Original instructions – Rockwell Automation 442L SafeZone Singlezone & Multizone Safety Laser Scanner User Manual

Page 24

R

SafeZone™ Safety Laser Scanner User Manual

22 10000073050, July 2011

Original instructions

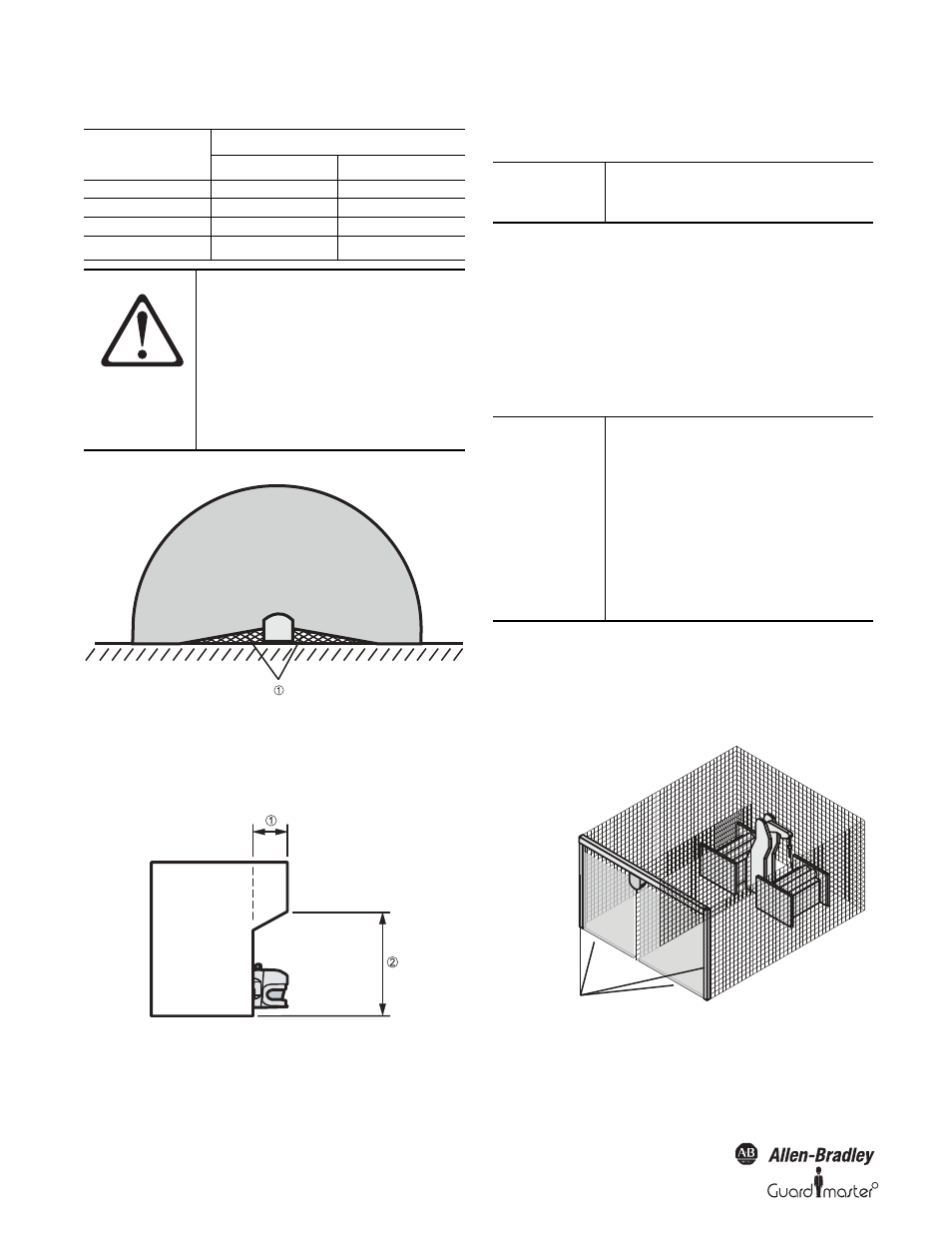

Table 10: Size of the unprotected areas

Mounting with hard guards

Figure 26: Example of mounting with hard guards

² Fit the hard guard such that the areas not covered by the safety laser

scanner are completely protected against personnel standing in them.

Mounting in a recess

Figure 27: Form of the recess

²

Design the recess

to be sufficiently deep enough that it

completely covers the area not protected by the safety laser

scanner (Figure 26) and such that standing in an unscanned area

is not possible.

4.2 Stationary Vertical Operation for Access

Protection

Access protection can be used when the access to the machine can be

defined by physical means. For access protection the SafeZone safety

laser scanner detects the entry of an entire body.

4.2.1 Safety distance

For access protection, a safety distance (S) must be maintained between

protective safety field and hazardous area. This safety distance ensures

that the hazardous point can only be reached after the dangerous state of

the machine has been completely stopped.

Figure 28: Access protection

Size of Unprotected Areas

Mounting Method

X

Y

Direct mounting

109 mm

618 mm

With mounting kit 1

112 mm

635 mm

With mounting kit 1 and 2

127 mm

720 mm

With mounting kit 1, 2 and 3

142 mm

805 mm

ATTENTION

Prevent unprotected areas.

Mount the SafeZone safety laser

scanner such that there are no

unprotected areas. Take one of the

precautions given in the following:

²

Install hard guards to prevent

standing behind.

²

Install the SafeZone safety laser

scanner in a recess.

IMPORTANT

Prevent crawling beneath the recess by

limiting the height of the recess such

that nobody can crawl beneath.

IMPORTANT

To ensure adequate access protection,

a response time of ~ 90 ms and a

resolution of 150 mm or finer is

required.

To protect the SafeZone multizone

scanner against inadvertent

adjustment or manipulation, use the

contour of the surrounding area as a

reference (see Section 3.4.3 “Using the

contour of the protective safety field as

a reference” on page 12).

Contours on the floor and the

side walls as reference