USG Manufactured Housing Handbook User Manual

Page 13

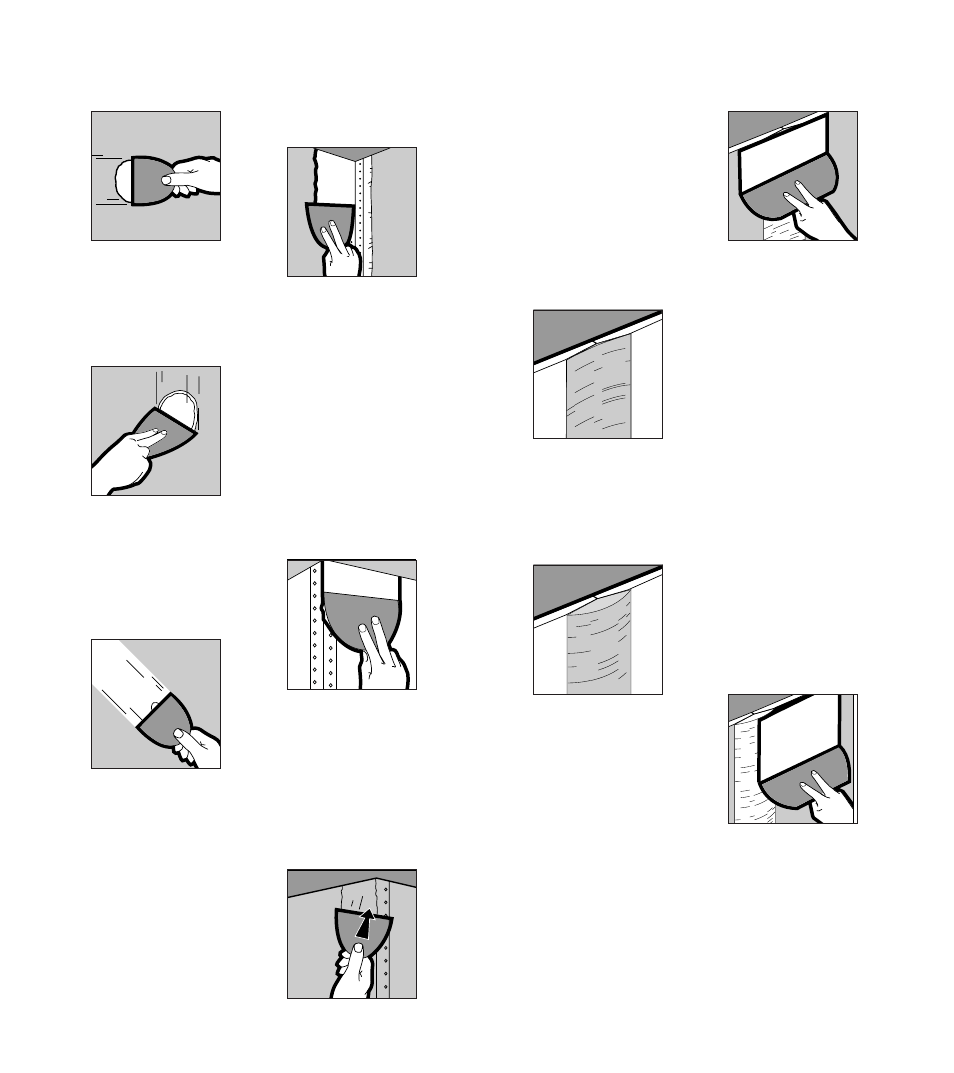

Then raise the knife blade to a

more upright position and scrape

off excess with a second stroke at a

right angle to the first stroke.

Compound should be level with

panel surface.

Tip

To determine if fasteners are

properly seated prior to finishing,

draw clean knife over each fas-

tener. If metallic ring occurs, drive

fastener below surface, being

careful not to break paper.

15 First Coat—Bead and Trim

Paper-Faced Metal Corner Bead and

Trim (Tape On)

Using a 6

Љ-8Љ taping knife, apply a

coat of S

HEETROCK

MH Brand

Setting-Type Joint Compound to

both sides of the corner. Keep this

coat as smooth as possible,

feathering it out 5

Љ-6Љ on each

side. Let dry. Sand sides lightly

where necessary. L-Trim and

Reveal Trim are finished in a

similar manner, except that only

one side is finished.

Other Types Metal Corner

Bead and Trim

Apply S

HEETROCK

MH Brand

Setting-Type Joint Compound

with 8

Љ knife onto one flange of

the corner bead. Work down the

entire length of the bead. Hold

knife at 45° angle and smooth

compound—one edge of knife

riding the metal, the other on the

surface of the panel. Compound

should extend onto panel a mini-

mum of 4

Љ. Repeat application for

other flange. Use same applica-

tion method for metal trim.

Tip

After filling first flange, the metal

corner edge may have some

lumps of joint compound. To

remove, run 8

Љ blade up the bead

while also moving it to the side. In

this way, the compound is contin-

uously moved aside as it is

scraped off.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

16 Second Coat, Flat Joints and

Fasteners

Tips

At this stage of finishing, tapered

joints and butt joints need to be

treated differently. Because

tapered joints provide a depres-

sion for the tape and compound,

there is a danger that the depres-

sion will remain incompletely

filled, resulting in a starved joint.

Butt joints, on the other hand, are

naturally crowned, because the

tape and compound have to be

placed above the surface of the

board. Excess compound will

result in a crowned joint.

To prevent starved and crowned

joints, two different techniques of

applying joint compound are

used. These are known as “cen-

tering” and “splitting.” You should

center a tapered joint by first run-

ning the knife down the center,

then up one side, then down the

other, then down the middle

again. This will ensure that the

depression created by the tapers

will be filled.

The tapered joint should then be

feathered, with the compound

spread out very thin at the edges.

To feather, press down on the

edge of the knife that is furthest

from the joint, and lift the other

edge very slightly.

When treating a butt joint, the goal

is to make the joint’s natural

crown as invisible as possible.

This is accomplished by finishing

the sides of the joint so that the

slope from the center of the joint

down to the level of the board is

extremely gradual. The technique

used to achieve this effect is

known as “splitting the joint,”

because you treat the sides first,

then wipe down the middle. On

each side, use the feathering

technique to make sure that the

thickness of the compound

changes as gradually as possible.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

25

24

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........