10 corner bead and metal trim – USG Manufactured Housing Handbook User Manual

Page 9

Tips

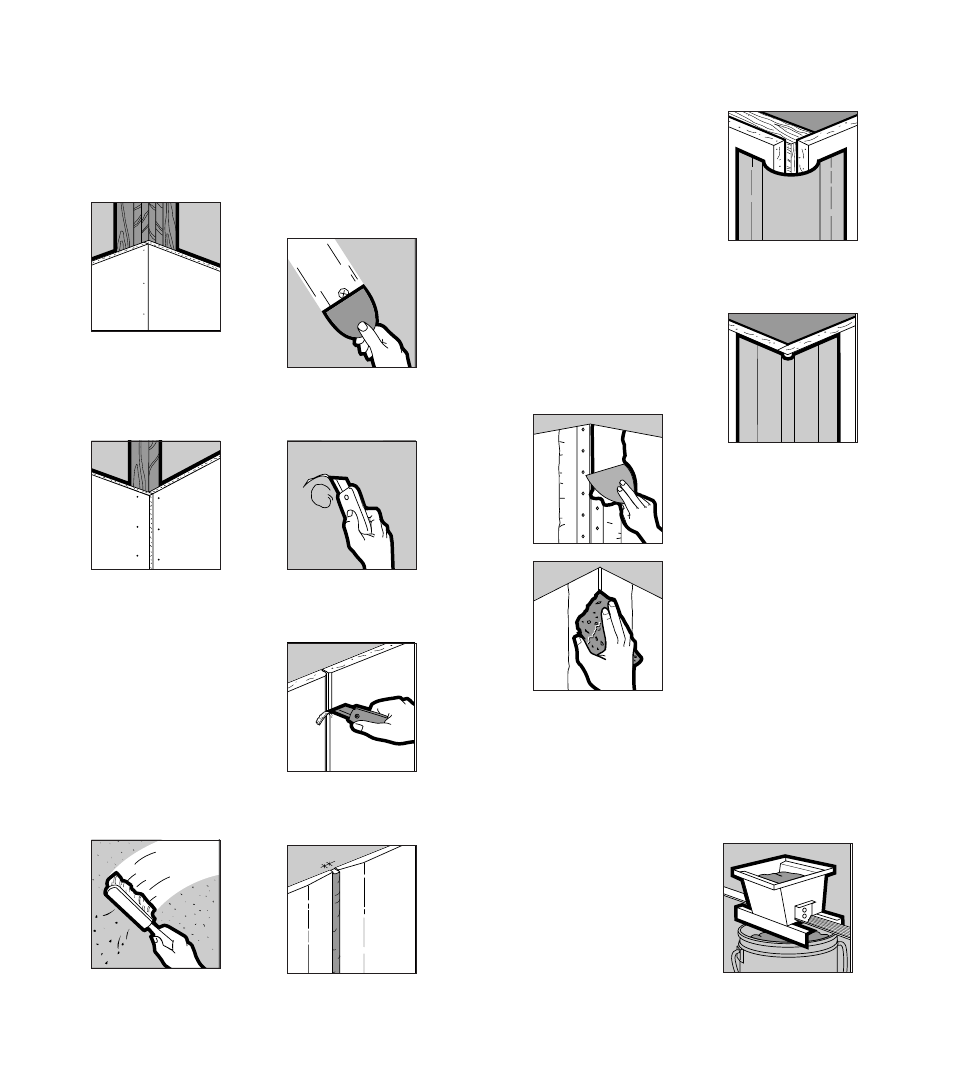

To join panels at an inside cor-

ner, butt the second panel

against the first and fasten the

end of the second to a stud.

To join panels at an outside cor-

ner, lap the end of the second

board over the end of the first,

and fasten both panel ends to

their common stud.

9 Drywall Inspection and

Preparation

After drywall installation, inspect

the surface you are going to fin-

ish. Drywall panels must be firmly

attached to the framing, properly

lined up, butted together, and not

damaged. Remove any drywall

dust or other particles from the

wall. Tape and joint compound will

not adhere well to dusty surfaces.

This can result in joint cracking,

and may cause the tape to sepa-

rate from the joint.

Make sure that your fasteners are

properly seated by drawing a

clean knife over each fastener. If

you hear a metallic ring, drive the

fastener below the surface. Be

careful not to break the face

paper.

Remove any loose paper, and cut

out any soft spots or bulges in the

board.

Butt joints, where cut board edges

meet, should be cut with a “V”

groove to remove fuzzed paper.

Deep holes and gaps larger than

1/8

Љ should be prefilled with joint

compound before finishing.

1 8"

/

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

10 Corner Bead and Metal Trim

S

HEETROCK

™

B

RAND

Paper Faced Metal

Bead and Trim

Apply compound to both sides of

corner, extending 2

Љ on each

side. Cut bead to desired length.

Align tightly, pressing firmly to set

bead. Be careful not to bend. Use

taping knife to embed bead firmly

into the joint compound by run-

ning the knife at a 45° angle over

the corner with even pressure.

Remove excess compound using

the knife to eliminate any air bub-

bles under the paper. Allow to dry.

Keep the nose of the bead clean

with a slightly damp sponge.

Tips

When bullnose bead is to be

applied to an outside corner, the

drywall panels forming the corner

should not be overlapped. This

will permit the rounded bead to fit

snugly around the corner. (For

inside corners, no special align-

ment of panels is necessary to

accommodate bullnose bead.)

If regular right-angle bead is to be

used for an outside corner, the

boards should overlap as usual.

Application of paper-faced metal

bead will be quicker and easier if

you apply compound to the bead

using a hopper. This is a simple

piece of equipment that spreads

compound on the bead as you

pull it through the hopper’s spe-

cially designed openings or

gates. For best results, you

should place the hopper on a

plastic pail to collect any excess

compound. Cut “V” shapes out of

the pail on both sides so that the

bead can enter and exit smoothly

as you push it through the hop-

per.

The hopper has two differently

shaped gates. One is for right-

angle bead, and one is for bull-

nose bead.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

17

16

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........