Rockwell Automation 825 Smart Motor Manager User Manual User Manual

Page 139

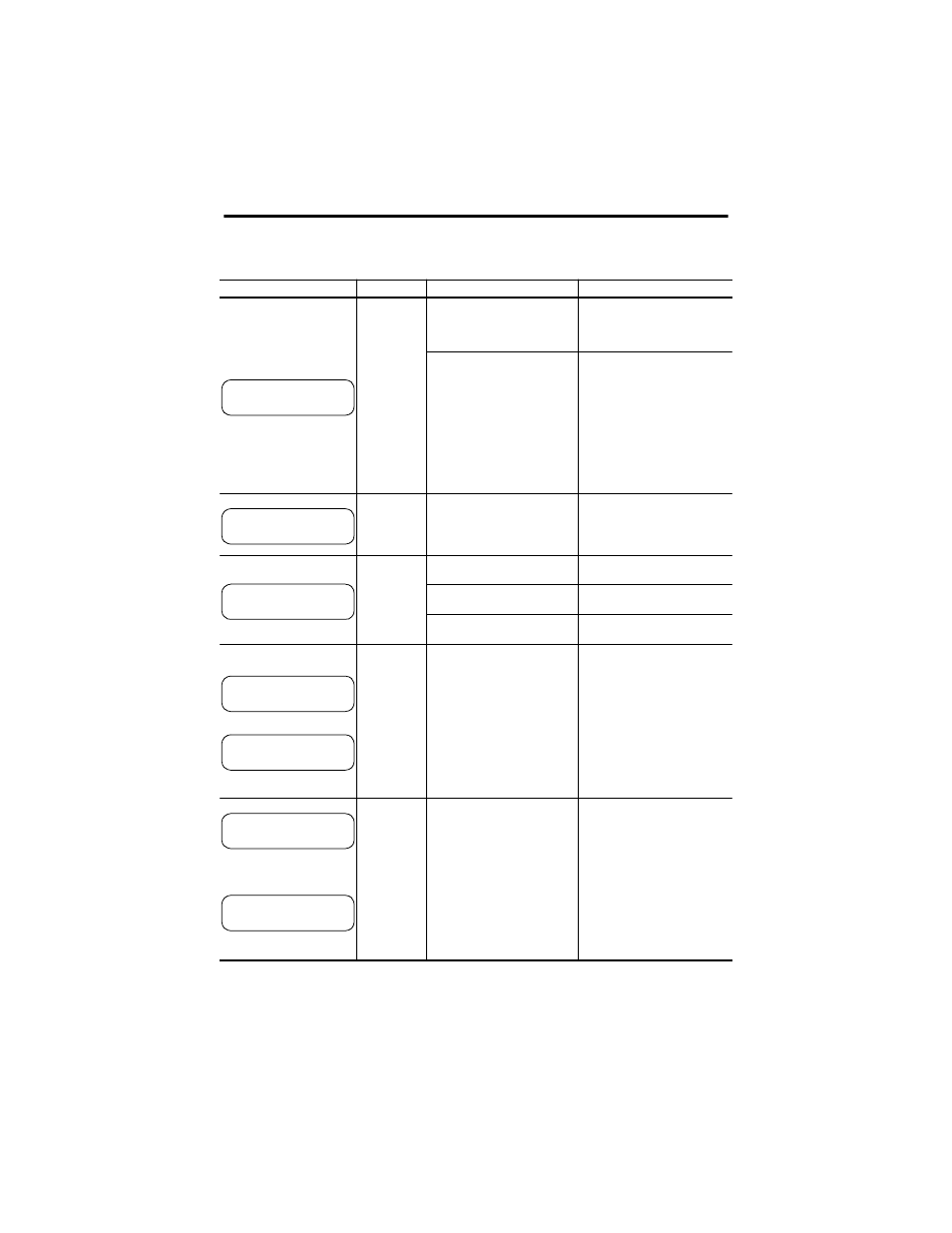

Error Diagnosis and Troubleshooting 8-7

Publication 825-UM001B-EN-P January 2001

Table 8.A Possible Causes and Actions (Continued)

LCD

Designation

Possible Causes

Actions

PTC trip

PTC or PTC leads short-circuited

or broken

Check leads, remove fault. PTC:

Motor for repair. If not possible,

switch off PTC monitoring “PTC

PROT/OFF“.

Stator winding overheated by:

•

Overload

•

Too many starts/hour

•

Too many warm starts/hour

•

Obstructed cooling

•

High ambient temperature

Wait until motor has cooled down

sufficiently for a reset.

•

Search for cause and

eliminate.

•

Reduce starts/hour.

•

Reduce number of warm

starts/hour.

•

Clean motor and cooling air

intake.

•

Protect against heat; reduce

load or switch off installation.

Phase

sequence

protection

(motor supply)

Wrong phase sequence of supply

to converter module

Connect phase leads in correct

sequence.

Phase failure

trip

(based on

motor supply)

Faulty fuse:

Short-circuit/earth (ground) fault

Remedy damage, replace the

fuse.

Failure during start

Redimension fuse (noting

short-circuit coordination).

Broken lead

Check cables and terminal

connections.

PT100 #1…#6

(RTD)

temperature

warning

PT100 #1…#6

(RTD)

temperature

trip

Stator winding overheated by:

•

Overload

•

Too many starts/hour

•

Too many warm starts/hour

•

Obstructed cooling

•

High ambient temperature

Wait until motor has cooled down

sufficiently to permit reset.

•

Search for cause and remedy.

•

Reduce start/hour

•

Reduce warm starts/hour

•

Clean motor and cooling air

intake.

•

Protect against heat. Reduce

load or shut down the

installation, and wait until

motor has cooled down

sufficiently for a restart.

PT100 (RTD)

has been

short- or open-

circuited.

This message

may appear

together with a

PT100 #1…#6

(RTD) TRIP

Failure in PT100 (RTD) circuit

Check cables, terminal connection

and PT100 (RTD) sensor

PTC TRIP

PHASE REVER TRIP

PHASE LOSS TRIP

PT100 #…WARNING

PT100 #…TRIP

PT100 SHORT CIRC

PT100 NO CONNECT