USG Manufactured Housing Handbook User Manual

Page 7

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

13

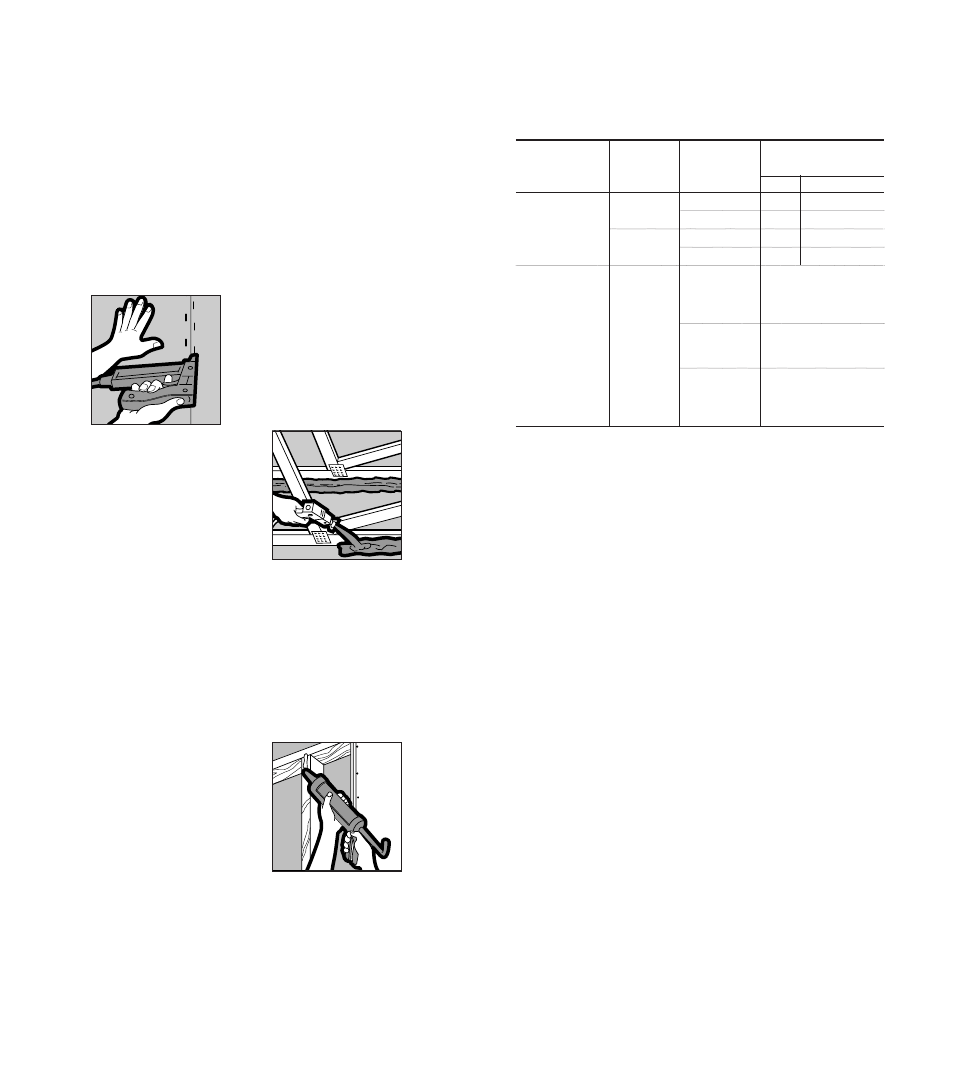

Staple Attachment

Drywall can be secured using sta-

ples; however, wide-crown fas-

teners are difficult to conceal dur-

ing finishing. Use minimum 7/16

Љ

crown staples with 1-1/8

Љ legs for

1/2

Љ and 3/8Љ gypsum board, and

with 1-1/4

Љ legs for 5/8Љ board.

