Repairing damaged panels – USG Manufactured Housing Handbook User Manual

Page 22

Repairing Damaged Panels

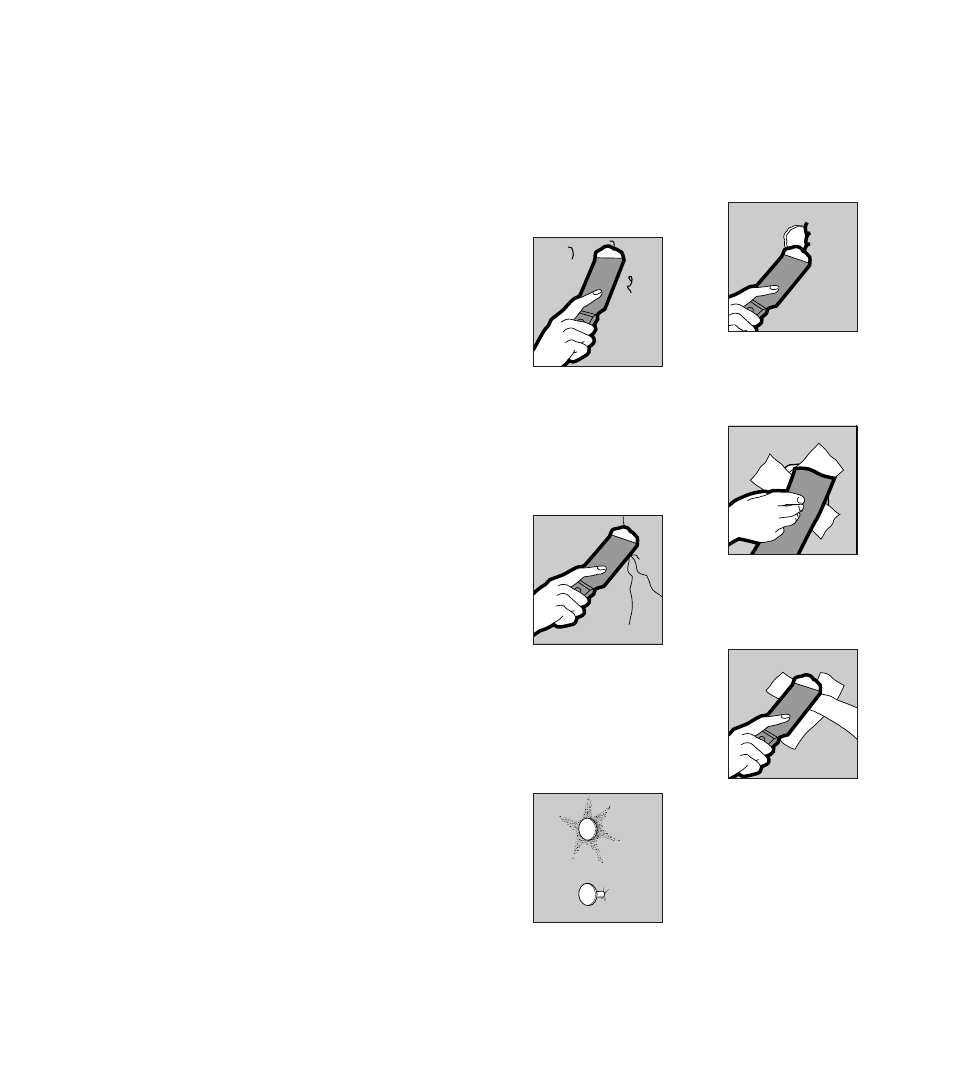

1 Patching Dents, Holes,

Popped Nails and Cracks

a To repair a dent, sand and then

fill with lightweight setting-type

joint compound. Let harden.

Add second coat if necessary.

Sand and prime when dry.

b To repair a small hole or crack,

wipe area clean. Fill with light-

weight setting-type joint com-

pound, using a putty knife. Let

harden. Add second coat if nec-

essary. Sand and prime when

dry.

c To repair a popped nail, drive

and dimple new nail 1-1/2

Љ

from popped nail. Drive and

dimple popped nail. Cover with

lightweight setting-type joint

compound. Sand and prime

when dry.

2 Patching Medium Holes

a Apply generous amounts of

lightweight setting-type joint

compound around edges and

coat the perimeter of hole.

b Crisscross two or three strips of

joint tape over opening and

embed tape in joint compound.

Let harden.

c Apply coat of joint compound

over taped area. Let harden

and apply second coat; sand

and prime when dry.

PANEL 61

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

43

Before applying subsequent

coats, fill fastener depressions

using a hand knife or nail spotter.

6 Finishing

When the taping coat is dry, use a

7

Љ-10Љ box finisher to apply the

next coat of compound on flat

joints. Allow the compound to dry,

then sand lightly.

Apply the finish coat, using a 12

Љ

box for flat joints, and a 2

Љ-3Љ cor-

ner finisher (attached to the cor-

ner pump or angle applicator) for

inside corners.

Apply a finish coat to fasteners.

Scrape away excess compound

and fill in voids using a hand

knife. Sand as needed.

Alternative Method (Banjo)

The banjo offers an alternative finish-

ing method that is especially good for

small jobs.

First, apply tape and compound to

joints using the banjo.

Before applying subsequent coats,

fill fastener depressions using hand

knife or nail spotter.

When the taping coat has dried, apply

a fill coat of compound using hand

tools. Allow to dry and sand lightly.

Apply a final coat of compound using

a 12

Љ box for flat joints and a 3Љ cor-

ner finisher (attached to corner pump

or angle applicator) for inside cor-

ners.

Scrape away excess compound and

fill in voids using a hand knife. When

compound is dry, sand lightly as

needed.

7 Maintenance and Cleanup

Never permit setting-type com-

pound to harden inside a tool; this

will make the tool difficult or

impossible to clean. Water does

not prevent the chemical harden-

ing of setting-type compounds.

For drying type compound, if you

will not be using a tool for more

than 5 minutes, place it in a

bucket of water. Keeping tools

clean is important, because dried

material built up on and inside

tools will hinder their operation.

Keep moving parts on mechanical

tools lubricated with oil. Blades on

these tools are replaceable, and

need to be changed regularly. For

specific instructions on mainte-

nance, consult the tool manufac-

turer’s recommendations.

Use of cleaning station equipment

makes the cleaning of mechanical

drywall tools quicker and easier,

particularly when setting-type

compounds are used. USG offers

S

HEETROCK

™

Cleanser (available

through the cleaning station man-

ufacturer) to aid in the cleansing

process.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

42

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........