Interfacing to the pid instruction, Interfacing to the pid instruction -5 – Rockwell Automation 1746-NT4 Series B,D17466.6.1 SLC 500 4-Channel Thermocouple/mV Input Module User Manual User Manual

Page 75

Publication 1746-UM007C-EN-P - July 2004

Ladder Programming Examples 6-5

Interfacing to the PID

Instruction

The thermocouple module was designed to interface directly to the

SLC 5/02 or later processor PID instruction without the need for an

intermediate scale operation.

Example - Use NT4 channel data as the process variable in the PID

instruction.

1. Select scaled-for-PID as the data type in the channel

configuration word.

2. Specify the thermocouple channel data word as the process

variable for the PID instruction.

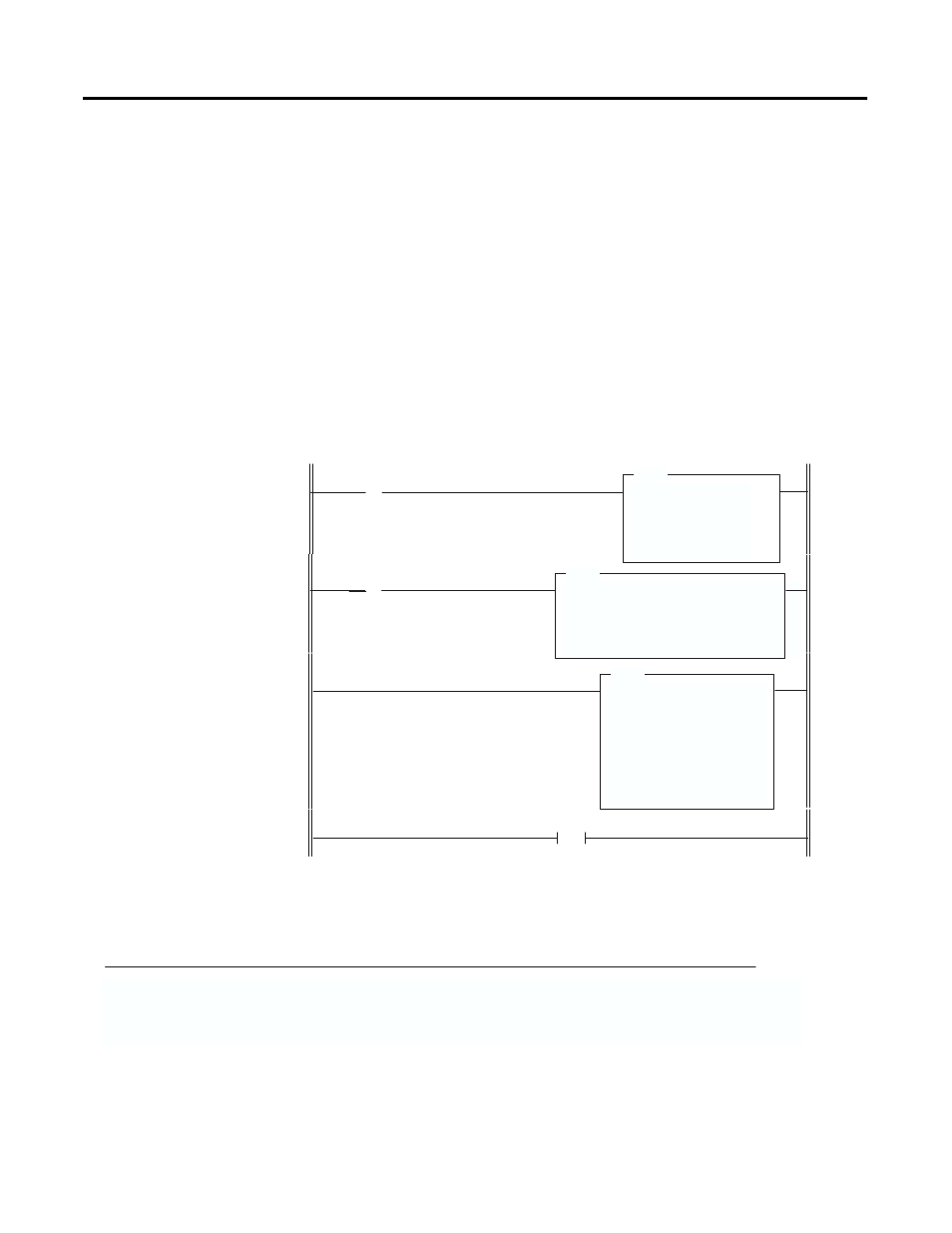

Program Listing

PID

Control Block N11:0

Process Variable

I:3.0

Control Variable

N11:23

Control Block Length23

] [

MOVE

Source N10:0

2081

Dest

O:3.0

0

First Pass Bit

S:1

15

Channel 0

Rung 2:0

MOV

Initialize NT4

11

Rung 2:1

Channel 0

Status

] [

I:3.4

Rung 2:2

SCL

SCALE

Source N11:23

Rate [/10000]

Offset

Dest

The Rate and Offset parameters should

be set per your application. The Dest

will typically be an analog output chan-

nel. Refer to your programming device's

user manual or Analog I/O Modules

User Manual for specific examples of

the SCL instruction.

Rung 2:3

END

PID

Data Table

address 15 data 0 address 15 data 0

N10:0 0000 1000 0010 0001