Original instructions, 3 replacing the i/o module – Rockwell Automation 442L SafeZone Singlezone & Multizone Safety Laser Scanner User Manual

Page 41

R

SafeZone™ Safety Laser Scanner User Manual

10000073050, July 2011 39

Original instructions

² Insert the new seal —starting in the middle. During this process first

align the center markings on the sensor head (

and ) and seal (

and

).

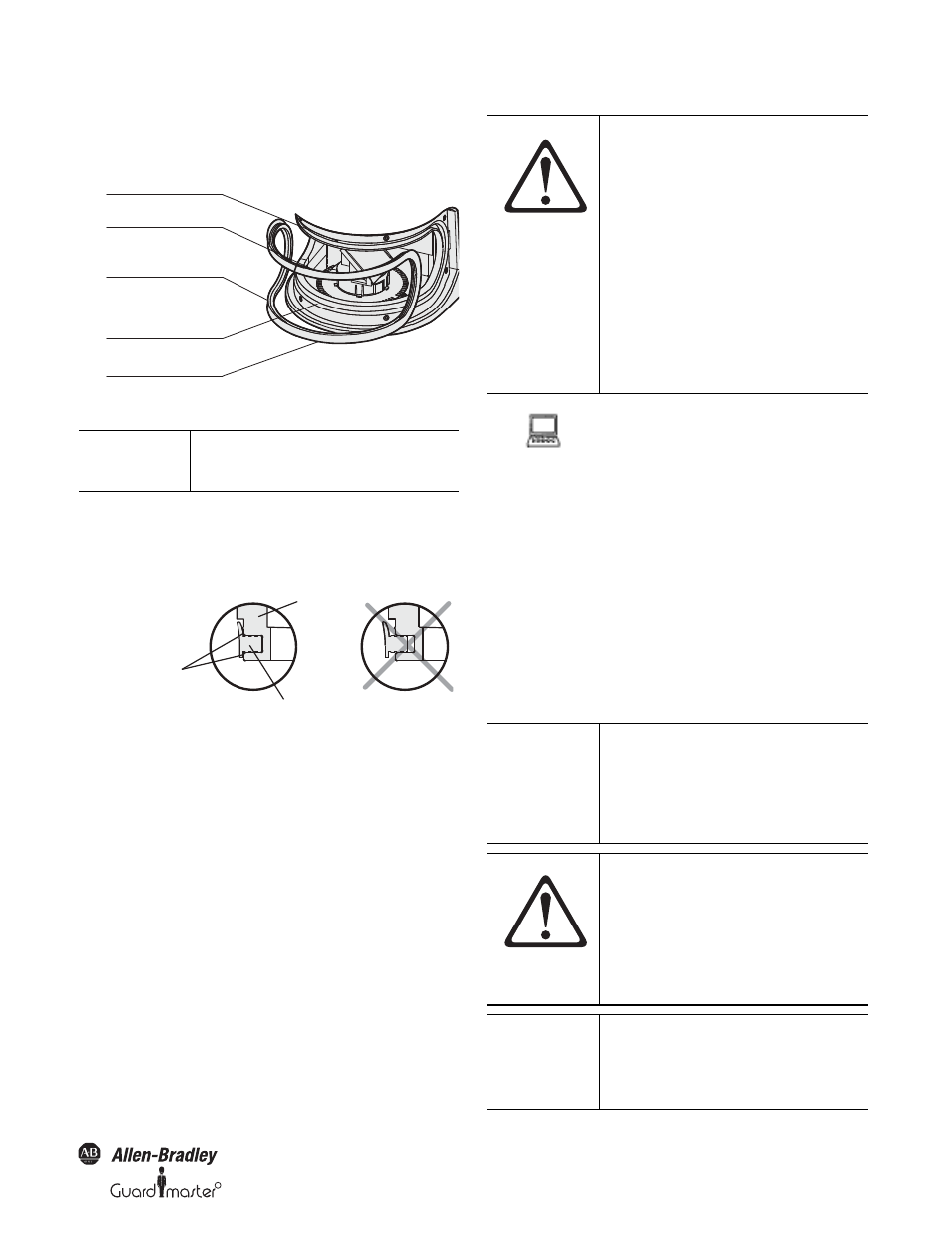

Figure 61: Inserting the rubber seal

² First place the seal only lightly in the rounded sections of the seal groove.

In this way you will avoid stretching the seal.

² Only then press the seal home. The seal should not be stretched on

insertion.

Figure 62: Depth for pressing in the seal

The seal is pressed in far enough when the edge of the seal and the sensor

head are flush.

² It is necessary to check that the seal is seated evenly all the way around the

groove.

² Check whether the mirror on the motor is clean and remove any

contamination with an optic brush.

² Set a torque wrench to 0.7 N•m or 6.2 in•lbf (hand-tight) for the use of

installing screws.

² Take the new front screen from the packaging.

² Remove any remnants of packaging.

² Place the front screen on the rubber seal and insert the new mounting

screws

to with spacers (see Figure 61).

² Press the front screen on the front of the cover. During this process

tighten the front screws

to to the torque set.

² Then insert the rest of the screws to with spacers (see Figure 61)

and tighten using the torque wrench.

Re-commissioning the SafeZone safety laser scanner:

² Re-mount the SafeZone safety laser scanner correctly (see Section 4

“Installation and mounting” on page 18).

² Connect the SafeZone safety laser scanner system connector.

After power up the SafeZone safety laser scanner automatically reads

the saved configuration from the system connector (see Section 8.3

“Re-commissioning” on page 37).

9.3 Replacing the I/O module

IMPORTANT

If the front seal is not inserted correctly,

the front screen may be damaged. Do

not use any pointed or sharp tools.

Seal edge flush with

housing edge

Seal

Housing

ATTENTION

Always perform a front screen

calibration with the aid of the SCD

software after the replacement of the

front screen.

The level of contamination is measured

continuously during the operation of

the SafeZone safety laser scanner. For

this purpose the front screen

calibration must first be performed;

this then serves as a reference for the

contamination measurement (status =

not contaminated).

The front screen calibration may only

be performed immediately after the

replacement of the front screen.

Device symbol SafeZone multizone safety laser

scanner, command Service, Front screen calibration.

The new front screen must be free of contamination

at the time of the front screen calibration. The front

screen calibration should be performed at room

temperature (10…30°C (50…86°F)).

IMPORTANT

²

The I/O module is only allowed to be

replaced by specialist personnel in a

clean environment.

²

Mount the I/O module as per the

following instructions to ensure that

the housing is sealed to IP65.

ATTENTION

While replacing the I/0 module, the

equipment may start inadvertently.

Switch the entire machine/system off

line.

As a matter of principle, always isolate

the machine from the power supply

during all work on the machine and

safety laser scanner.

IMPORTANT

When the I/O module is dismantled,

advanced electronic components are

accessible. Protect these from

electrostatic discharge, contamination

and moisture.