Rockwell Automation MPAR Electric Cylinders User Manual

Page 24

24 MP-Series Electric Cylinders

Rockwell Automation Publication MPAR-IN001D-EN-P - September 2012

2.

Click the Homing tab.

3.

Set parameters for either absolute homing or torque level-to-marker homing as shown on

this table.

4.

Complete these steps for absolute homing.

a. Use motion direct commands to slowly jog your axis to your application's home

location, being sure to not exceed 10 mm/s (0.4 in/s).

b. Issue the Motion Direct Command (MAH) to set the home position on your axis.

5.

Click the Limits tab.

6.

Enter these parameters.

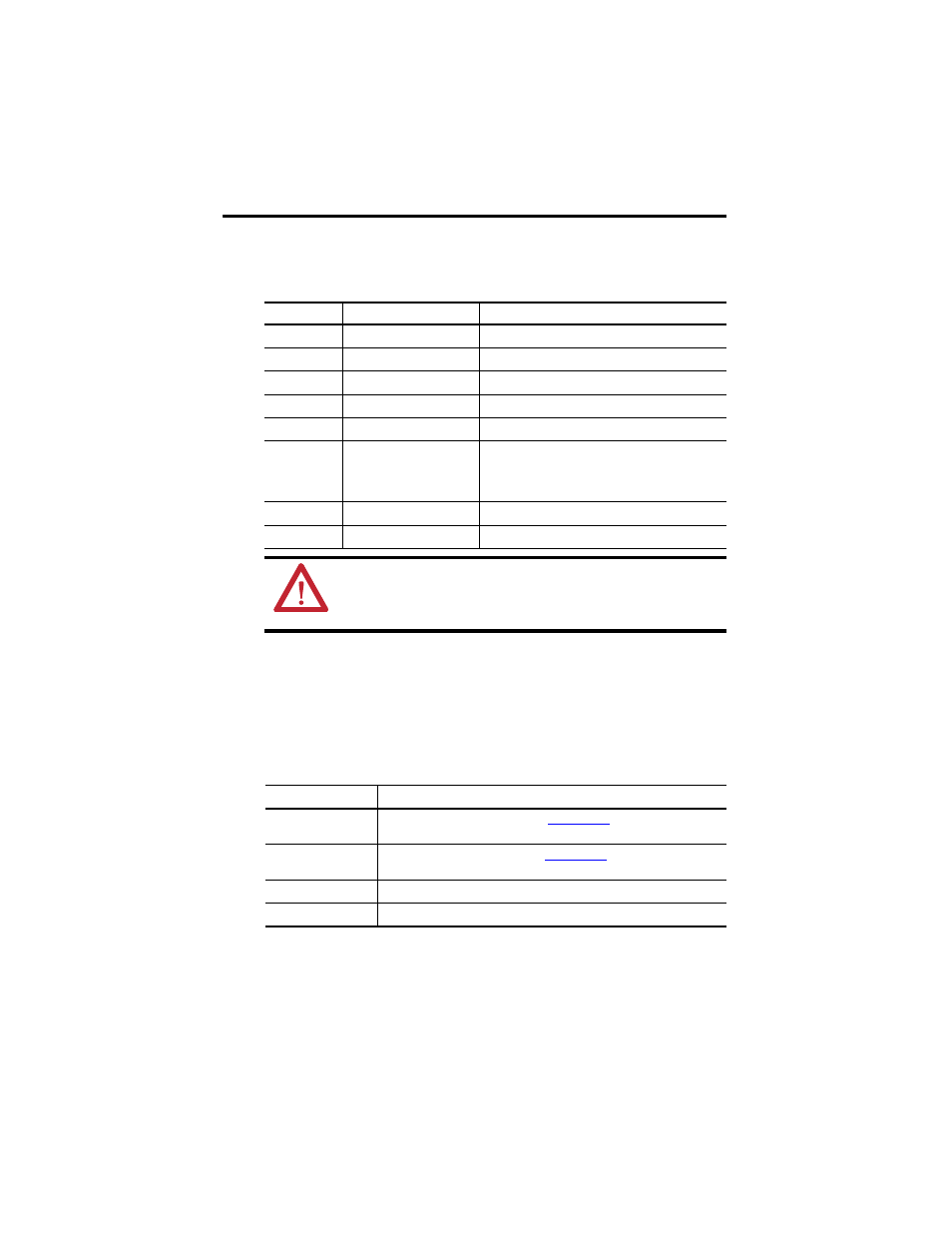

Parameter

Absolute Homing Value

Torque Level-to-marker Homing Value

Mode

Absolute

Active

Position

0, typical

0, typical

Offset

N/A

0 mm

Sequence

Immediate

Torque level-to-marker

Direction

N/A

Reverse bidirectional

Torque Level

N/A

30%, min

Greater if the system friction, force, or weight exceeds 30% of

the Continuous Force Rating at any point in the range of

motion

Speed

N/A

10 mm/s (1.97 in/s)

Return Speed

N/A

10 mm/s (0.39 in/s)

ATTENTION: Avoid excessive force while homing the electric cylinder. Do not exceed

10 mm/s (0.4 in/s) during a home routine.

Speeds greater than 10 mm/s (0.4 in/s) may damage the electric cylinder when the

piston rod reaches the end of travel.

Parameter

Entry/Selection (with applicable distance unit settings)

Hard Travel Limits

Check if hardware limits are in use. Use the

software to determine the

maximum stopping distance in your application to set negative and positive limits.

Soft Travel Limits

Check if software limits are in use. Use the

software to determine the

maximum stopping distance in your application to set negative and positive limits.

Maximum Positive

Enter value that is within the piston-rod mechanical travel.

Maximum Negative

Enter value that is within the piston-rod mechanical travel.