Original instructions, 3 indications and error messages – Rockwell Automation 442L SafeZone Singlezone & Multizone Safety Laser Scanner User Manual

Page 42

R

SafeZone™ Safety Laser Scanner User Manual

40 10000073050, July 2011

Original instructions

² If possible use anti-static floor mats and workbench covers.

² When working on the SafeZone safety laser scanner, touch a bare metal

surface from time to time to discharge static charging of your body.

² Only remove the components for the SafeZone safety laser scanner from

their anti-static packing immediately prior to installation.

² Note that no liability can be accepted for damage caused by electrostatic

discharge.

Replacing the I/O module:

² Disconnect the system connector and remove the SafeZone safety laser

scanner.

² Take the SafeZone safety laser scanner to a clean place (office, repair

shop or similar).

² First clean the outside of the SafeZone safety laser scanner.

This prevents foreign bodies entering the device when it is opened.

² Undo the mounting screws for the I/O module.

² Take hold of the I/O module with one hand at the recess for the

connector to the system connection.

² With the other hand take hold of the I/O module at the dismantling aid

on the underside of the device.

² Pull out the I/O module parallel to the mounting shaft.

² Remove any contamination from the sealing surface and the mating

surface for the sensor head. For this purpose if possible use a plastic

cleaner that does not leave residues (see Section 12.2 “Accessories/spare

parts” on page 53).

² Remove the I/O module from the packaging, ensure that you take

adequate ESD protection measures during this process.

² Check the surfaces for cleanliness and the seal for correct seating.

² Insert the I/O module in the mounting shaft parallel to the rear of the

sensor head. During this process use the three surrounding sides of the

shaft for orientation.

² Guide the I/O module along these surfaces to the connector. During

this process slide the I/O module parallel to the rear of the sensor, avoid

tilting. The I/O module can be connected without the need to apply

force.

² When the I/O module is flat against the rear of the sensor head

(distance approx. 1 N

•m or 8.9 in•lbf ), tighten the screws in stages,

diagonally (to 10…12 N

•m or 88.5…106 in•lbf).

Re-commissioning the SafeZone safety laser scanner:

² Correctly re-mount the SafeZone safety laser scanner (see Section 4

“Installation and mounting” on page 18).

² Connect the SafeZone safety laser scanner system connector.

After power up the SafeZone safety laser scanner

automatically reads the saved configuration from the

system connector (see Section 8.3 “Re-commissioning”

on page 37).

Section 10 — Diagnostics

This section describes how to identify and remedy errors and

malfunctions during the operation of the safety laser scanner.

10.1 In the event of faults or errors

10.2 Rockwell Automation Support

If you cannot remedy an error with the help of the information provided

in this section, please contact your local Rockwell representative or

technical support.

10.3 Indications and error messages

This section describes the meaning of the indications and error messages

and how you can respond. You will find a description of the indicators in

Section 3.5 “Indicators and outputs” on page 17, the connections for the

outputs in Section 5.1 “System connection” on page 31.

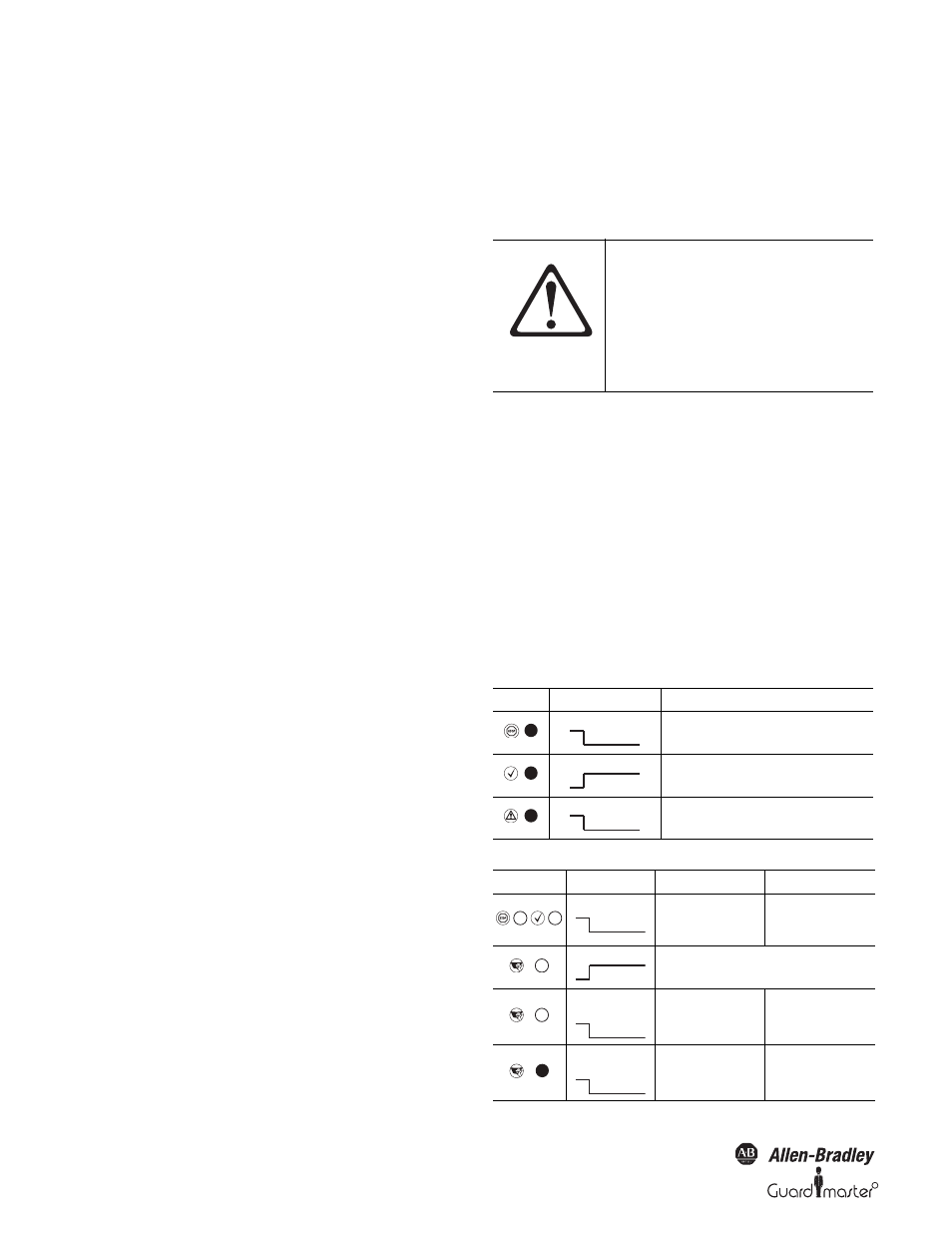

ATTENTION

If a fault or error is observed, cease

operation if the cause of the

malfunction has not been clearly

identified.

Stop the machine, the system or the

vehicle if you cannot clearly identify or

allocate the error and if you cannot

safely remedy the malfunction.

Display

Output Level

Possible Cause

At the OSSDs

Object in the protective safety field, OSSDs

deactivated

At the OSSDs

Protective safety field unoccupied, OSSDs activated

At the warning field output

Object in warning field

Display

Output Level

Possible Cause

Remedying the Error

OSSDs

No operating voltage, or

voltage too low

² Check the voltage

supply and activate, if

necessary.

Error/contamination

No error

Application

diagnostic output

No supply voltage

² Check the voltage

supply and activate, if

necessary.

Application

diagnostic output

Front screen

contaminated, operation

not

² Clean the front screen.