Figure 3.24, Example for t6x, Applications – Rockwell Automation 825 Smart Motor Manager User Manual User Manual

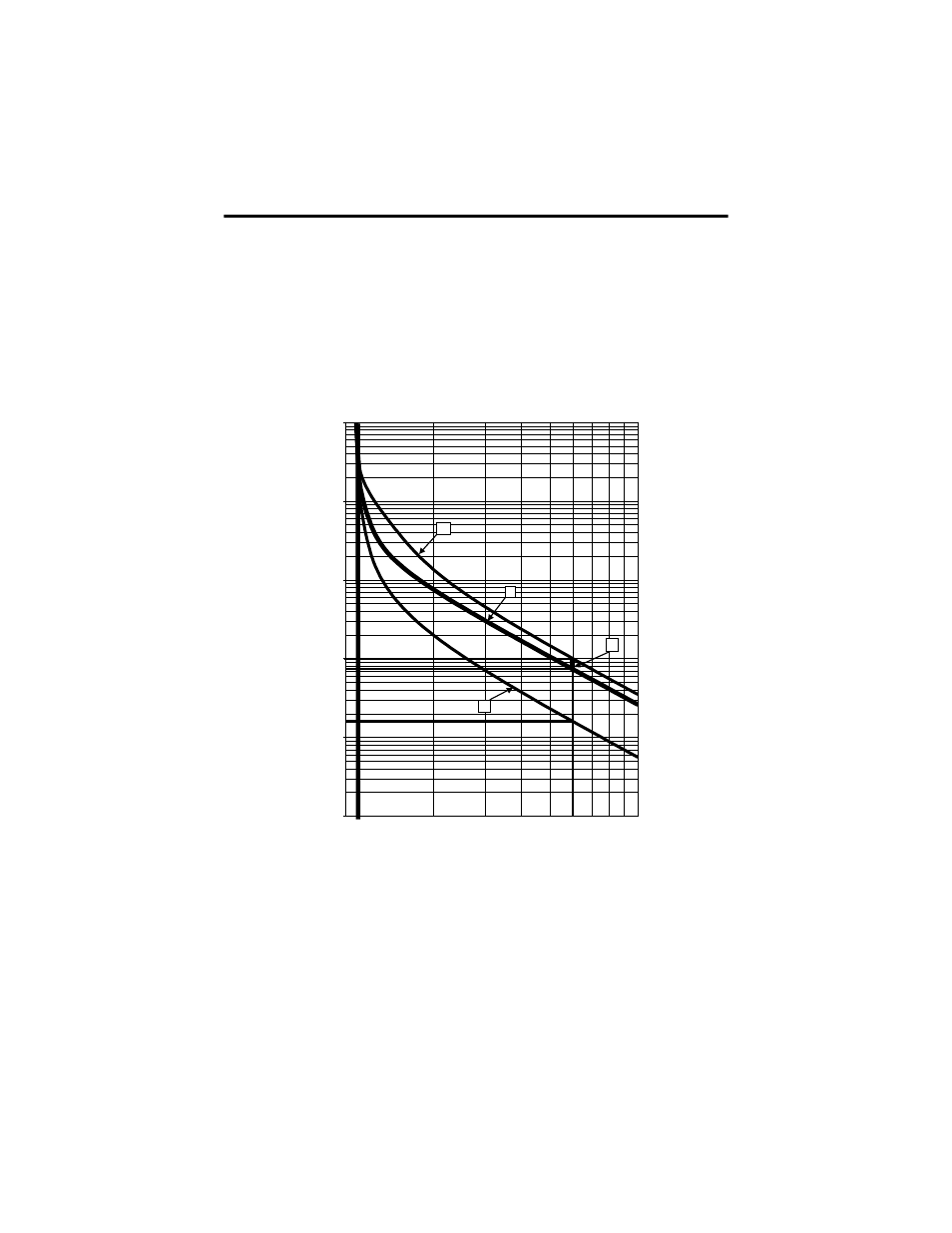

Page 70: Figure 3.24 example for t6x, 10 s and warm trip time = 70

3-37 Functions

Publication 825-UM001B-EN-P January 2001

Applications

•

The Warm Start function can be used in any installation that may have to be re-started

immediately after a voltage interruption.

•

Chemical process and production plants (e.g., mixers, centrifuges, pumps, conveyor

systems)

•

Mines and tunnels (fresh air fans, water pumps)

Figure 3.24 Example for t6x

,

e

= 10 s and Warm Trip Time = 70%

Load Current as Multiple of Full Load Current

T

rip Time

[s]

0.1

1.0

10.0

1.0

nx

I

1.6

a

b

c

7.3

d

10

4

10

3

10

2

e

5

10.0

9

8

7

6

4

3.0

2.0

1.1

a) Time/current characteristic from cold when setting the trip time t6x

,

e

= 10 s.

b) Time/current characteristic after preloading with 1x

,

e

when the trip time from cold t6x

,

e

= 10 s and WARM START function is

disabled.

c) Time/current characteristic after preloading with 1x

,

e

(thermal utilization or winding temperature = 82%) when the trip time

from cold t6x

,

e

= 10 s and WARM START function is enabled, setting: WARM TRIP TIME = 70% of the trip time from cold.

(The WARM TRIP TIME 7.3 s for 6x

,

e

is higher than (70% x 10) = 7 s because it depends on the winding and iron temperature

which are not at their highest value.)

d) If the thermal utilization (winding temperature) is higher than 82%, the WARM START function is automatically disabled. If

lower than 82% the WARM TRIP TIME depends on the winding and iron temperature and its range is 7.3…10 s.