Table 3.p, Table 3.q – Rockwell Automation 825 Smart Motor Manager User Manual User Manual

Page 62

3-29 Functions

Publication 825-UM001B-EN-P January 2001

Application

•

High-voltage motors

•

Installations in a difficult environment, with moisture, dust, etc. (e.g., mines, gravel

pits, cement factory, mills, woodworking shops, water pumping stations, waste water

treatment)

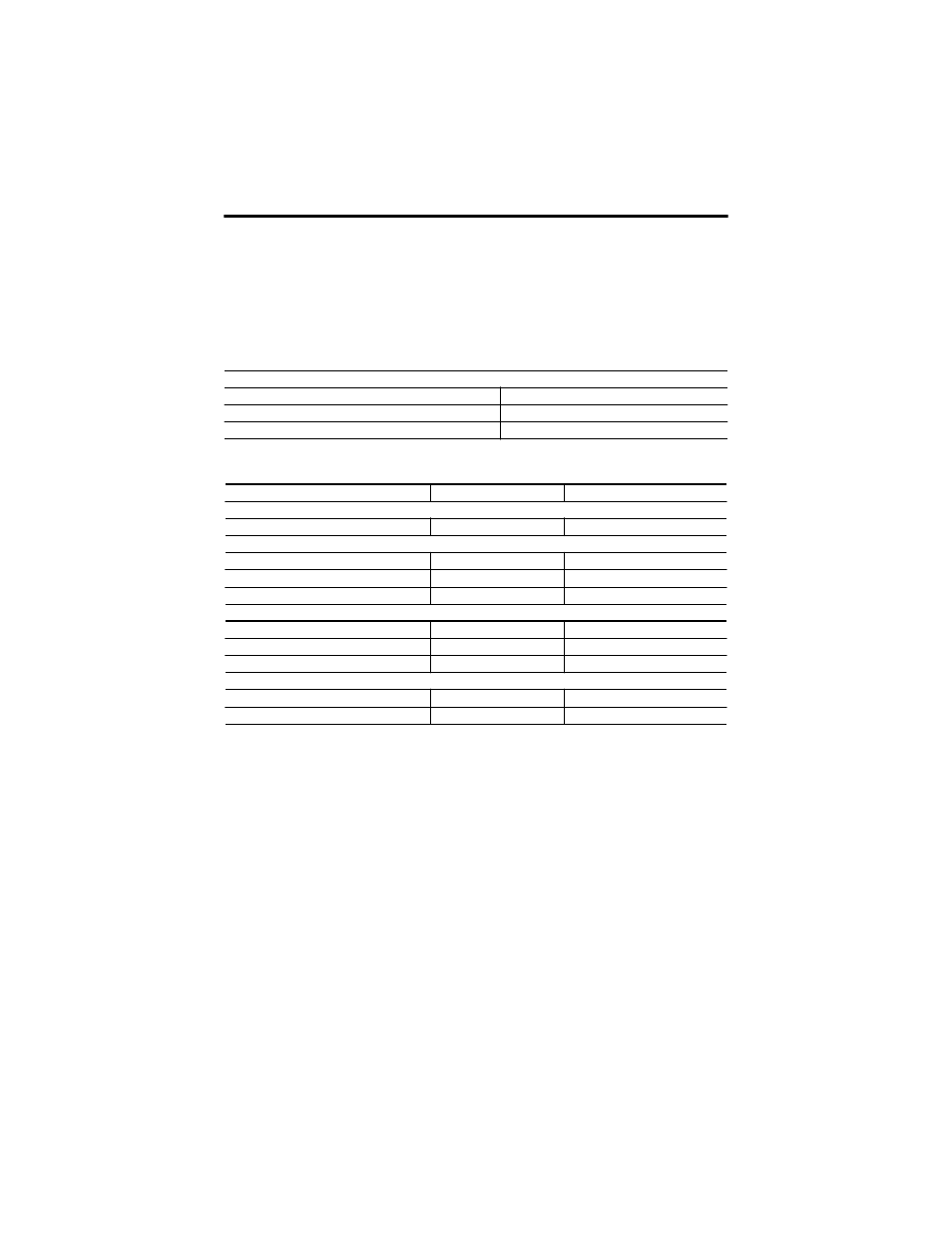

Table 3.P Core Balance Current Transformer Setting Parameters

Table 3.Q Earth (Ground) Fault Core Balance Setting Parameters

➊ –5…60

°

C (23…140

°

F)

➋ If auxiliary relays #2 and #3 are assigned to the communication (refer to page

) they cannot be selected

here.

Earth (Ground) Fault Protection in High-Voltage Systems

This section provides an overview of earth (ground) faults in isolated, high-impedance earth,

or compensated networks.

With earth neutral point-type networks, the magnitude of the earth (ground) fault (leak)

current is determined by the earth capacitance of the network and the earth resistance or the

compensating reactor. Because the size of industrial networks is limited, earth fault currents

are very small. To a great extent, earth capacitances are determined by the cables and the

motors.

The capacitance values for cables are given in cable tables and range from approximately

0.2…1.2

µ

F/km. A value between 0.02…0.05

µ

F per MW of motor rating can be assumed

for high-voltage motors.

Current Ratio

Setting range

1…2 000

Factory setting

100

Setting steps

1

Warning ➊

Trip ➊

Function

Factory setting

Off

On

Response Level

Setting range

5 mA…50 A

5 mA…50 A

Factory setting

500 mA

1.0 mA

Setting increments

5 mA

0.25 A

Tripping Delay

Setting range

—

0.1…5 s ± 0.04 s

Factory setting

—

0.5 s

Setting increments

—

0.1 s

Output Relay ➋

Selection (relays)

AL, #1…#5

MR, AL, #1…#5

Factory setting

AL

MR