1 cleaning the front screen, 2 replacing the front screen – Rockwell Automation 442L SafeZone Singlezone & Multizone Safety Laser Scanner User Manual

Page 40

R

SafeZone™ Safety Laser Scanner User Manual

38 10000073050, July 2011

Original instructions

Section 9 — Care and maintenance

9.1 Cleaning the front screen

The SafeZone safety laser scanner is maintenance-free. The front screen

on the safety laser scanner should however be regularly cleaned and also

if contaminated:

• Do not use aggressive detergents.

• Do not use abrasive cleaning agents.

Cleaning the front screen:

² Use a clean and soft brush to remove dust from the front screen.

² Next, wipe the front screen with a clean and damp cloth.

9.2 Replacing the front screen

If the front screen is scratched or damaged, you must replace it. Order the

replacement front screen from Rockwell (see Section 12.2 “Accessories/

spare parts” on page 53).

Replacement of the front screen:

² Disconnect the system connector and remove the SafeZone safety laser

scanner.

² Take the SafeZone safety laser scanner to a clean place (office, repair

shop or similar).

² First clean the outside of the SafeZone safety laser scanner. This

prevents foreign bodies entering the device when it is opened.

² Undo the mounting screws to for the front screen.

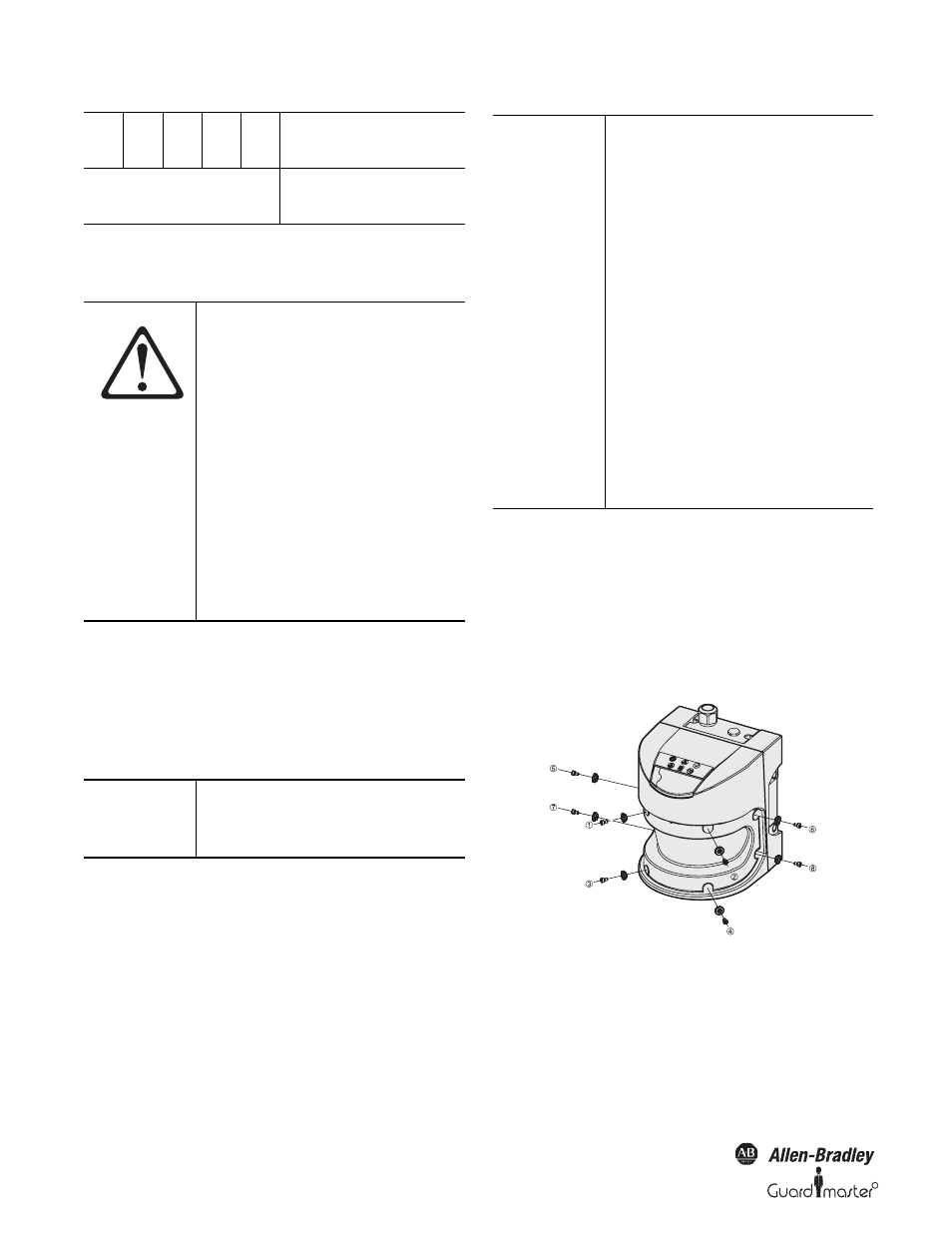

Figure 60: Removing the mounting screws for the front screen

²

Next, remove the old front screen and the old rubber seal.

² Remove any dirt from the seal groove and the mating face on the sensor

head. For this purpose if possible use a plastic cleaner that does not leave

residues (see Section 12.2 “Accessories/spare parts” on page 53).

l

l

m

m

m

Or:

The device is operational, no object in

protective safety field and warning field.

Other display

Safety lock activated. Malfunction in the

external conditions or in the device itself (see

Section 10.3 “Indications and error messages”

ATTENTION

Do not make any repairs to the device.

The SafeZone safety laser scanner does

not contain any repairable

components. For this reason do not

open the SafeZone safety laser scanner

components and only replace the parts

that are described in the following

sections as replaceable.

Switch the entire machine/system off

line.

The machine/system could

inadvertently start up while you are

changing the front screen. As a matter

of principle, always isolate the machine

from the power supply during all work

on the machine and safety laser

scanner.

IMPORTANT

Static charges cause dust particles to

be attracted to the front screen. You

can diminish this effect by using an

antistatic plastic cleaner.

IMPORTANT

²

The front screen on the SafeZone

safety laser scanner is an optical part

that must not be contaminated or

scratched.

²

The front screen is only allowed to

be replaced by specialist personnel

in a dust- and dirt-free environment.

²

Never replace the front screen

during operation as dust particles

could enter the device.

²

It is imperative that you avoid

contamination of the inside of the

front screen, e.g. with fingerprints.

²

Do not use any additional sealant for

sealing the front screen, e.g. silicon,

as the vapors produced may

damage the optics.

²

Mount the front screen as per the

following instructions to ensure that

the housing is sealed to IP65.

Recommendation

If necessary smear a thin coating of vaseline in

the seal groove. This makes mounting easier.