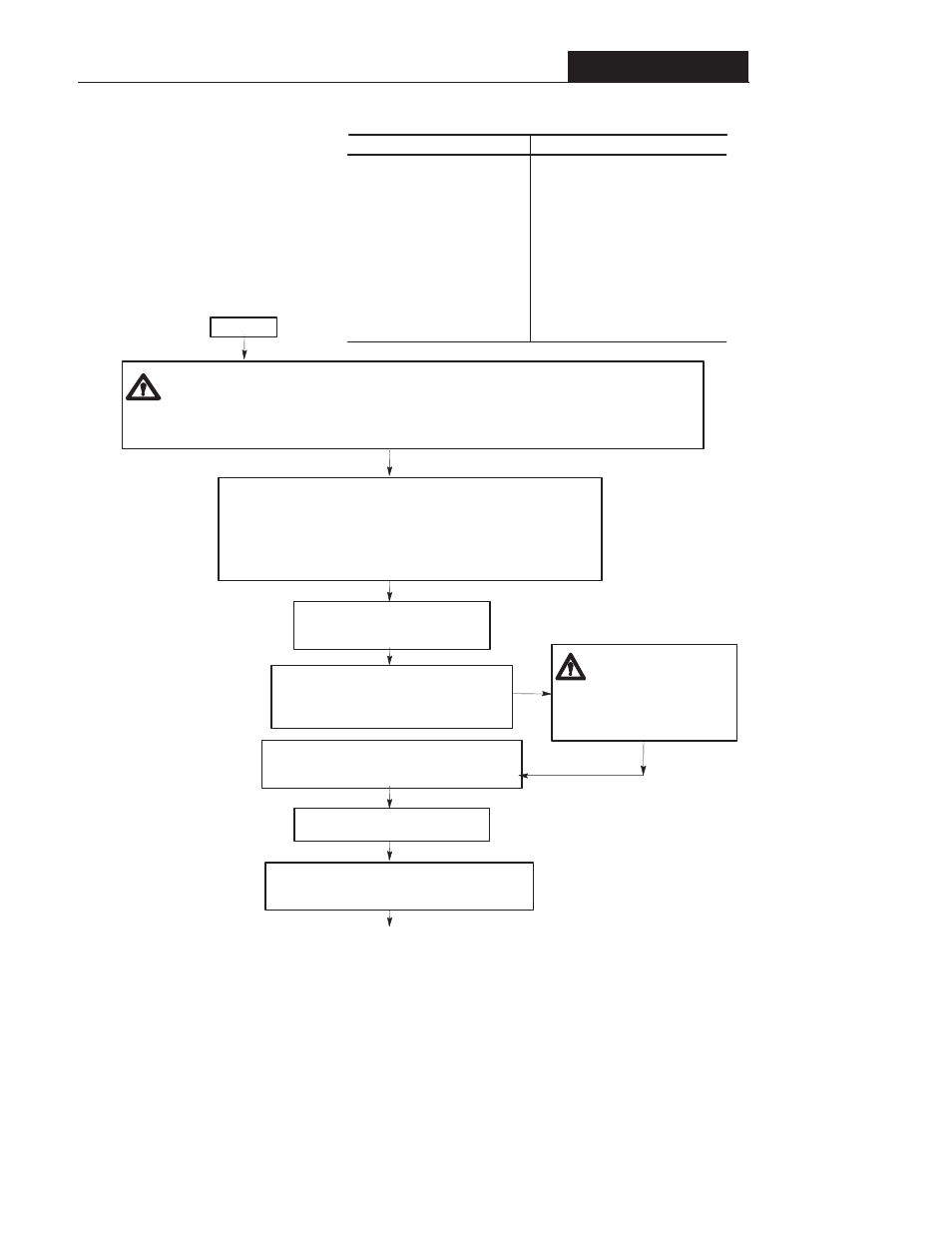

Chapter 4 - start-up, Start-up procedure (analog signal follower model), Start-up procedure (preset speed model) – Rockwell Automation 160 SER A FRN 1.XX-4.XX User Manual

Page 25: Start–up procedure (analog signal follower model), Start–up procedure (preset speed model), Start-up, Chapter

4

Chapter

Start-Up

4–1

Verify that AC line power at the

disconnect device is within the rated

value of the controller.

Disconnect and lock out all incoming power to

the controller including incoming AC power to

terminals L1, L2 and L3 (R, S and T) of power

terminal block TB1.

Verify that the motor leads are connected to the

power terminal block TB2, terminals T1, T2, T3 (U,

V, W).

Verify that the STOP input is present

at the TB3 control terminal block.

Confirm that all other control inputs are connected to

the correct terminals and are secure. GO TO THE

NEXT PAGE.

ATTENTION:

A DC Bus

voltage may be present at the

power terminal blocks (TB1)

and (TB2) for approximately

one minute after power is

removed from the controller.

D

Minimum clearance distance between controller and other equipment.

D

Proper grounding practices have been followed.

D

Proper power and control wiring has been used.

Start-Up Checklist

Verify the controller is installed per instructions outlined in Chapter 2 including:

P30-[Accel Time 1]

P31-[Decel Time 1]

P33-[Maximum Frequency]

P34-[Stop Mode Select]

P35-[Base Frequency]

P36-[Base Voltage]

P42-[Motor Overload Current]

P46-[Input Mode]

P47-[Output Configure]

Preset Speed Model Only

P61-P68-[Preset Frequency 0-7]

Chapter 5 provides a comprehensive description of

all controller parameters. Review the factory default

settings. If your controller is equipped with a ProĆ

gram Keypad Module these parameters can be

changed to meet your specific application requireĆ

ments. An example of how to program a parameter

is shown at the beginning of Chapter 5.

ATTENTION:

Power must be applied to the controller to perform the following startĆup procedure. Some of

the voltages present are at incoming line potential. To avoid electric shock hazard or damage to equipment, only

qualified service personnel should perform the following procedure. Thoroughly read and understand the

procedure before beginning. If an event does not occur while performing this procedure, Do Not Proceed.

Remove Power by opening the branch circuit disconnect device and correct the malfunction before continuing.

desired accel time.

desired decel time.

maximum frequency required.

desired stopping mode.

motors rated nameplate frequency.

motors rated nameplate voltage.

motor nameplate Full Load Amps [FLA].

desired control method.

desired output functionality.

desired preset frequencies.

Parameter

Set to...

Commonly Changed Parameters

Start Here

A