2160 ssc™ variable speed controller (series b), Figure 1 recommended grounding configuration – Rockwell Automation 160 SER A FRN 1.XX-4.XX User Manual

Page 10

160_5_9DU2.doc 2 Mon Sep 15 11:42:00 1997

2

160 SSC™ Variable Speed Controller (Series B)

General Instructions for an

EMC Compliant Installation

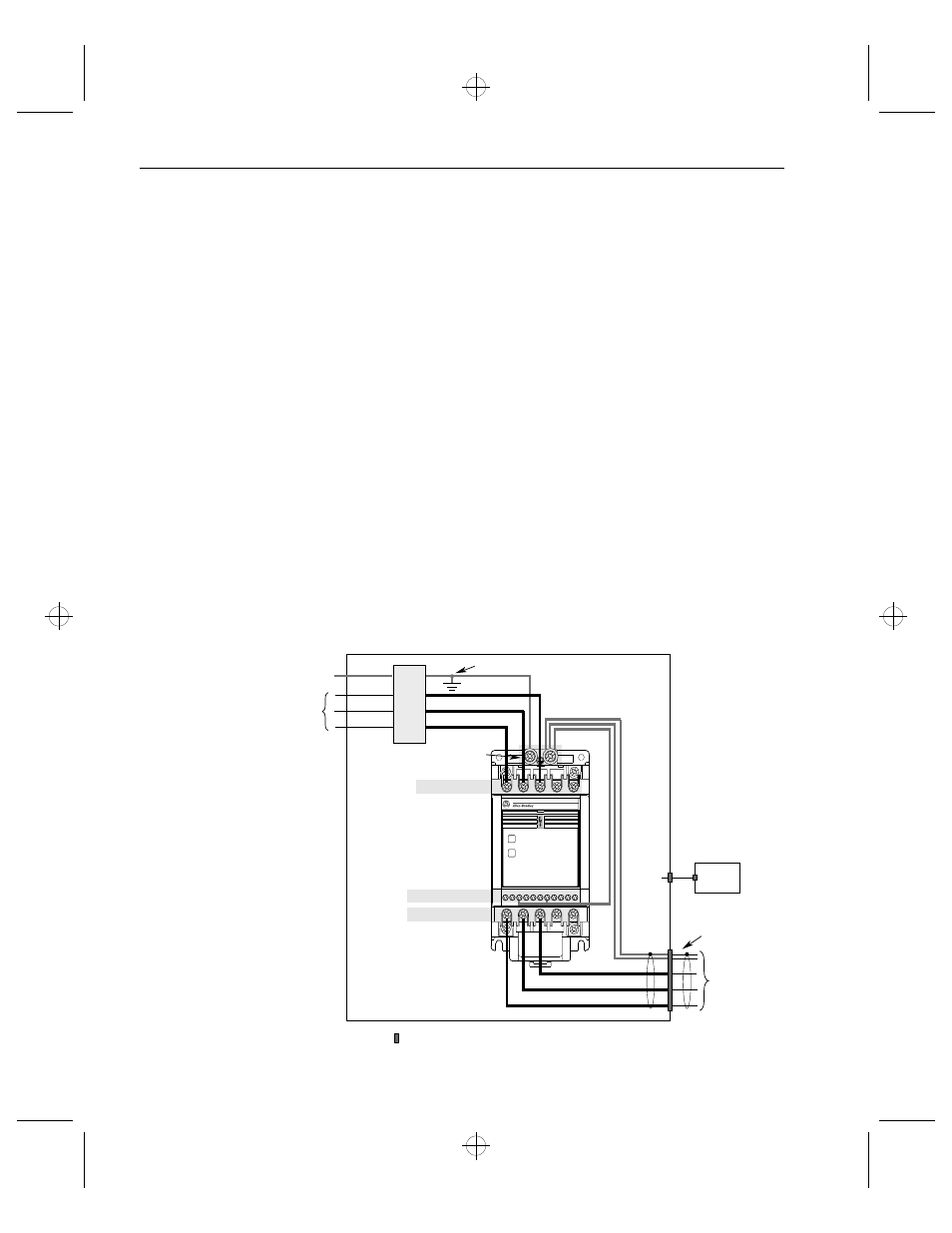

Refer to Figure 1.

Shielded Enclosure

• Typical NEMA or IEC metal enclosures are adequate.

• The ground connection of the shielded enclosure must be solidly

connected to the PE terminal of the controller. Good conductivity

must be assured – grounding must provide a low impedance path

to high frequency signals.

• All wiring, except input power leads, must use shielded cable.

• Input power, output power and control wiring inside the enclosure

must be physically separated.

• Input power, output power and control wiring outside the enclosure

must use separate shielded cables, or separate conduit.

Cable Clamps

• Use suitable EMC-tested cable clamps only.

• The connection area must be 360 degrees around the shielded cable.

• The cable clamps also provide strain-relief for the cable.

• When using conduit, the contact point of metal entry connections

must be free of paint or non-conductive surfaces and solidly

connected with good conductivity to the enclosure.

Figure 1 Recommended Grounding Configuration

R (L1)

S (L2)

T (L3)

PE

AC

Input Line

Shielded Enclosure

Enclosure Ground Connection

U (T1)

Shielded Motor Cable

to TB3

Control

Cabinet *

to Motor

V (T2)

W (T3)

R (L1)

S (L2)

T (L3)

= EMC Tested Shielded Cable Clamp (or Metal Conduit)

* When the control circuitry is located outside of the 160 enclosure.

Control Wiring TB3

Motor Wiring TB2

L2

S

L1

R

L3

T

BR

–

BR

+

1 2 3 4 5 6 7 8 9 10 11

T2

V

TI

U

T3

W

–

DC

+

DC

Ground Tab – PE

Line Power TB1

FAULT

READY

Line

Filter