Applying a reference to the desired input(s) – Rockwell Automation 1794-IT8,D17946.5.7 Thermocouple/Millivolt Input Module User Manual

Page 45

6–3

Calibrating Your Module

Publication 1794-6.5.7 – April 1997

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13 14

15

0

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

34

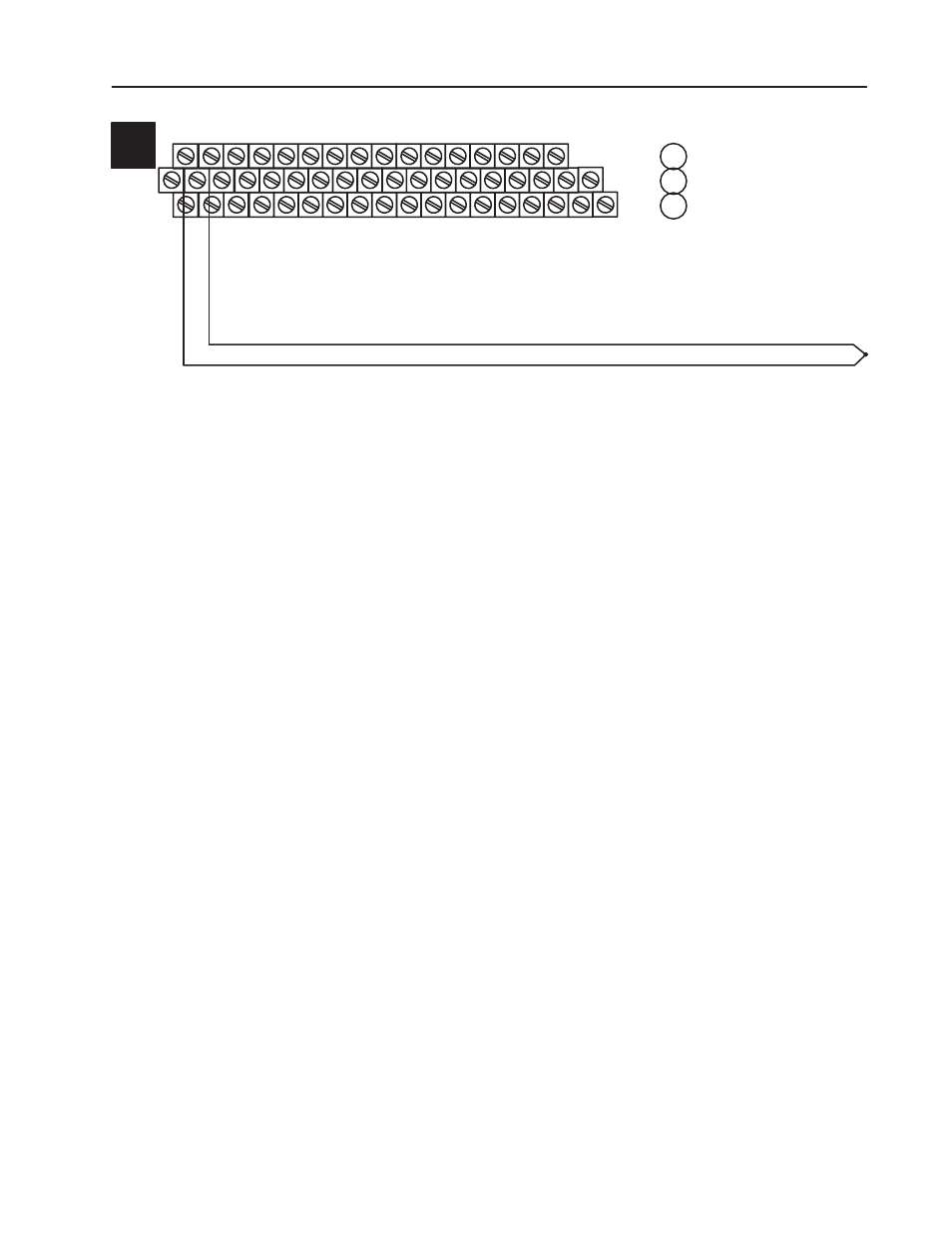

1794-TB3, -TB3T

0 –15

34–51

16–33

A

B

C

3

Thermocouple

or

Sensor

a. Remove the decade box and voltage source.

b. Reconnect the lead wires to the input terminals for this channel.

c. Repeat this procedure for the remaining channels.

You must calibrate the module in a FLEX I/O system. The module

must communicate with the processor and a programming terminal.

You can calibrate input channels in any order, or all at once.

Before calibrating your module, you must enter ladder logic into the

processor memory, so that you can initiate BTWs to the module, and

read inputs from the module.

Important:

In order to allow the internal module temperature to

stabilize, energize the module for at least 40 minutes

before calibrating.

Module calibration consists of:

•

Applying a reference to the desired input(s).

•

Sending a message to the module indicating which inputs to read

and what calibration step is being performed (offset).

The module stores this input data.

•

Applying a second reference signal to the module, and sending a

second message indicating which inputs to read and what

calibration step is being performed (gain).

The module computes new calibration values for the inputs.

Once the calibration is complete, the module reports back status

information about the procedure.

The following flow chart shows the procedure for calibration

Important:

Perform the offset calibration procedure first, then the

gain calibration procedure.

Manually Calibrating your

Thermocouple/mV Input

Module