Rockwell Automation 825 Smart Motor Manager User Manual User Manual

Page 136

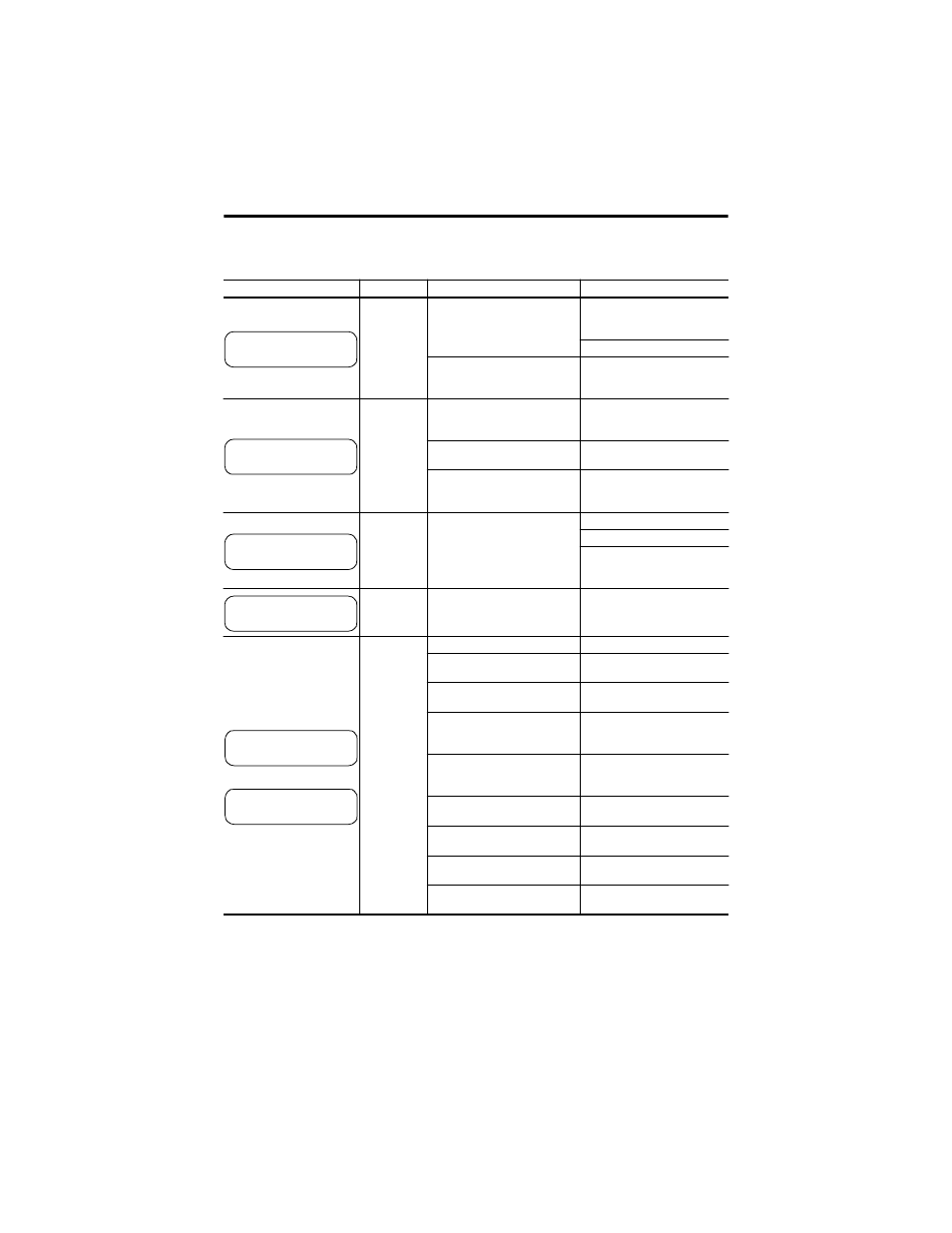

8-4 Error Diagnosis and Troubleshooting

Publication 825-UM001B-EN-P January 2001

Table 8.A Possible Causes and Actions (Continued)

LCD

Designation

Possible Causes

Actions

Converter

module cannot

be correctly

recognized

Link between basic unit and

converter module defective

Check link between basic unit

and converter module and

replace if necessary.

Switch supply off and on again

Fault in basic unit

If the fault cannot be remedied,

send the unit back to the factory

for repair.

Rated current

and setting do

not agree

Converter module rated current

does not agree with basic unit

setting

Check setting “FULL LOAD

CURR” and converter module.

Wrong converter module

Install the correct converter

module

Wrong setting

Press “Values” until “SET

Values” on LCD, correct “FULL

LOAD CURR” (within about 5 s)

Error in actual

values

Data could not be saved when

supply last interrupted

Press Reset.

Check power supply.

If the fault repeatedly occurs,

send the unit back to the factory

for repair.

—

Hardware fault

Send the basic unit back to the

factory for repair.

Thermal

warning

Thermal trip

Overloaded

Reduce load.

Transported material jammed

Switch off installation, remedy

trouble.

Mechanical damage,

bearings, etc.

Repair the damage.

Settings of rated current or

tripping time too low

Raise “FULL LOAD

CURR”/”LOCKED ROT TIME” to

permissible motor values.

Interrupted start: motor

inadequately cooled

Wait until motor has cooled

down. (LCD: TH UTIL…% appr.

20%)

More than one warm start/hour

If permissible, increase

number of warm starts/h.

Ambient temperature too high

(Function PT100, #7 ON)

If possible, reduce load.

Very high third harmonic

(e.g., star-delta connection)

Raise

,

e

setting accordingly.

Cooling constant ratio has been

changed

Check and reset to correct

setting (factory setting 2.5).

825-MCM ERROR

IE OUT OF RANGE

ERROR ACT VALUES

ERROR REC VALUES

THERMAL WARNING

THERMAL TRIP