Space staples 7

Љ o.c. for walls

and ceilings.

6 Adhesive Attachment

The use of adhesive to attach

gypsum panels to wood framing

can reduce, or, in some cases,

eliminate the number of mechani-

cal fasteners required. The table

below provides general guidelines

for the spacing of mechanical fas-

teners used in conjunction with

adhesives. The recommendations

of the adhesive manufacturer

must be followed.

Caution: Certain wall and ceiling

assemblies in a manufactured

home are designed to resist wind

and transportation loads. These

assemblies must be constructed

in accordance with the specifica-

tions outlined in the test report

chosen by the design engineer.

General guidelines do not apply to

these assemblies.

A urethane foam adhesive is avail-

able for attaching gypsum panels to

wood framing. A two-component

urethane adhesive is spray-applied

to the intersection between the side

of the framing member and the back

of the gypsum panel. Immediately

after spraying, the urethane foams in

place to create a fillet-type of bond.

Mechanical fasteners are not typi-

cally required when using this

method. Take precautions to avoid

framing displacement during the

foaming process. Contact the adhe-

sive manufacturer for equipment

requirements and installation

instructions.

Select the proper adhesive for spe-

cific job requirements. Make sure

that framing is clean, sound and free

from oil, dirt or contamination. Apply

adhesive and fasteners per instruc-

tions on adhesive cartridge. Do not

use adhesive alone to secure panels

unless specifically recommended by

the adhesive manufacturer.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

Gypsum Wallboard

Installation

General recommendations for

gypsum panels applied to wood

framing:

– Cut boards so that they touch

but are not forced into position.

Butt all joints loosely.

– Whenever possible, place

tapered or wrapped edges next

to one another.

– Whenever possible, apply

boards perpendicular to framing

and in lengths that will span

ceilings and walls without creat-

ing end (butt) joints. If butt joints

do occur, stagger and locate

them as far from the center of

walls and ceilings as possible.

– Support all ends and edges of

gypsum board on framing,

except long edges at right

angles to framing and where

end joints are to be floated

between frame members and

back-blocked.

– When fastening, apply hand

pressure on panel next to fas-

tener being driven to ensure

panel is in tight contact with

framing member.

– If metal trim is to be installed

around edges, doors, or windows,

determine if trim is to be installed

before panel application.

– Do not anchor panel surfaces

across the flat grain of wide

dimensional lumber such as floor

joists and headers. Float panels

over these members or provide a

control joint to compensate for

wood shrinkage.

Measurements—All measurements

must be accurate. Make two mea-

surements as a check. Measure

across the diagonal corners of wall

and ceiling framing laid out on the

assembly fixture. This procedure will

usually warn of assemblies that are

out of square. Then, framing correc-

tions can be made before the board

is attached.

Cutting—Make straight-line cuts

across full width or length of board by

scoring the face paper, snapping the

board core, and then cutting the back

paper. The common tool used to

score and cut gypsum board is a util-

ity knife with replaceable blade.

Regardless of the type of knife used,

...............................................................................................................................

........................................................................................................................

12

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

Maximum Fastener Spacing

Gypsum Panel Constructions—Wood Framing

Maximum Fastener Spacing

Construction

Fastener

Gypsum Panels

Type

Type

Location

in.

mm

Single Layer—

nails

ceilings

7

178

Mechanically Attached

sidewalls

8

203

screws

ceilings

12

305

sidewalls

16

406

Single Layer—

nails/

ceilings

16

Љ or 406 mm o.c. at ends,

Adhesively Attached

screws

(perpendicular)

edges—1 field fastener per

frame member at mid-width

of board

ceilings

16

Љ or 406 mm o.c. along each

(parallel)

edge and 24

Љ or 610 mm o.c.

along intermediate framing

walls

16

Љ or 406 mm o.c. at ends,

(perpendicular)

edges—1 field fastener per

frame member at mid-width of

board