Troubleshooting, Problem corrective action – Rockwell Automation 160 SER A FRN 1.XX-4.XX User Manual

Page 39

Chapter 6 - Troubleshooting and Fault Information

6–3

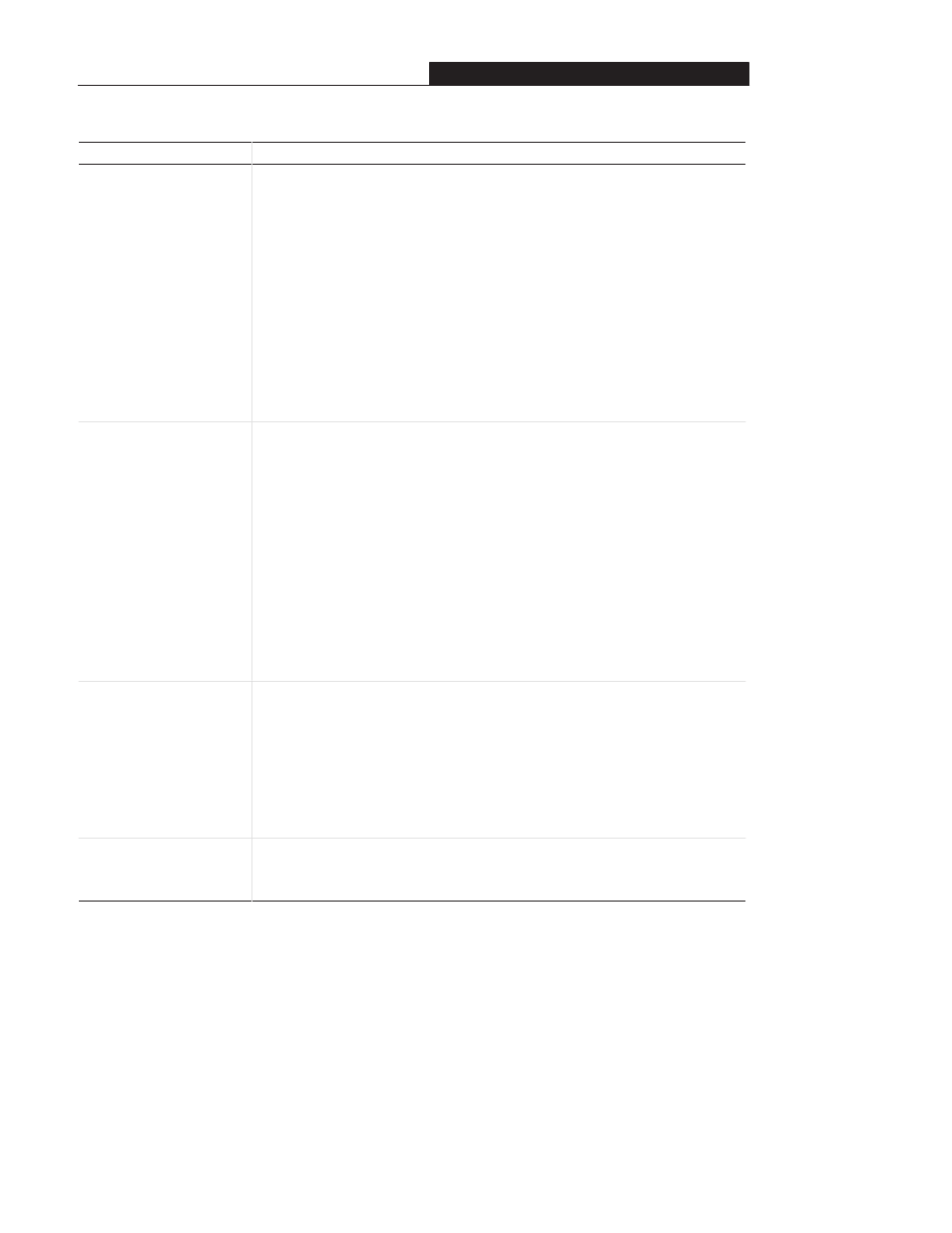

Table 6.B Troubleshooting

Problem

Corrective Action

Motor does not start

(No output voltage to motor).

1. Check power circuit.

D Check supply voltage.

D Check all fuses and disconnects.

2. Check motor.

D Verify that motor is connected properly.

3. Check control input signals.

D Verify that START signal is present.

D Verify that STOP signal is present.

D Verify that RUN FORWARD and RUN REVERSE signals are NOT both active.

4. Check P46 - [Input Mode Select].

D If P46 - [Input Mode Select] is set to 2", only the program keypad module Start button will start

the motor.

Controller Started but motor

NOT rotating.

(P01 - [Output Frequency]

displays 0.0").

1. Check motor.

D Verify that motor is connected properly.

2. Check frequency source P06 - [Frequency Command].

D Verify that frequency signal is present at terminal block TB3.

-10Ć +10V signal

4-20 mA signal

D Verify that Preset Frequencies are set properly.

3. Check control input signals.

D Verify that SW1, SW2 and SW3 are correct. (Refer to the chart at the end of Chapter 5).

4. Check parameter settings.

D Verify that P59 - [Freq Select] is showing desired frequency source.

D Verify that P58 - [Internal Frequency] is the desired value.

Motor not accelerating properly.

1. Check motor.

D Verify that motor is connected properly.

D Verify that no mechanical problems exist.

2. Check parameter settings.

D Verify that P30 - [Accel Time 1] or P69 - [Accel Time 2] is set properly.

D Verify that P43 - [Current Limit] is set properly.

D Verify that P38 - [Boost Volts] is set properly.

Can not operate in RUN FWD/

RUN REV" mode.

1. Verify that P46 - [Input Mode Select] is set to 1".

2. Verify that power has been cycled for above change to take effect.

3. Verify that both RUN FORWARD and RUN REVERSE switches are NOT closed simultaneously.