Rockwell Automation MPAR Electric Cylinders User Manual

Page 9

MP-Series Electric Cylinders 9

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

3.

Attach mounting accessories to the electric cylinder; see

Tighten the fastening screws evenly.

4.

Attach rod-end accessories and the workload.

Be sure the workload center of gravity is centric to the piston rod.

When fastening a rod-end accessory or workload to the piston rod, use two wrenches.

Use one wrench to tighten the mounting nut or rod-end accessory and the other, on the

piston-rod wrench flats, to counteract the applied torque. Be sure that the torque is not

applied to the piston rod and that the piston rod does not rotate.

Attribute

Frame 32

Frame 40

Frame 63

Internal thread of cover screws

M6

M6

M8

Tightening torque, max

(1)

(1)

Unless otherwise noted, the torque value has a ±20% tolerance.

5 N•m

(3.69 lb•ft)

5 N•m

(3.69 lb•ft)

9 N•m

(5.90 lb•ft)

ATTENTION: Damage may occur to the electric cylinder bearings and the feedback

device if sharp impact to the piston rod is applied during installation. Do not strike the

piston rod with tools during installation or removal.

Failure to observe these safety precautions could result in damage to the electric cylinder

and its components.

IMPORTANT

Do not twist or rotate the piston rod. If the piston rod is rotated, the absolute position

of the electric cylinder will be lost and the absolute home position must be

re-established.

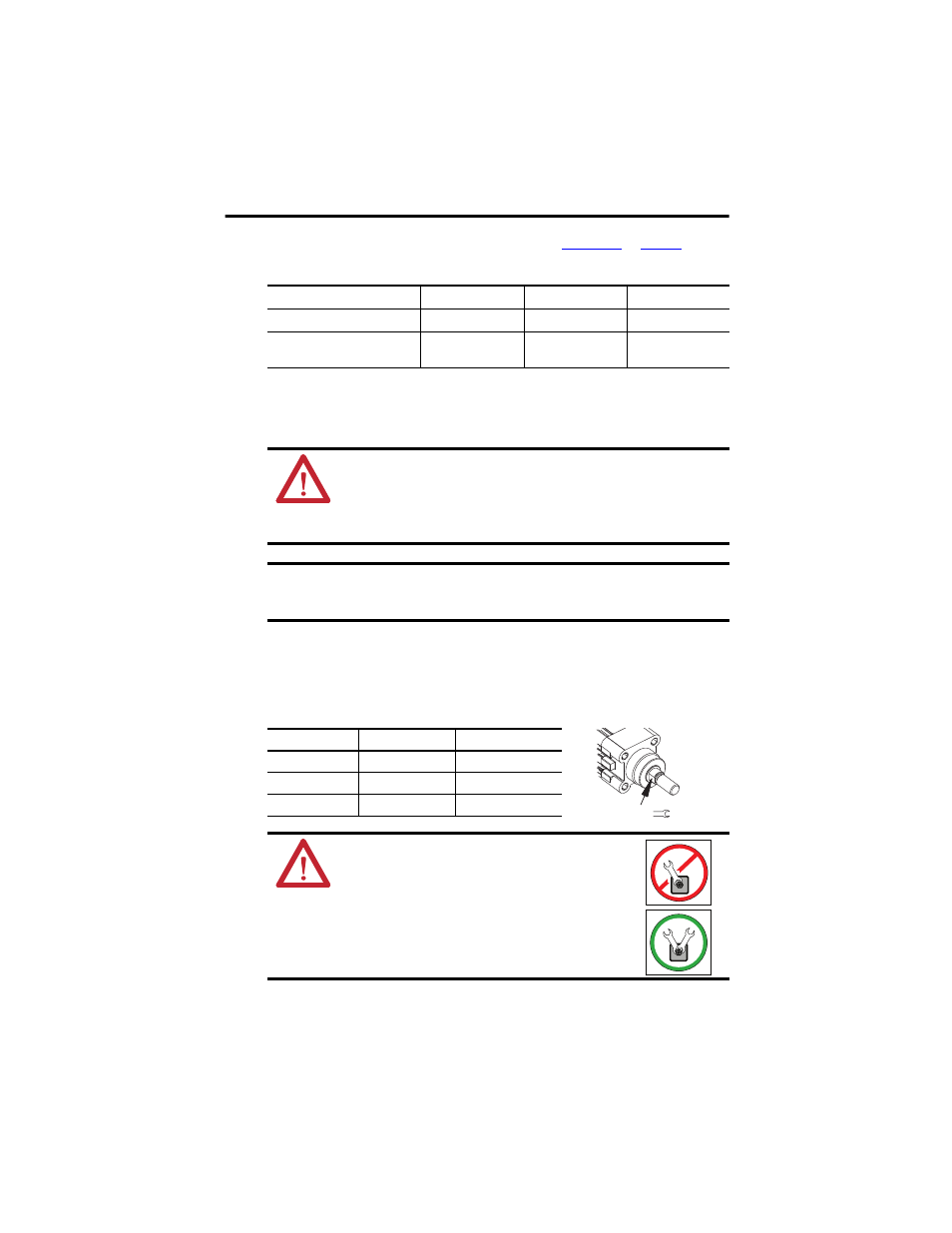

Frame Size

Piston Rod Thread

Wrench Flats Width

32

M10 x 1.25

10 mm

40

M12 x 1.25

13 mm

63

M16 x 1.5

17 mm

ATTENTION: Do not rotate the piston rod during installation.

Rotating the piston rod will break the mechanism that lets the

electric cylinder extend and retract. Use two wrenches to install

the workload.

Failure to observe these safety precautions could result in

damage to the electric cylinder and its components

Wrench Flat