Decorating products preparing the panels – USG Manufactured Housing Handbook User Manual

Page 5

Priming

S

HEETROCK

Brand First Coat

is a flat latex paint specially formu-

lated to provide an excellent first

(prime) coat over gypsum panels.

Conventional sealers help eliminate

porosity variations, but typically won’t

correct texture variations.

Conventional paint primers, on the

other hand, help correct texture dif-

ferences but usually will not equalize

porosity. First Coat is unique because

it minimizes both texture and porosity

differences for easy, problem-free

decorating. Not intended as a finish

coat, and is not a vapor-retardive

coating.

Textures

Aggregated Versus Unaggregated

Textures

Aggregated textures contain clearly

visible particles that “stand

out” when dry for a texturing effect

similar in appearance to acoustical

ceiling finish. Unaggregated texture

does not contain such particles; its

final appearance is determined

largely by the method of application.

S

HEETROCK

®

MH Brand Aggregated

Ceiling Spray Texture (T

UF

-S

PRAY

Medium and Coarse)

produces a handsome simulated

acoustical ceiling finish (with no

acoustical correction). It mixes easily,

offers excellent coverage with low

aggregate bounce-back during spray-

ing, and masks minor surface defects.

Available in medium and coarse.

S

HEETROCK

®

MH Brand Unaggregated

Spray Texture (T

UF

-T

EX

)

is an unaggregated texture for use on

interior walls and ceilings in manufac-

tured housing. It can be easily applied

using spray equipment, brush, or

roller, and produces a variety of tex-

ture patterns from bold spatter/

knockdown to light orange peel.

S

HEETROCK

Brand Ceiling Spray Texture

(QT)

is available aggregated with perlite,

polystyrene, or poly/perlite, and in

fine, medium, and coarse versions. It

offers excellent hide and firmness,

and dries to a white finish.

S

HEETROCK

®

Brand Wall and Ceiling Spray

Textures (Aggregated and

Unaggregated)

produce a variety of texture patterns

from bold spatter/knockdown to fine

orange peel. Provide superior cover-

age and help conceal minor substrate

defects. Application by spray and/or

hand-tooled by broad knife, brush, or

roller, depending on pattern desired.

S

HEETROCK

®

Brand Wall and Ceiling

Texture (Multi-Purpose)

is an unaggregated texture coating

for producing fine to medium texture

patterns (such as fine orange peel

and crowsfoot-stipple finishes) on

walls and ceilings. Textured effect

obtained by brush, roller, or spray

application. Helps conceal minor sur-

face defects.

S

HEETROCK

®

Brand Wall and Ceiling Spray

Texture (Sand Finish Texture 12)

is a powder product producing a fine

sand finish on walls and ceilings.

Combines easy mixing, fast drying,

excellent coverage, and good con-

cealment. Apply by spray application

only. An ideal base for wall paints;

may be left unpainted on ceilings.

S

HEETROCK

®

Brand Wall and Ceiling

Texture Paints

are also available in ready-mixed

form, including Sand Finish Texture

1, Ripple Finish Texture 2, and

T

EXOLITE

Sanded Paste Stipple.

For a complete description of all the

textures and finish products available

from USG, please consult United

States Gypsum Company publication

SA933.

Decorating Products

Preparing the Panels

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

Read all instructions through before

installing gypsum panels. Prepare a

plan for each assembly to be con-

structed, and ensure that you have

the right sizes of board, sorted in the

right quantities, to avoid extra han-

dling. A rolling cart at the assembly

can be easily loaded from a fork lift

in the material aisle, then moved up

and down the fixture as needed to

reduce the carrying required.

