Wiring of master module, Control power, Voltage and current inputs – Rockwell Automation 1403-DM_LM_MM Powermonitor II Instruction Sheet User Manual

Page 14

2-2

Installation

1403-IN001A-US-P

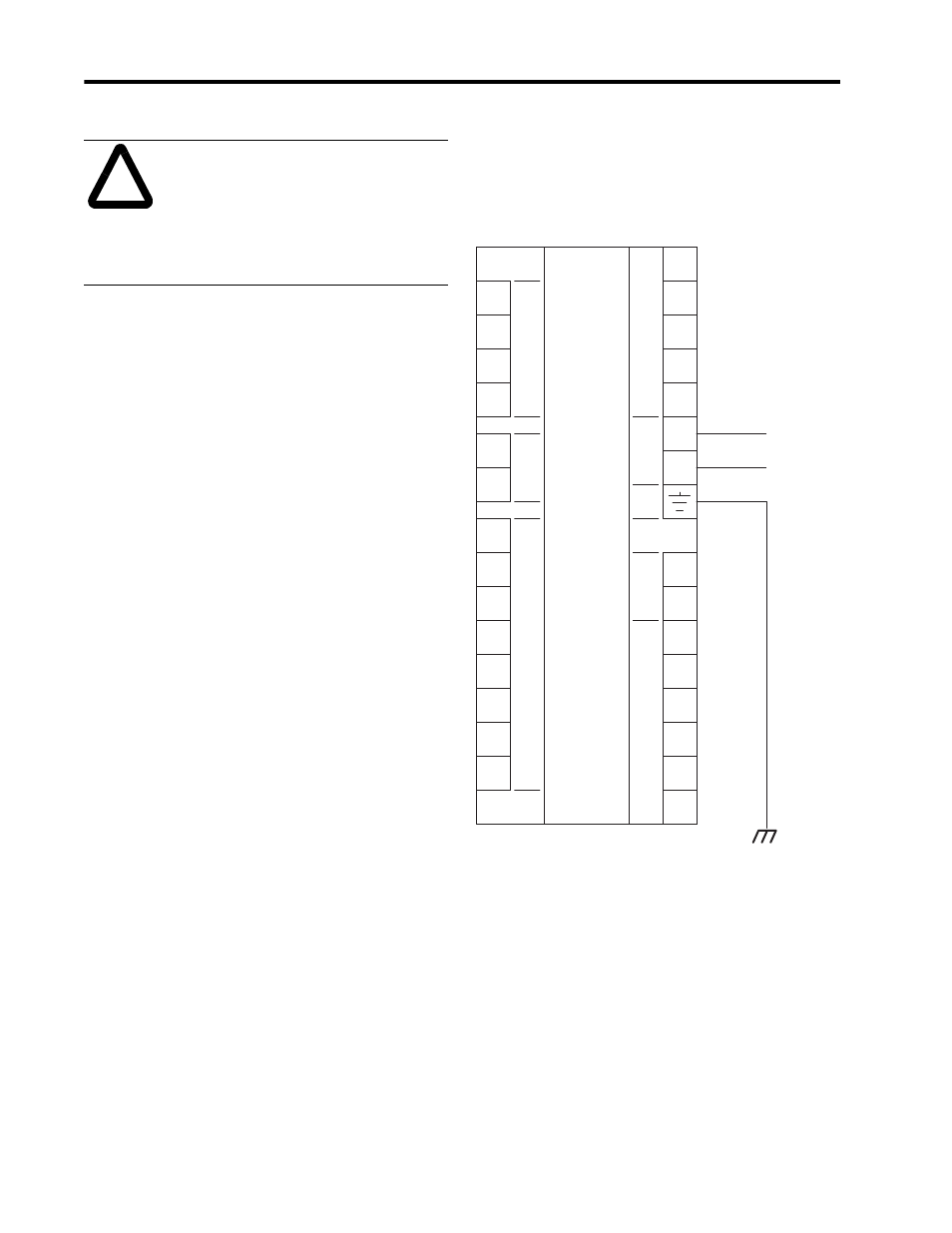

Wiring of Master Module

Terminal Blocks Wire Sizes and Screw Torques

Observe all wire lug sizes and screw torques. Refer to

Appendix C, Specifications.

Chassis Grounding

Electrically bond the Master

Module to the wiring installation via a bonding

terminal. Refer to Technical Specifications,

Appendix C. This protective earthing terminal shall

have no other function per local codes (ground bond

≥

largest measured conductor size). All ground wires

should be kept as short as possible; 30cm (12 in.) or

less is suggested.

Control Power

The power required by the Master Module is less

than 25VA to facilitate retrofit applications, but the

terminal block connections accept up to #12 AWG

(4 mm

2

) wire with lugs. The Master Module can be

powered directly from a local branch circuit. It

should be fused per local code.

Figure 2.1 Bulletin 1403-XMXX

Voltage and Current Inputs

Voltage Input and Potential Transformer (PT) Selection

All Bulletin 1403-xM Powermonitor II devices

handle direct connection for line to neutral voltages

of 120, 277, and 347 (line to line voltages of 208,

480, and 600V, respectively).

!

ATTENTION: Failure to comply

with these mounting requirements

may cause damage to the Display

Module or compromise the IP65

[NEMA/UL 508, Type 4X (Indoor)]

degree of protection per International

Standard IEC 529.

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

I2+

I3+

I4+

S1

S2

S3

S4

Scom

L/+

R14

R11

R12

R24

R21

R22

Acom

Ain

Cat. No. 1403-xMXXA

120/240 AC 50/60 HZ

125/250 DC

Cat. No. 1403-xMXXB

24 AC 50/60 HZ

12/24 DC

Voltage

Inputs

Status

Inputs

Display

Module

Fiber

Power

GRD

N/-

PM-II

Master

Module

L1

N/L2

Analog

Input

Current

Inputs

I1-

I2-

I3-

I4-

Relay

Outputs

Local Frame

Ground