Original instructions, 1 stationary application in horizontal operation – Rockwell Automation 442L SafeZone Singlezone & Multizone Safety Laser Scanner User Manual

Page 21

R

SafeZone™ Safety Laser Scanner User Manual

10000073050, July 2011 19

Original instructions

The following steps are necessary after mounting and installation:

• Completing the electrical connections (Section 5 “Electrical installation”

on page 31)

• Configuration of the protective safety field (Section 7

“Configuration” on page 35)

• Commissioning and checking of the installation (Section 8

“Commissioning” on page 36)

• Checking of the SafeZone safety laser scanner functionality and safe

shutdown of the machine, vehicle or equipment (Section 8.2 “Test

notes” on page 36)

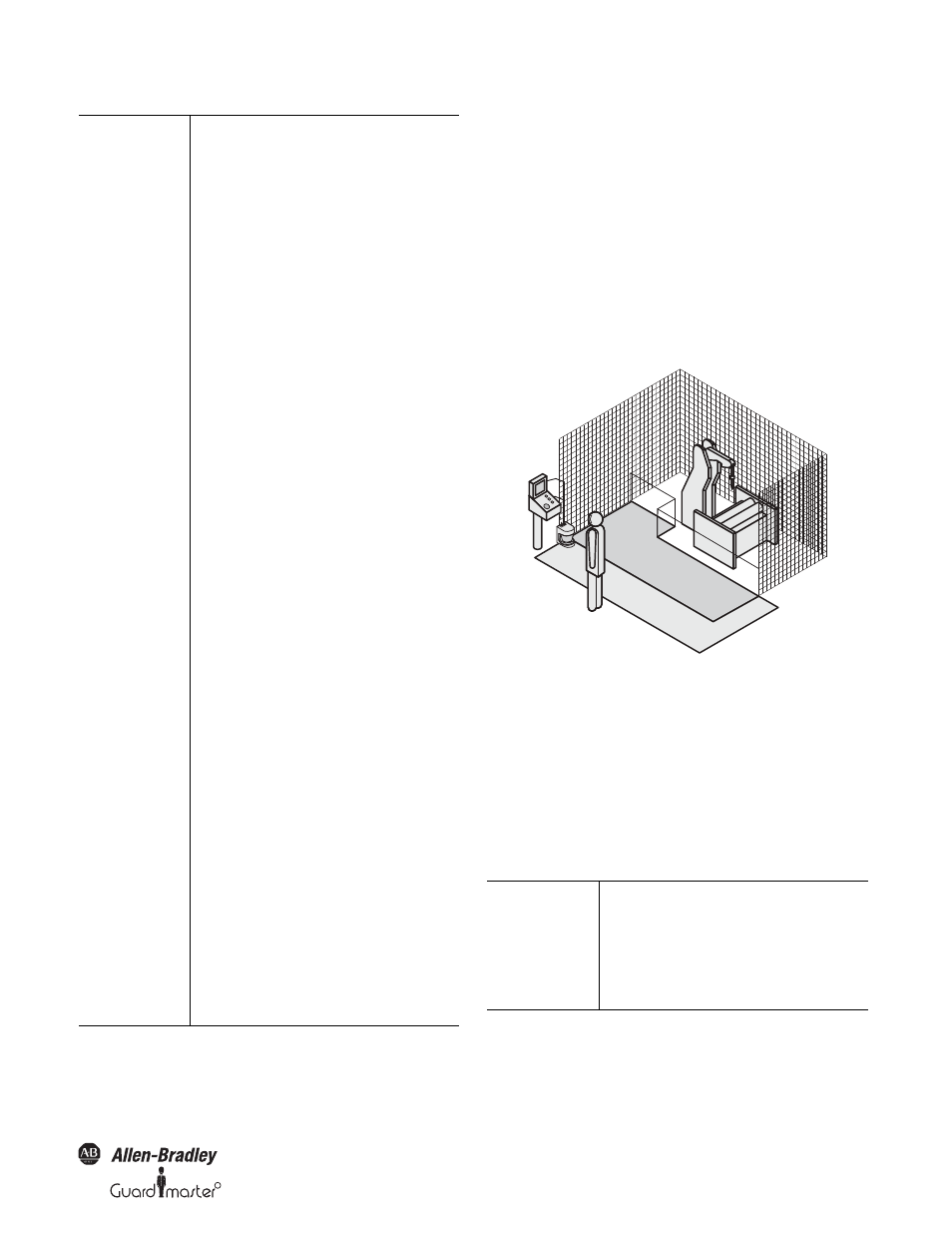

4.1 Stationary application in horizontal

operation

This type of protective device is suitable for machines and equipment on

which a hazardous area is not enclosed by a fixed protective device.

Figure 21: Horizontally mounted stationary application

For a horizontally mounted stationary application determine

• The protective safety field size to observe the necessary safety

distance.

• The height of the scan plane.

• The restart behavior.

• Measures to protect areas not covered by the SafeZone safety laser

scanner.

4.1.1 Protective safety field size

The protective safety field must be so configured that a safety distance

(S) to the hazardous area is maintained. This safety distance ensures that

the hazardous point can only be reached after the dangerous state of the

machine has been completely stopped.

IMPORTANT

• Mount the SafeZone safety laser

scanner in a dry place and protect

the device from dirt and damage.

• Avoid strong electrical fields.

These can be produced by

welding cables, induction cables in

the immediate vicinity and also by

mobile telephones operated in

close physical proximity.

• Ensure that there are no obstacles

in the area to be monitored in the

field of view of the SafeZone

safety laser scanner that could

cause interference or shadowing.

Such shadowed areas cannot be

monitored by the SafeZone safety

laser scanner. If there are

unavoidable shadowed areas,

check whether there is a risk. Take

additional safety precautions as

necessary.

• Keep the area to be monitored free

of smoke, fog, steam or other forms

of air impurities. Otherwise the

function of the SafeZone safety

laser scanner may be impaired

causing nuisance stops.

• Avoid placing highly reflective

objects in the scan plane of the

SafeZone safety laser scanner.

Examples: Retroreflectors can

affect the measurement results of

the SafeZone safety laser scanner.

Mirrored objects can hide part of

the area to be monitored.

• Mount the SafeZone safety laser

scanner such that it is not

saturated by incidental sunlight. Do

not position stroboscopic and

fluorescent lights directly in the

scan plane as these may affect the

SafeZone safety laser scanner in

specific circumstances.

• Mark the protective safety field on

the floor, if this is reasonable for

the application (see EN 61496,

part 1, Section 7).

IMPORTANT

Once you have defined the protective

safety field size, mark the boundaries of

the protective safety field on the floor.

This avoids inadvertent entrance into

the protective safety field and makes it

possible to subsequently check the

shape of the protective safety field.