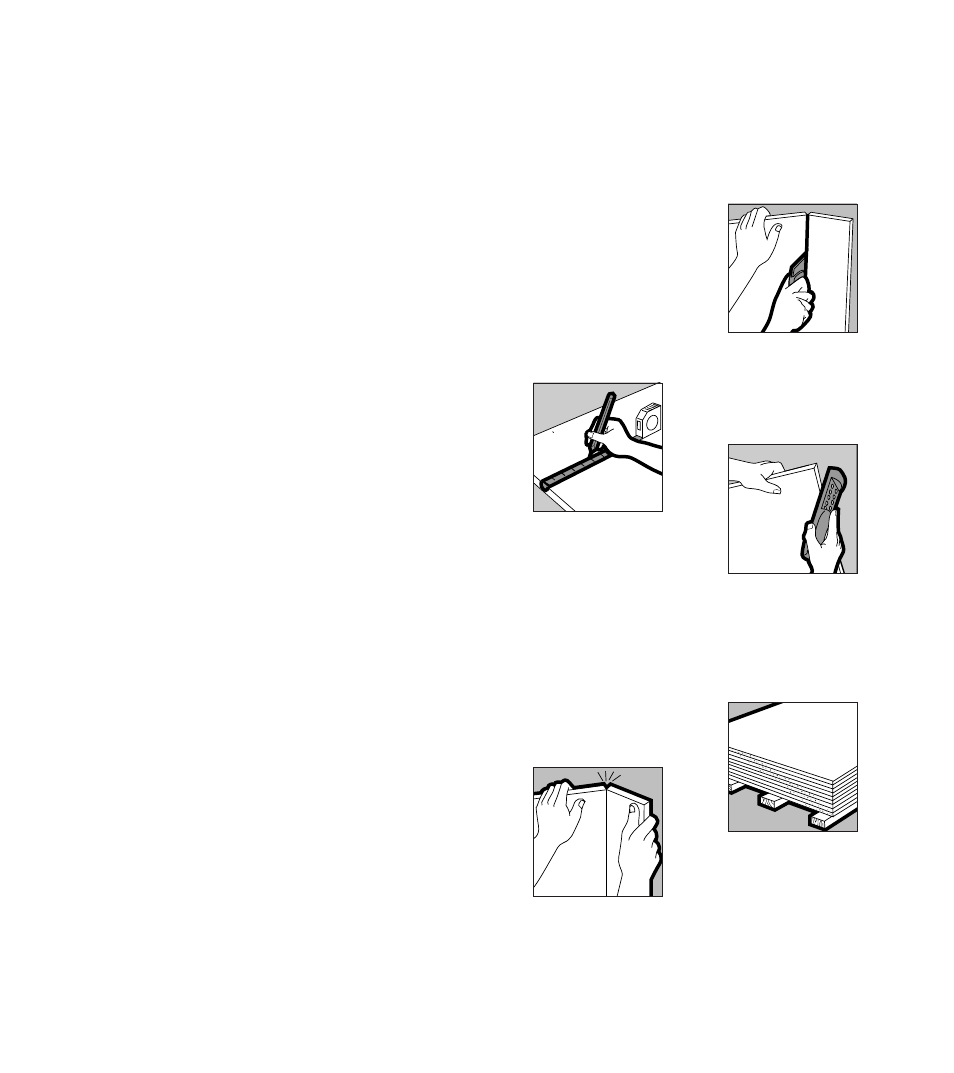

1 Marking

Measure and mark panel size

desired.

2 Cutting

Line up straightedge with the

marks and hold firmly against the

panel. Draw pencil line as guide

for scoring. Score through paper

and lightly into the core with a

sharp utility knife.

To break the panel core, securely

grasp the board edges on both

sides of the score line and snap

board with a quick, firm move-

ment.

Use utility knife with sharp blade

for scoring. Complete cutting by

running knife through back paper

for the length of the panel and

snapping back to face.

After cutting the panel, smooth

the cut edge with a rasp. Be sure

to keep edge as square as possi-

ble. Always wear a dust mask

when sanding or rasping.

Tip

Gypsum panels are heavy and

may bend or snap under their

own weight. Be sure panels are

properly supported prior to

scoring.

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........

9

8

...............................................................................................................................

...............................................................................................................................

...............................................................................................................................

...........