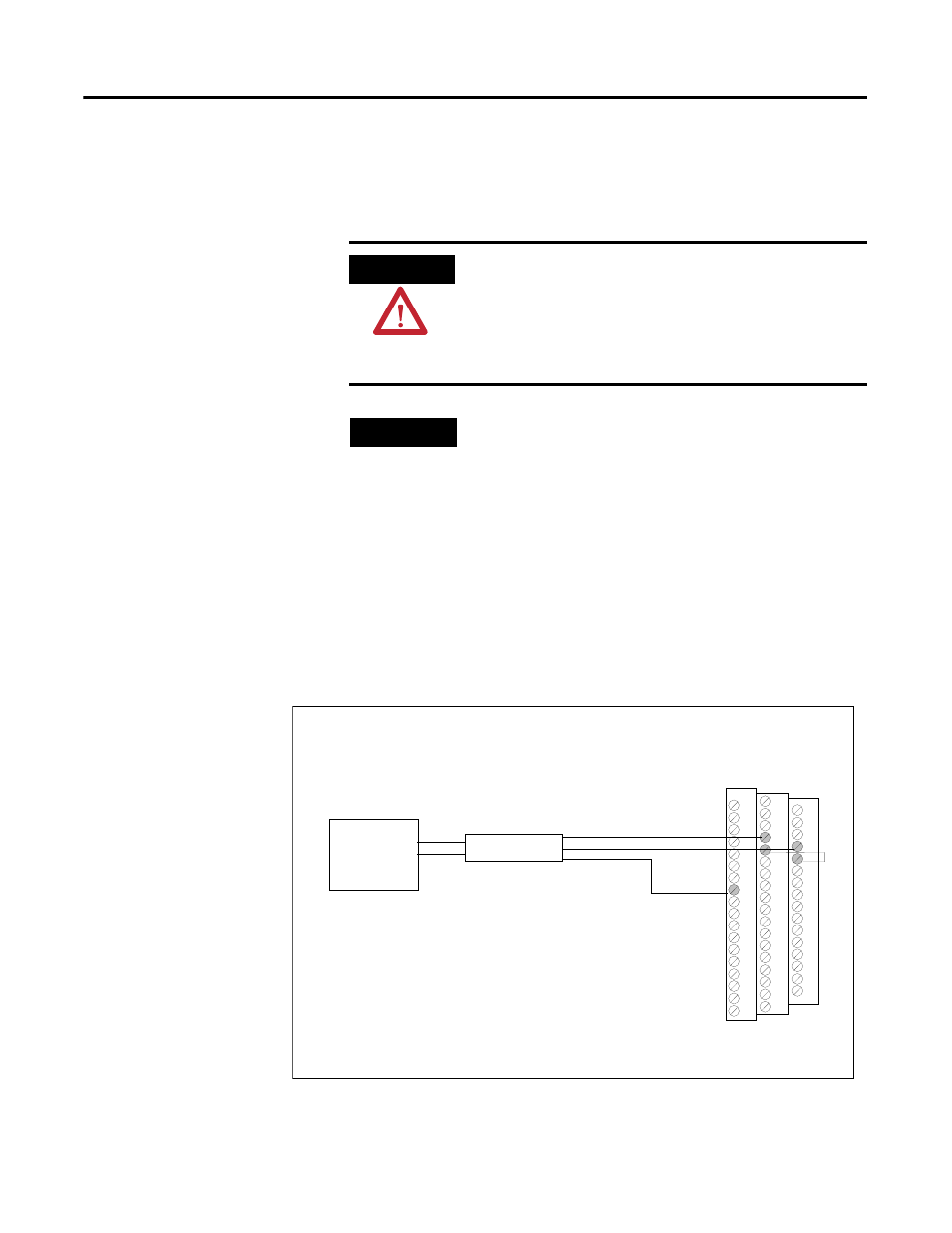

Figures 2.25 to 2.30 show the wiring from a non-loop powered 4-20mA input

to the terminal base unit of the XM-360.

Figure 2.25 Non-loop Powered 4-20mA Input to Channel 1 Wiring

ATTENTION

You may ground the cable shield at either end of the cable.

Do not ground the shield at both ends. Recommended

practice is to ground the cable shield at the XM-360

terminal base and not at the field device. Any convenient

Chassis terminal may be used (see Terminal Block

Assignments on page 17).

TIP

The XM-360 loop-current inputs are low impedance,

approximately 50 ohms. Field devices providing digital

communications (such as HART

®

) on top of their 4-20mA

analog signal may require a minimum loop impedance to

function. This is typically 250 ohms, minimum. If the sum

of the XM-360 input impedance, field wiring impedance,

and other device impedance (such as displays) in the loop

don’t meet this minimum requirement, additional resistance

should be added. Typically this is accomplished by simply

adding a 250 ohm resistor in the loop. Refer to the field

device user manual for details and recommendations.

TYPICAL WIRING FOR NON-LOOP POWERED 4-20mA INPUT

TO XM-360 PROCESS MODULE CHANNEL 1

41

20

19

4-20mA

Transmitter -

+

3

4

RED

BLK

RED

SHIELD

BLK