Example range limit setting – Rockwell Automation 5370-CMPK Color CVIM Module MATH-PAK User Manual

Page 60

Chapter 4

Defining Formulas

4–45

Using the learn mode statistics: You can run a series of trial inspections,

using a representative sample of workpieces, with the Color CVIM module

in Learn mode, in order to accumulate a statistical basis for setting the

FAULT

RANGE

and

WARNING RANGE

limits. For more information on

the learn mode, refer to the Chapter 20 in the Color CVIM User’s Manual.

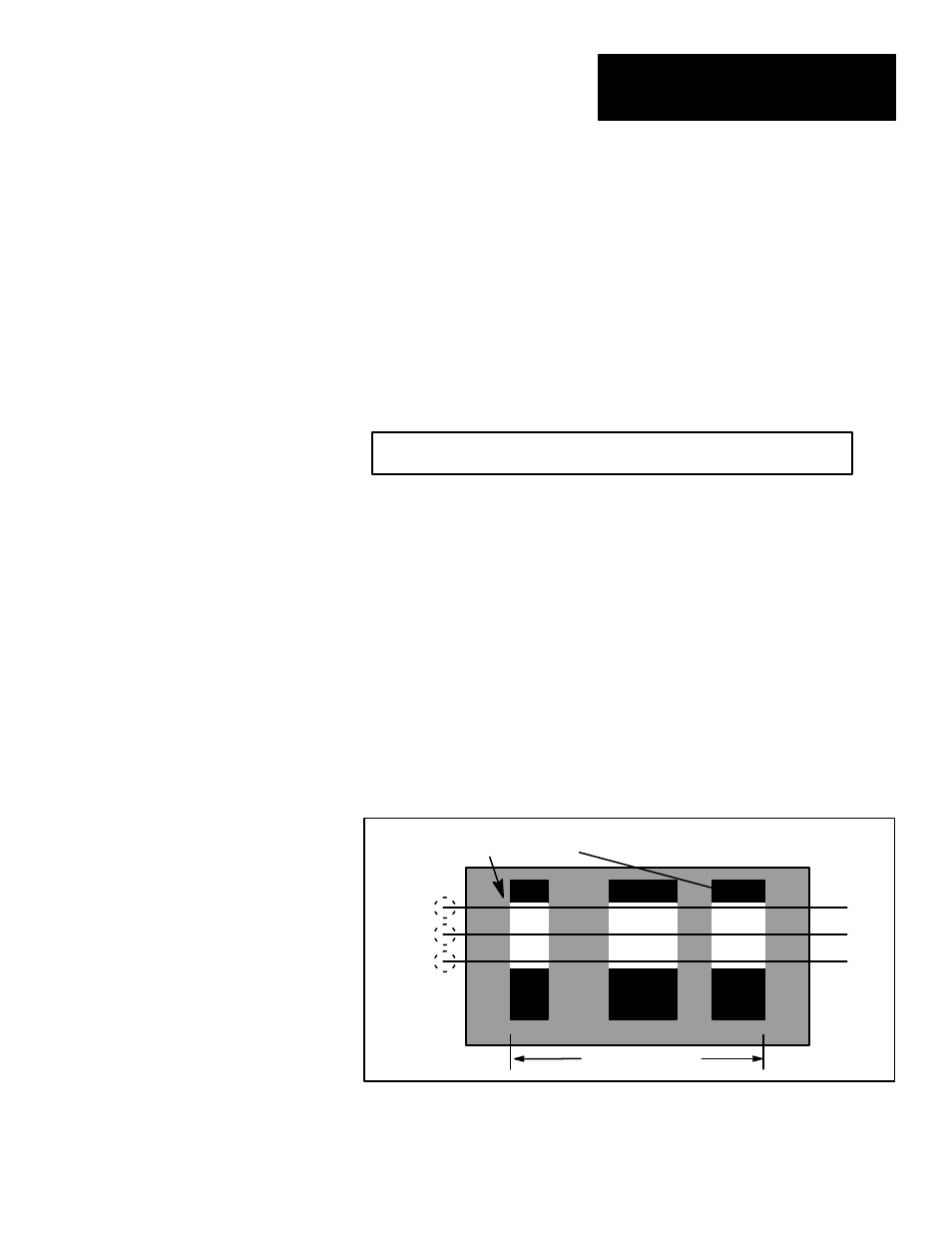

Example Range Limit Setting

Here is an example of setting the range limit values for a formula:

AVG(GAGE1, GAGE2, GAGE3)

which averages the values of three gages (see Figure 4.23), in relation to the

REFERENCE value:

•

The REFERENCE (ideal or nominal) value is 15.000.

•

WARNING

RANGE

–

Low

14.800.

High

15.200.

•

FAULT

RANGE

–

Low

14.600.

High

15.400.

With the range limits set as shown above, if a formula result is outside either

WARNING

RANGE

limit (above 15.200 or below 14.800), but within the

FAULT RANGE

limits, the formula will have a

WARNING

condition only.

If an inspection result is outside either

FAULT

RANGE

limit (above 15.400

or below 14.6), the formula will have both a

WARNING

and a

FAULT

condition.

Figure 4.23 Example: Range limits for linear gaging

A

B

15 cm (Ideal)

Gages measure distance

from feature A to feature B

A

B

A

B

Gage 1

Gage 2

Gage 3

Here is an example of setting the range limit values for a conditional

operation by a formula (see Figure 4.24, page 4–46), where the

REFERENCE value, 1, is the only acceptable value: